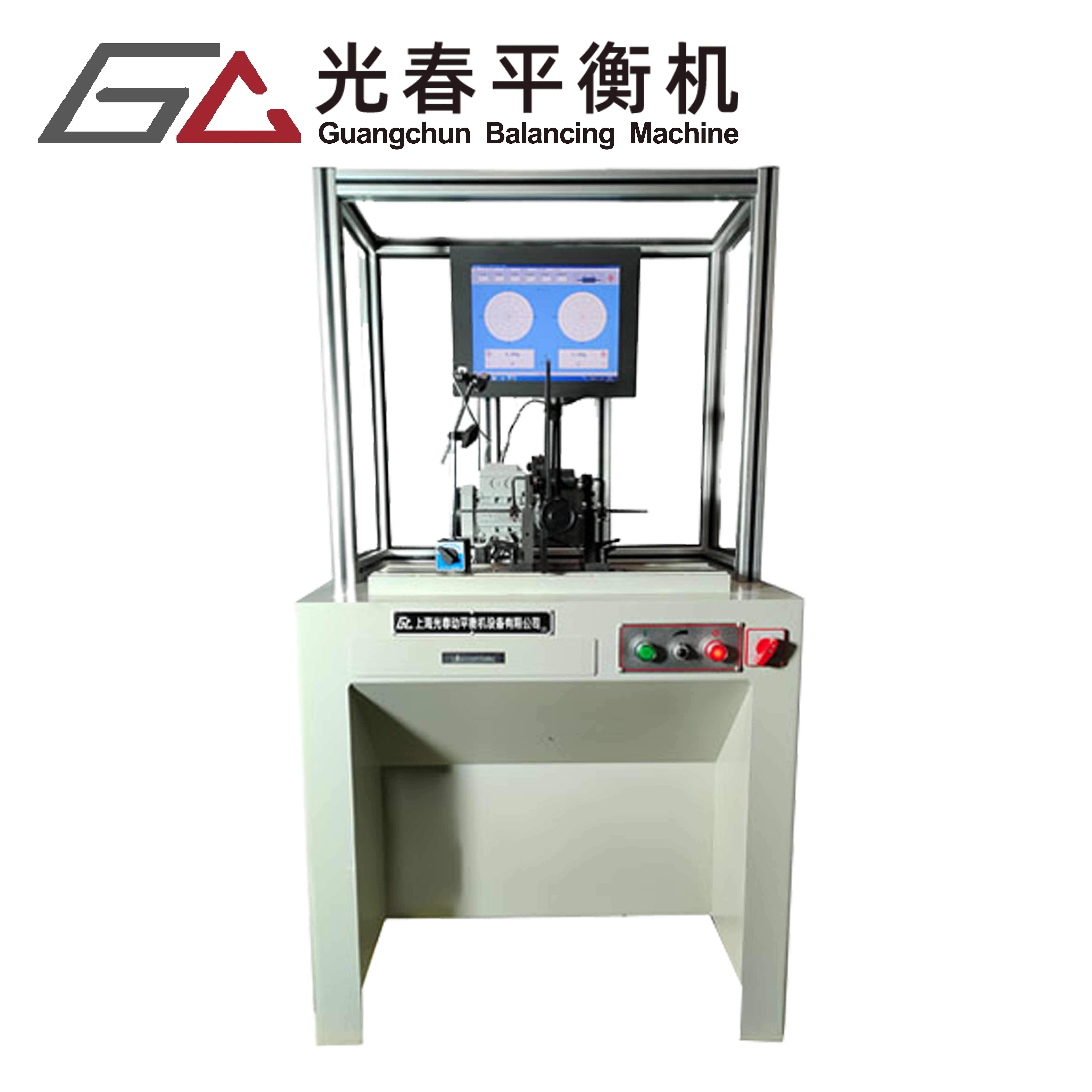

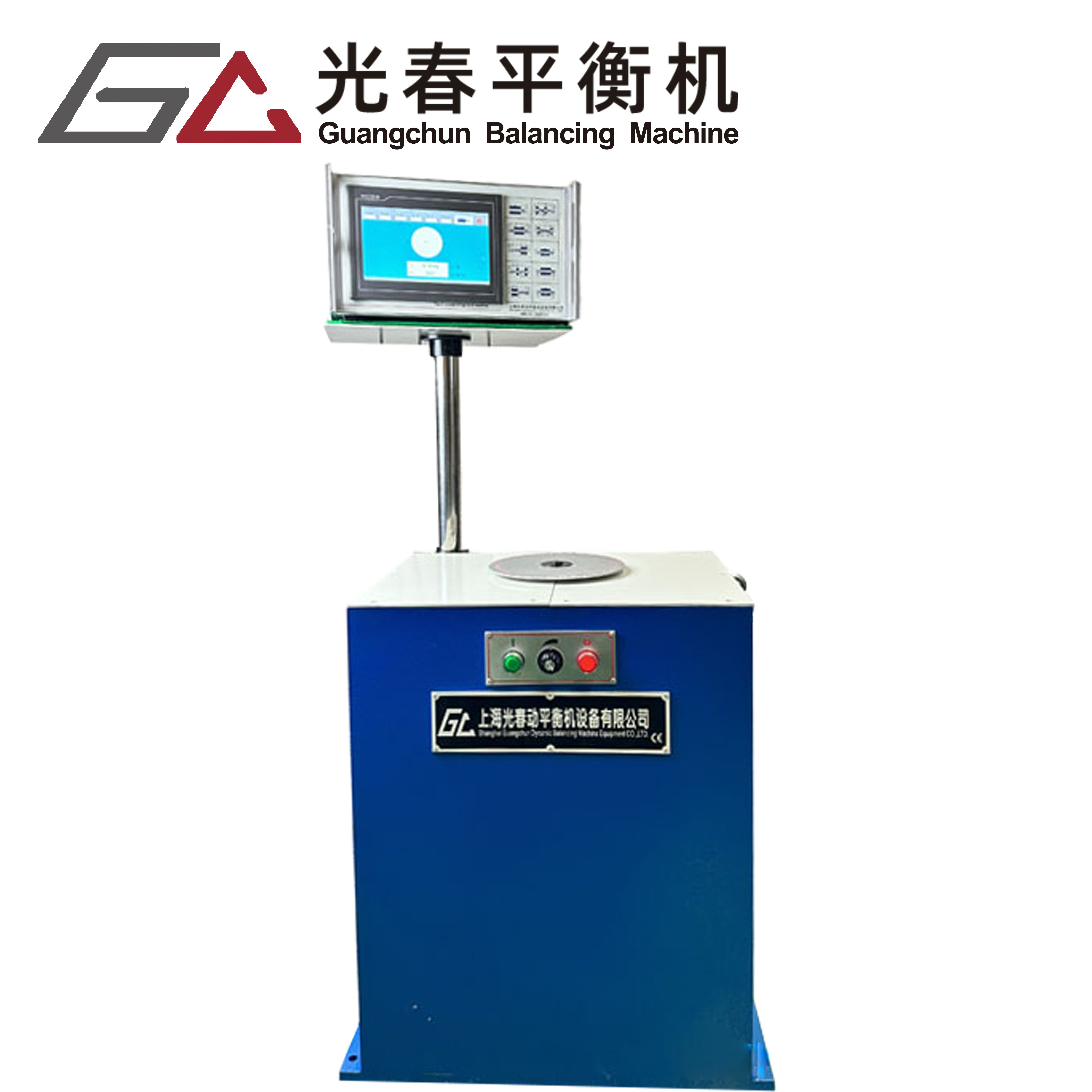

field balancing equipment

Field balancing equipment represents a crucial advancement in modern industrial maintenance technology, designed to diagnose and correct rotational imbalance in machinery while operating in its installed location. This sophisticated equipment combines precision sensors, advanced digital processing capabilities, and user-friendly interfaces to detect, measure, and correct uneven weight distribution in rotating equipment. The system typically consists of portable vibration analyzers, optical or laser tachometers, and specialized software that processes the collected data to determine the exact location and magnitude of imbalance. These tools can measure vibration patterns across multiple planes, providing comprehensive analysis of rotating equipment including fans, turbines, motors, and pumps. The equipment's ability to perform balancing operations without disassembling or removing machinery from its operating position significantly reduces maintenance downtime and associated costs. Modern field balancing systems incorporate real-time monitoring capabilities, allowing technicians to observe immediate results of correction weights placement and make necessary adjustments on the spot. The technology's versatility enables its application across various industrial sectors, from power generation and manufacturing to HVAC systems and marine propulsion.