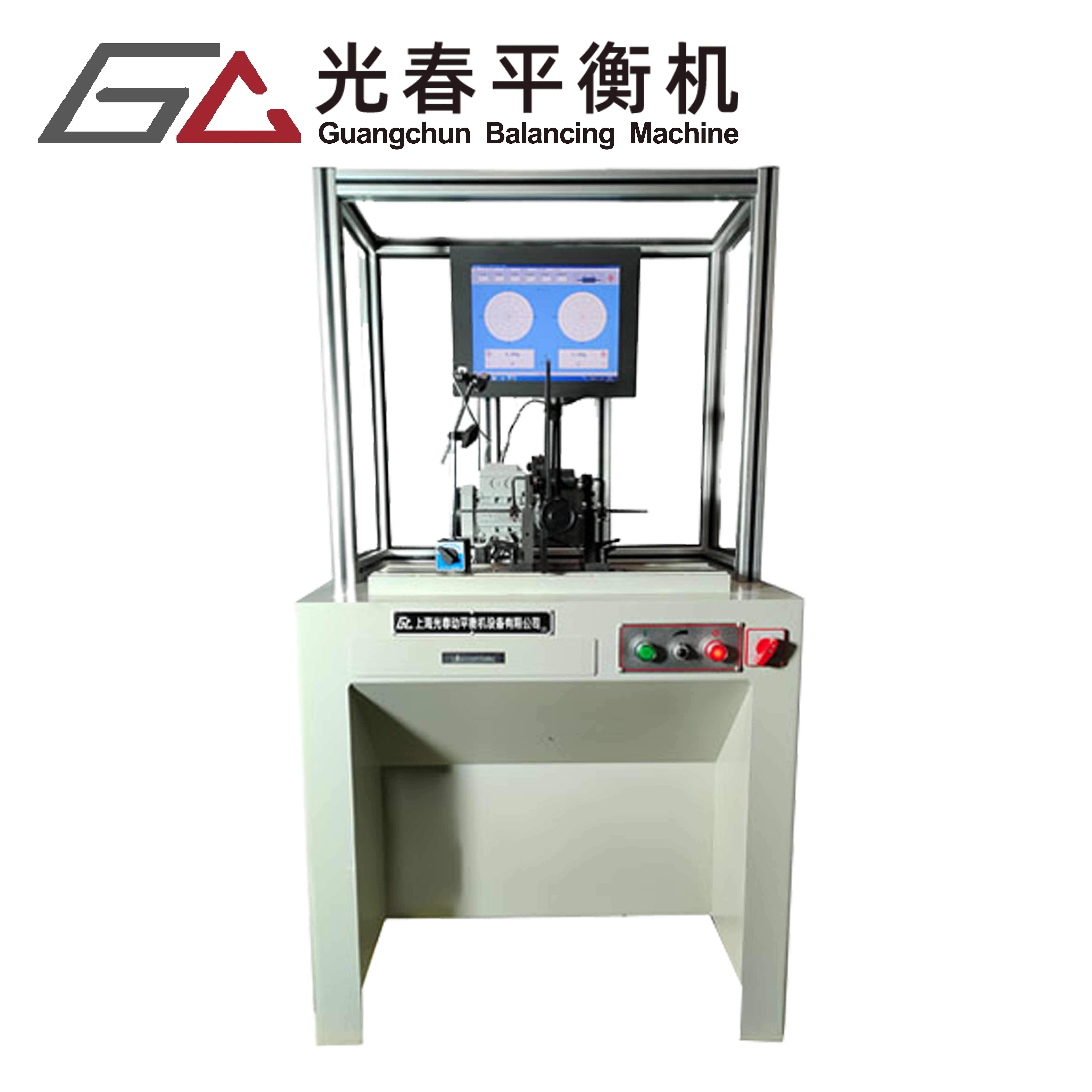

balancing equipment

Balancing equipment represents a crucial advancement in industrial machinery maintenance and operation, offering precise measurement and correction of rotational imbalances in various mechanical components. These sophisticated systems combine cutting-edge sensors, digital processing technology, and precision measurement capabilities to detect and analyze vibration patterns, ensuring optimal performance of rotating equipment. The equipment utilizes advanced algorithms to calculate exact imbalance locations and required correction weights, enabling technicians to achieve perfect balance in rotors, fans, turbines, and other rotating machinery. Modern balancing equipment features user-friendly interfaces, real-time monitoring capabilities, and automated calibration systems that maintain accuracy throughout extended operation periods. The technology incorporates both horizontal and vertical balancing planes, allowing for comprehensive analysis and correction of dynamic imbalances. These systems can handle components ranging from small precision parts to large industrial rotors, with some models capable of managing weights up to several tons. The equipment typically includes high-sensitivity vibration sensors, digital displays, and computer-integrated analysis software that provides detailed reports and recommendations for balance corrections. Additionally, many systems feature automated documentation capabilities, ensuring compliance with industry standards and maintaining detailed service records.