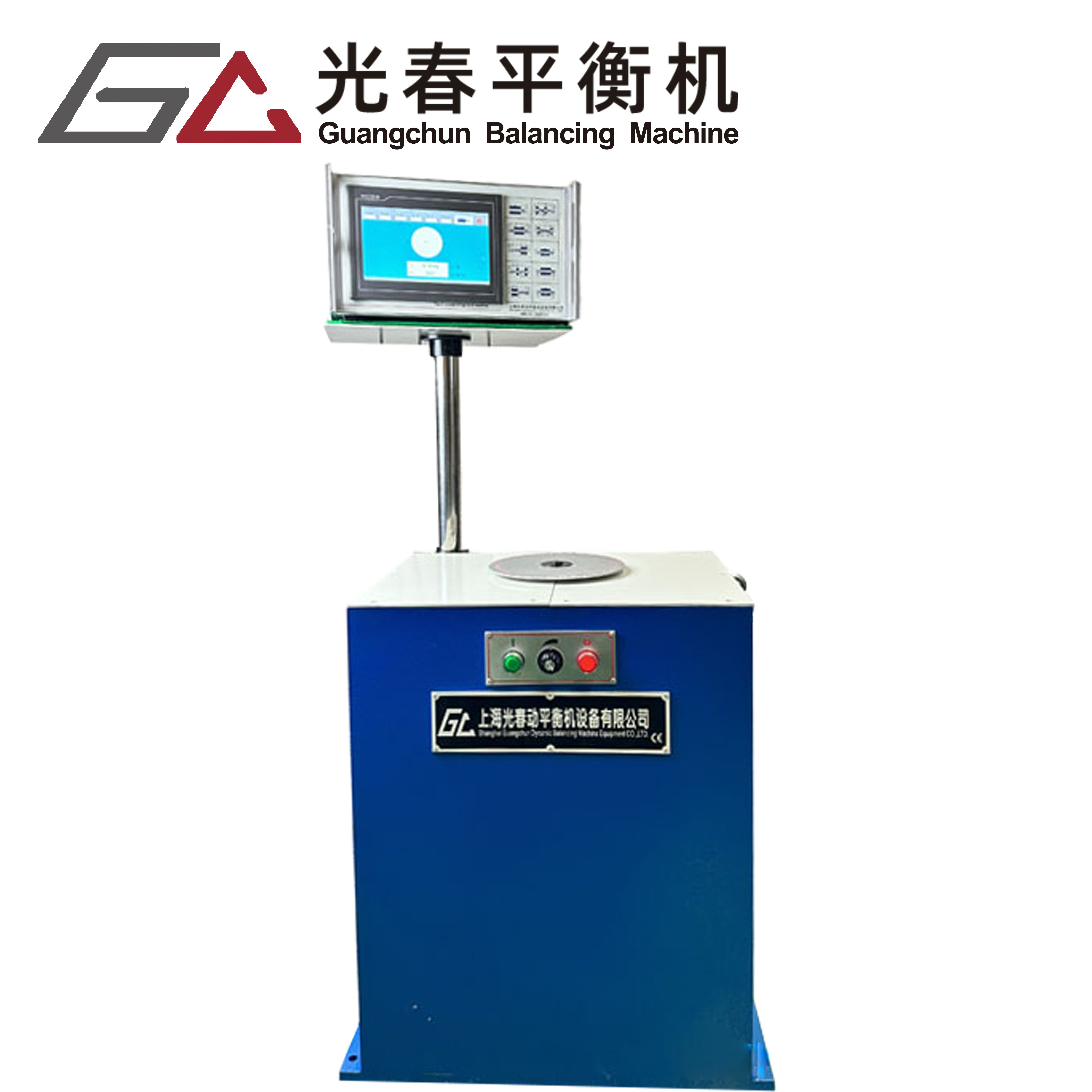

cross flow balance machine

The cross flow balance machine represents a sophisticated piece of industrial equipment designed to achieve precise dynamic balancing of rotary components. This advanced machinery utilizes cutting-edge cross flow technology to detect and correct imbalances in rotating parts, ensuring optimal performance and longevity of industrial equipment. The machine operates by analyzing the distribution of mass across rotating components through sophisticated sensors and digital processing systems. It can handle a wide range of parts, from small precision components to large industrial rotors, making it versatile for various manufacturing applications. The machine's core technology incorporates dual-plane balancing capabilities, allowing for simultaneous correction of both static and dynamic imbalances. Its automated measurement system provides real-time data analysis, enabling operators to make precise adjustments with minimal manual intervention. The cross flow design ensures uniform air distribution during the balancing process, resulting in more accurate measurements and consistent results. The machine features an intuitive interface that guides operators through the balancing procedure, making it accessible for both experienced technicians and new users. Applications span across automotive manufacturing, aerospace components, industrial fan production, and precision machinery sectors.