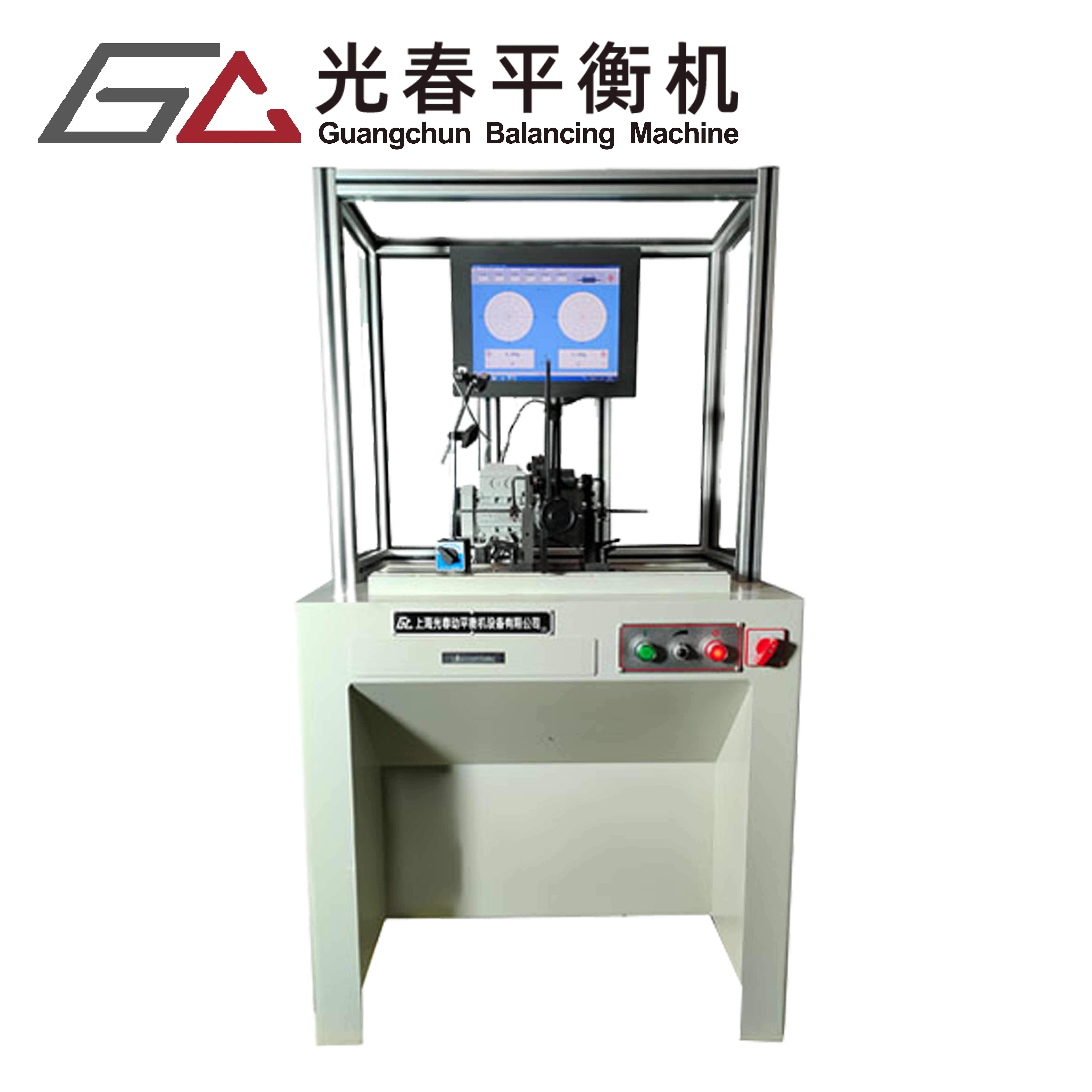

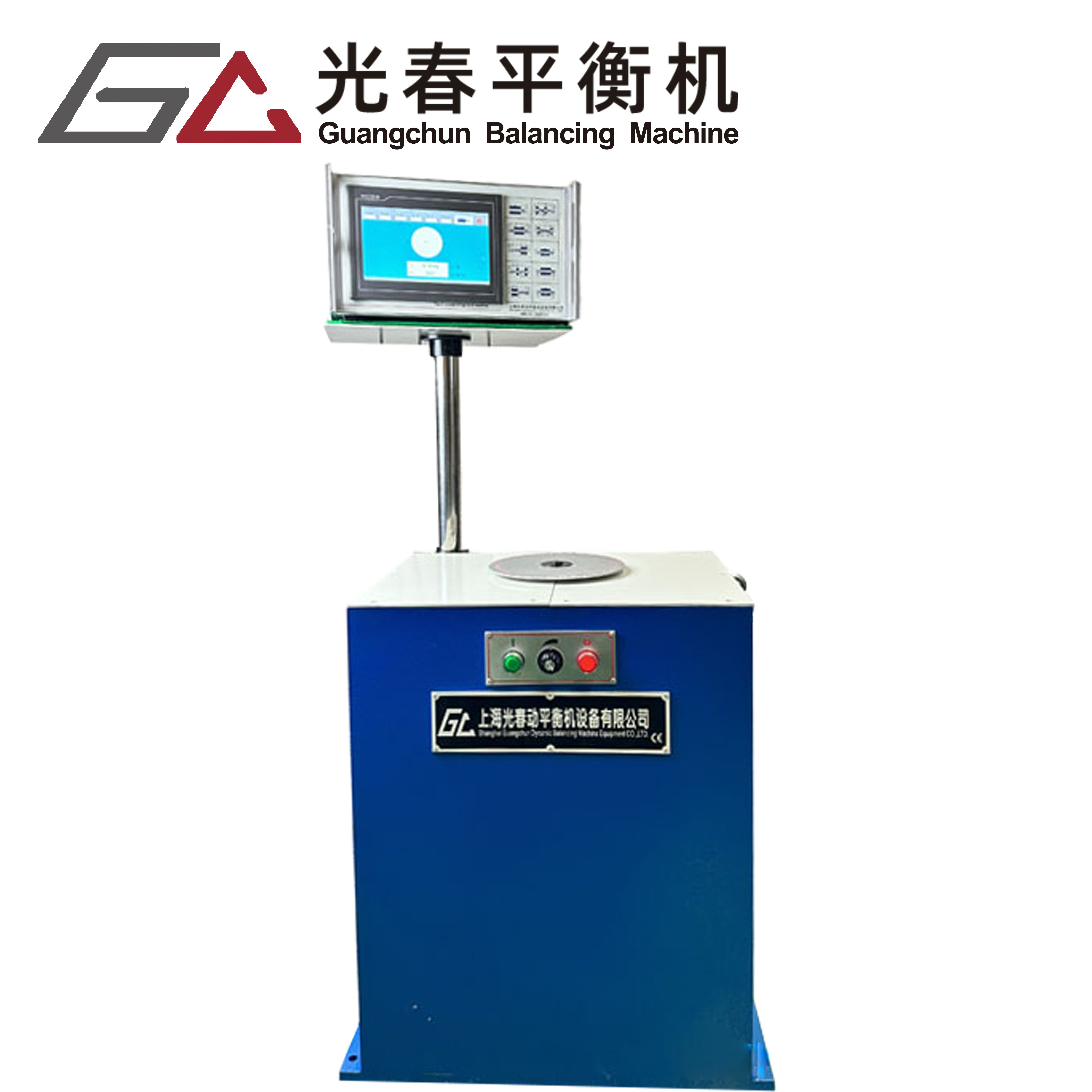

field balancing machine

A field balancing machine is an essential diagnostic and maintenance tool designed to measure and correct rotational imbalance in machinery while operating in its installed location. This sophisticated equipment employs advanced sensors and digital technology to detect vibration patterns, analyze dynamic forces, and precisely calculate the required corrections for optimal balance. The machine operates by measuring vibration at specific points on the equipment, typically using accelerometers or velocity sensors, and processes this data through specialized algorithms to determine the location and magnitude of imbalance. Field balancing machines are particularly valuable because they enable on-site balancing without the need for equipment dismantling, significantly reducing maintenance downtime and associated costs. These machines find extensive applications across various industries, including power generation, petrochemical processing, paper manufacturing, and HVAC systems. They are especially crucial for maintaining large rotating equipment such as industrial fans, blowers, turbines, and pumps. The technology incorporates real-time monitoring capabilities and can handle both single-plane and dual-plane balancing operations, making it versatile for different types of rotating equipment. Modern field balancing machines often feature user-friendly interfaces, automated calculation processes, and comprehensive reporting functions that help technicians achieve precise balance corrections efficiently.