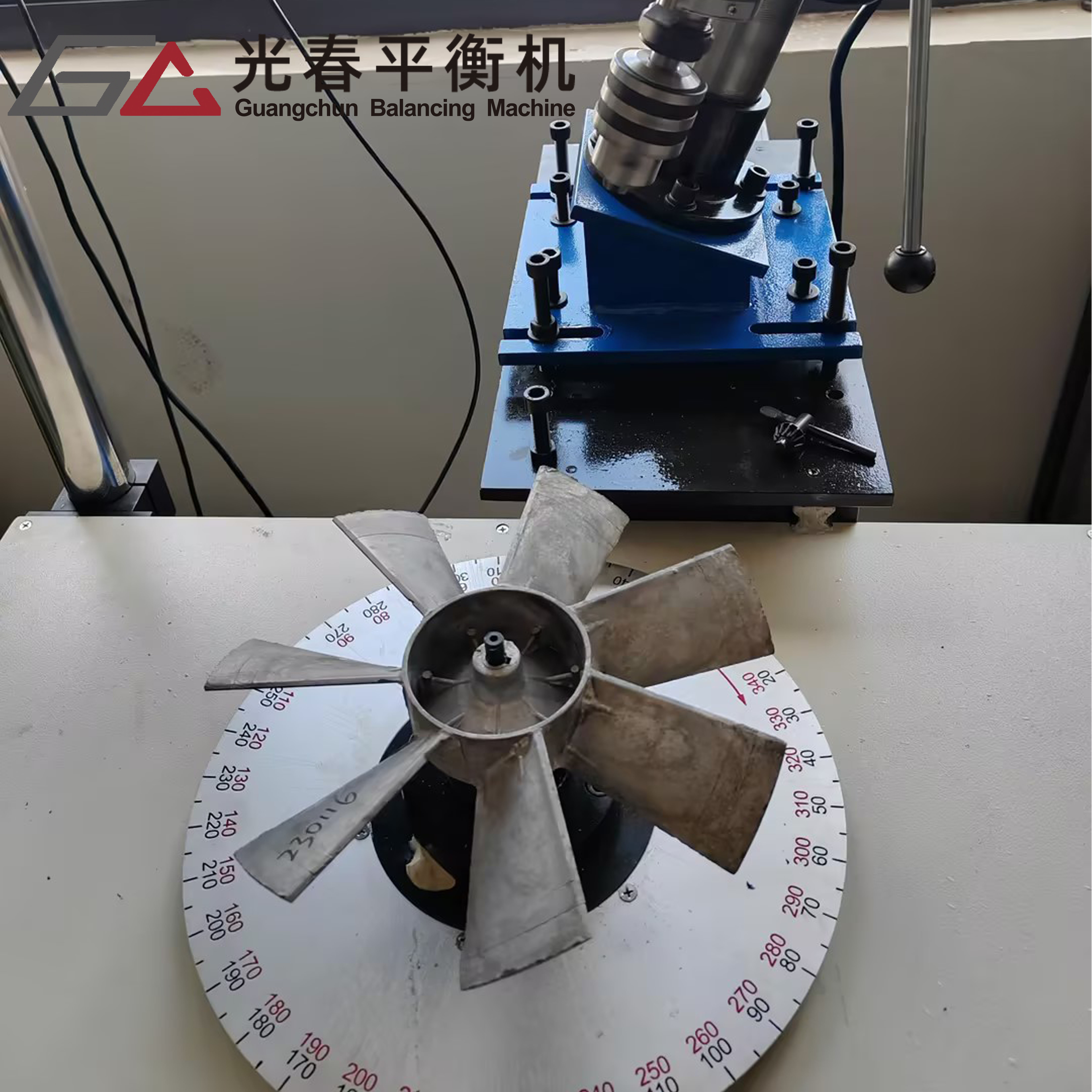

dynamic balancing machine

A dynamic balancing machine is a sophisticated piece of equipment designed to detect and correct imbalances in rotating components. This precision instrument measures the distribution of mass in rotating parts, ensuring they spin smoothly without vibration. Operating through advanced sensors and computer-controlled systems, the machine detects even minute imbalances that could cause equipment failure or reduced performance. The machine works by rotating the component at specific speeds while sensitive measuring devices detect any uneven weight distribution. Modern dynamic balancing machines incorporate digital technology for real-time analysis and automatic correction calculations. These machines are essential in manufacturing industries where rotating parts must maintain precise balance for optimal performance. They can handle various component sizes, from small turbine rotors to large industrial fans, making them versatile tools in quality control processes. The technology employs both soft-bearing and hard-bearing systems, allowing for flexibility in testing different components. Dynamic balancing machines significantly improve product quality, reduce maintenance costs, and extend equipment lifespan through precise balance correction.