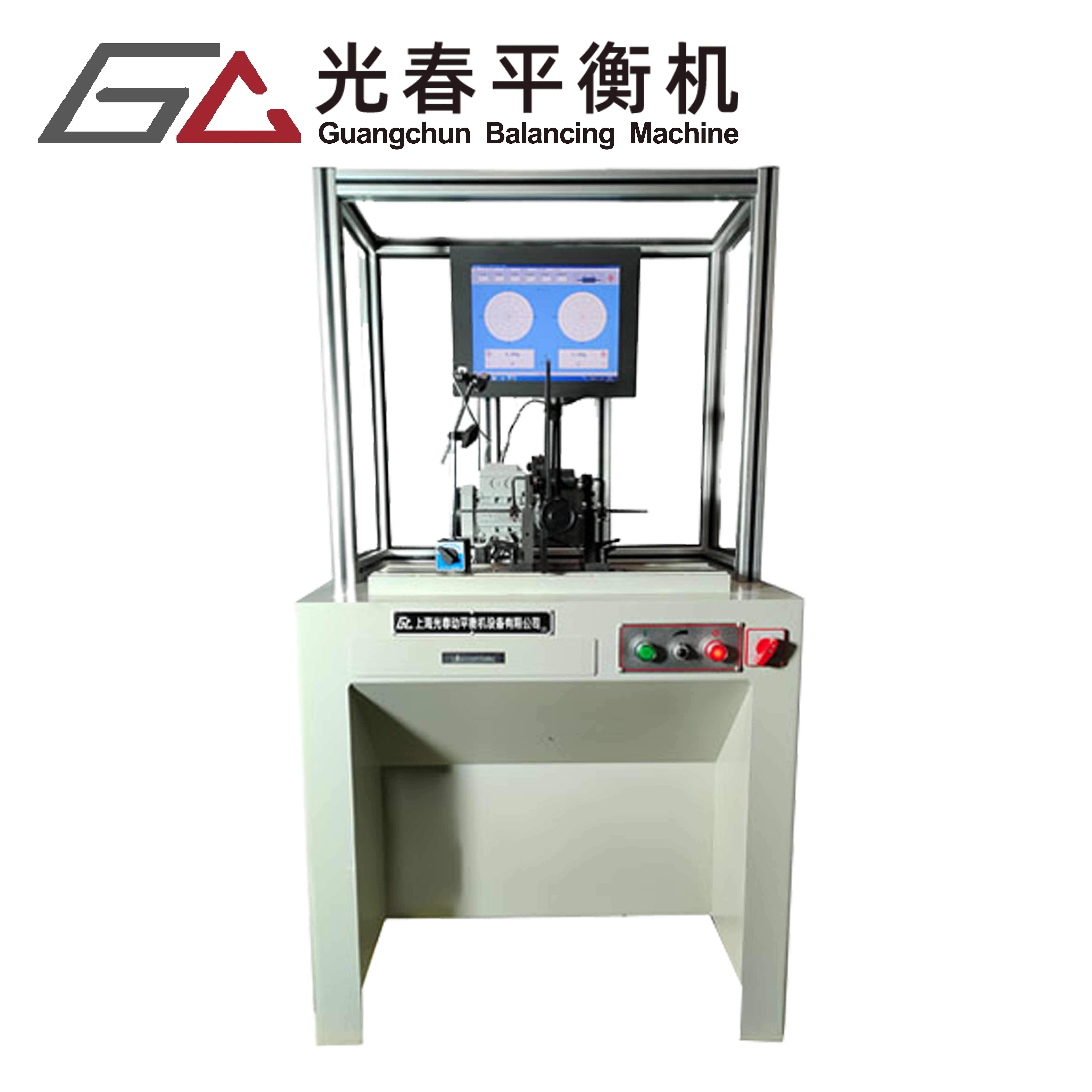

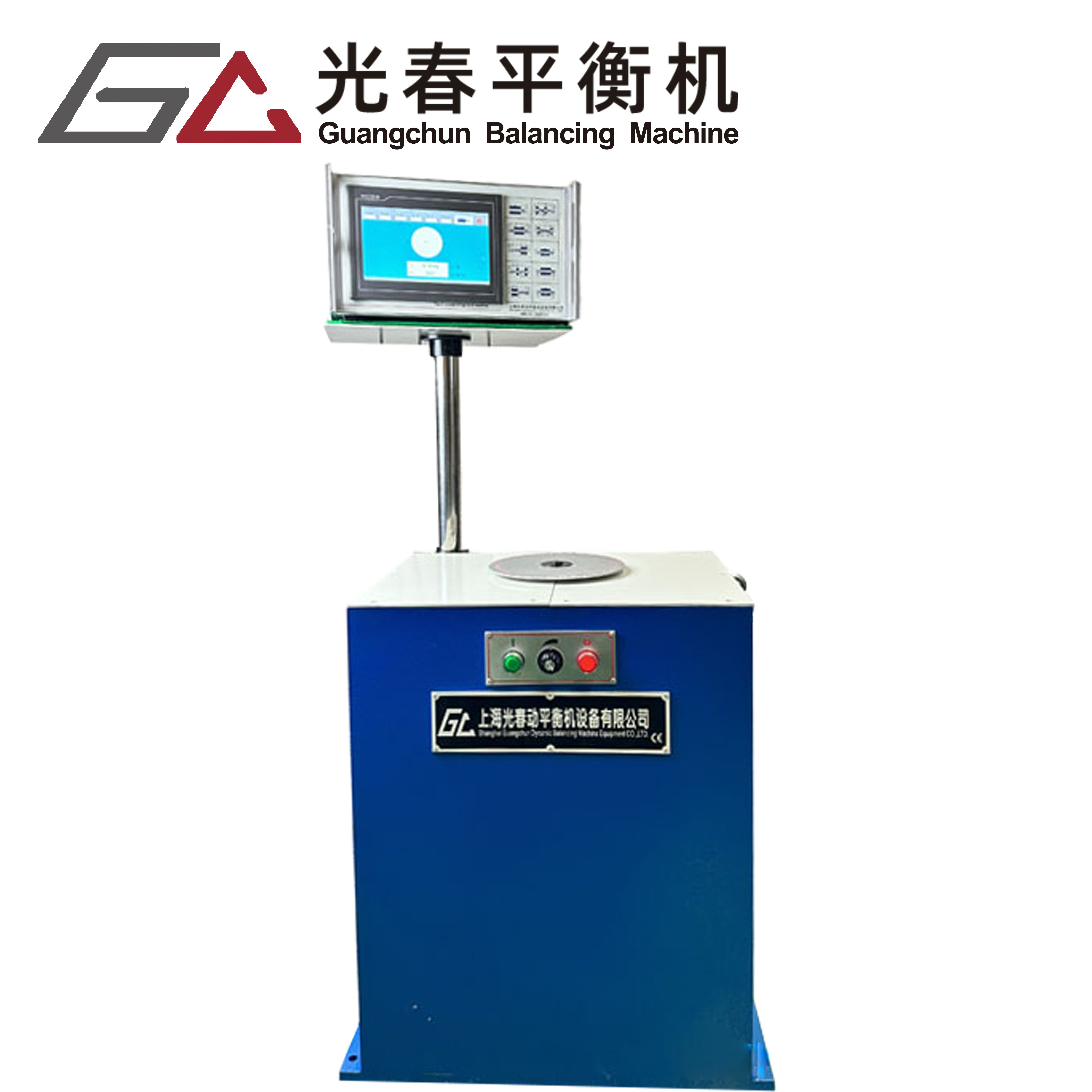

dynamic balancing software

Dynamic balancing software represents a cutting-edge solution for industrial machinery maintenance and optimization. This sophisticated technology enables real-time analysis and correction of rotational imbalances in various mechanical systems, from small turbines to large industrial equipment. The software utilizes advanced algorithms to process data from sensors, providing precise measurements of vibration patterns, rotational speeds, and mass distribution. It offers comprehensive features including automated data collection, real-time monitoring, detailed analysis reports, and correction recommendations. The system can simultaneously track multiple measurement points, creating a complete picture of machine behavior during operation. Key functionalities include spectral analysis, phase measurements, and automated balancing calculations that significantly reduce the time required for balance corrections. The software integrates seamlessly with modern balancing hardware, offering intuitive interfaces that guide users through the balancing process step by step. It supports various industry standards and can handle both single-plane and multi-plane balancing operations. Additionally, the software includes advanced reporting capabilities, allowing users to generate detailed documentation of balancing procedures and results for quality assurance and maintenance records.