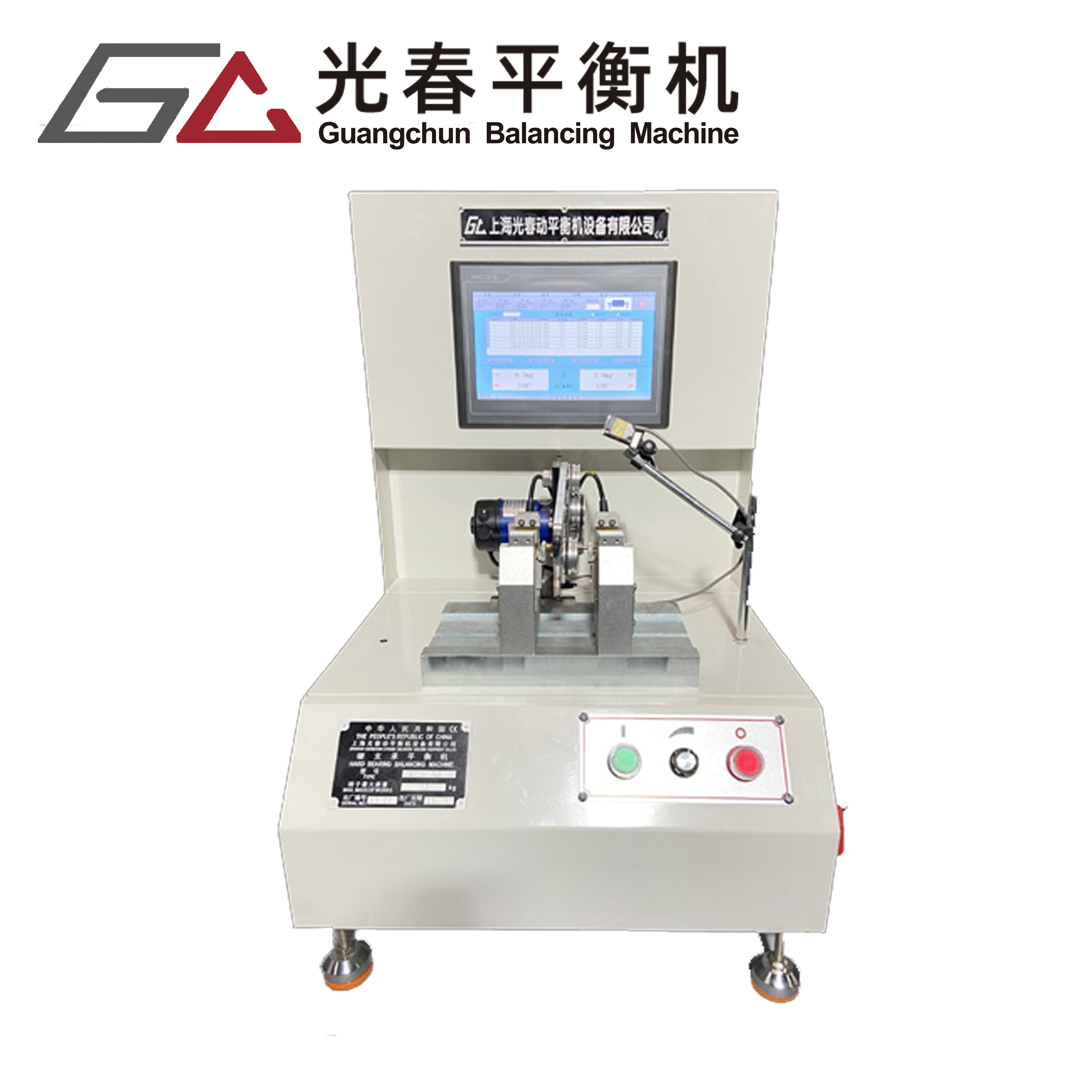

highefficiency motor balancing solutions

High-efficiency motor balancing solutions represent a cutting-edge approach to maintaining optimal performance in rotating machinery. These advanced systems combine precision measurement technology with sophisticated analysis tools to ensure motors operate at peak efficiency. The solutions incorporate state-of-the-art vibration analysis equipment, dynamic balancing techniques, and real-time monitoring capabilities to detect and correct imbalances before they cause significant issues. Using advanced sensors and digital processing technology, these systems can identify microscopic variations in motor rotation, allowing for precise adjustments that enhance performance and extend equipment life. The solutions are designed to work across various motor types and sizes, from small industrial motors to large heavy-duty applications. They employ both static and dynamic balancing methods, utilizing computerized analysis to determine exact correction weights and positions. These systems can detect multiple types of imbalance, including static, couple, and dynamic imbalances, providing comprehensive diagnostic information for maintenance teams. The technology integrates seamlessly with existing maintenance programs, offering both preventive and predictive maintenance capabilities to reduce downtime and optimize operational efficiency.