high quality dynamic balancing

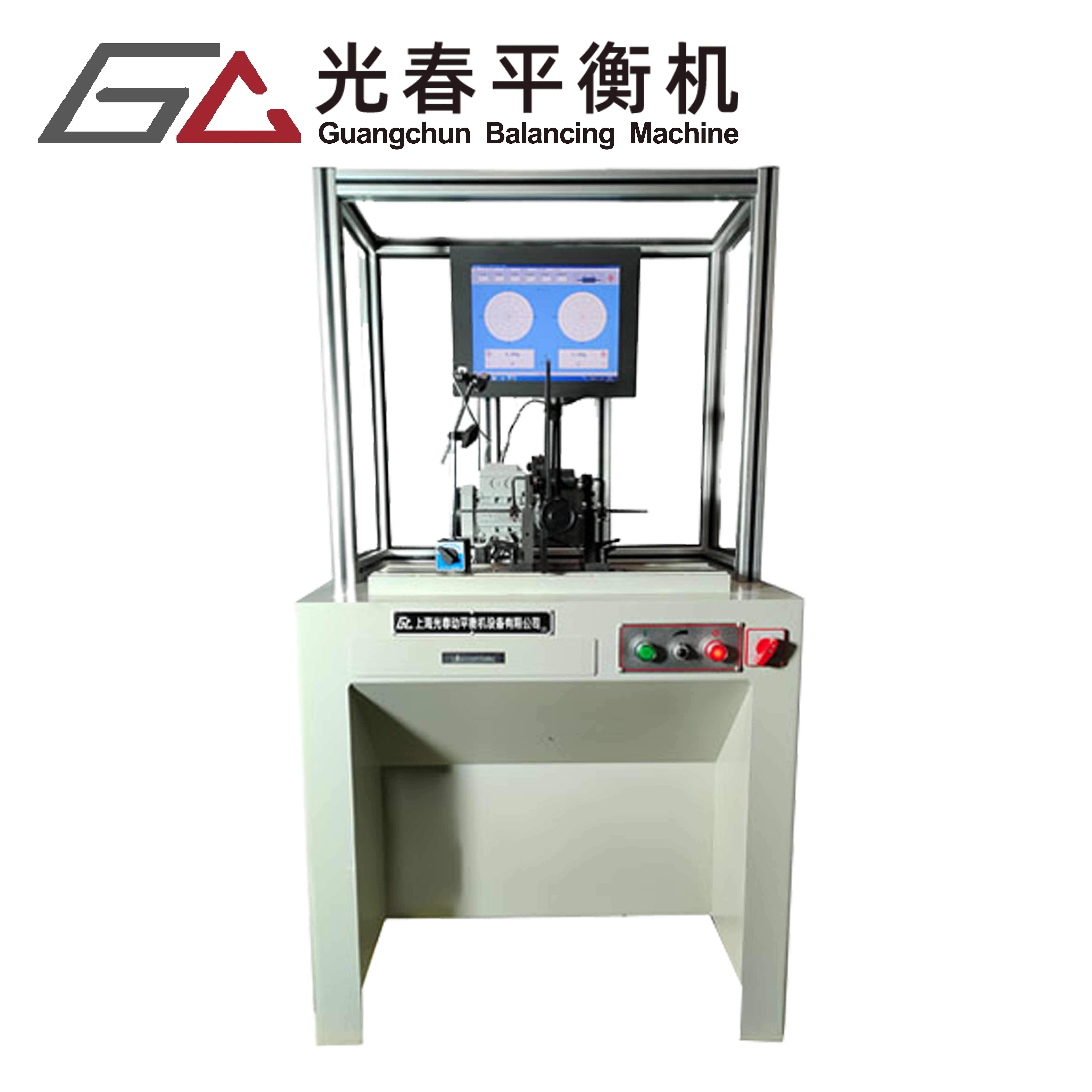

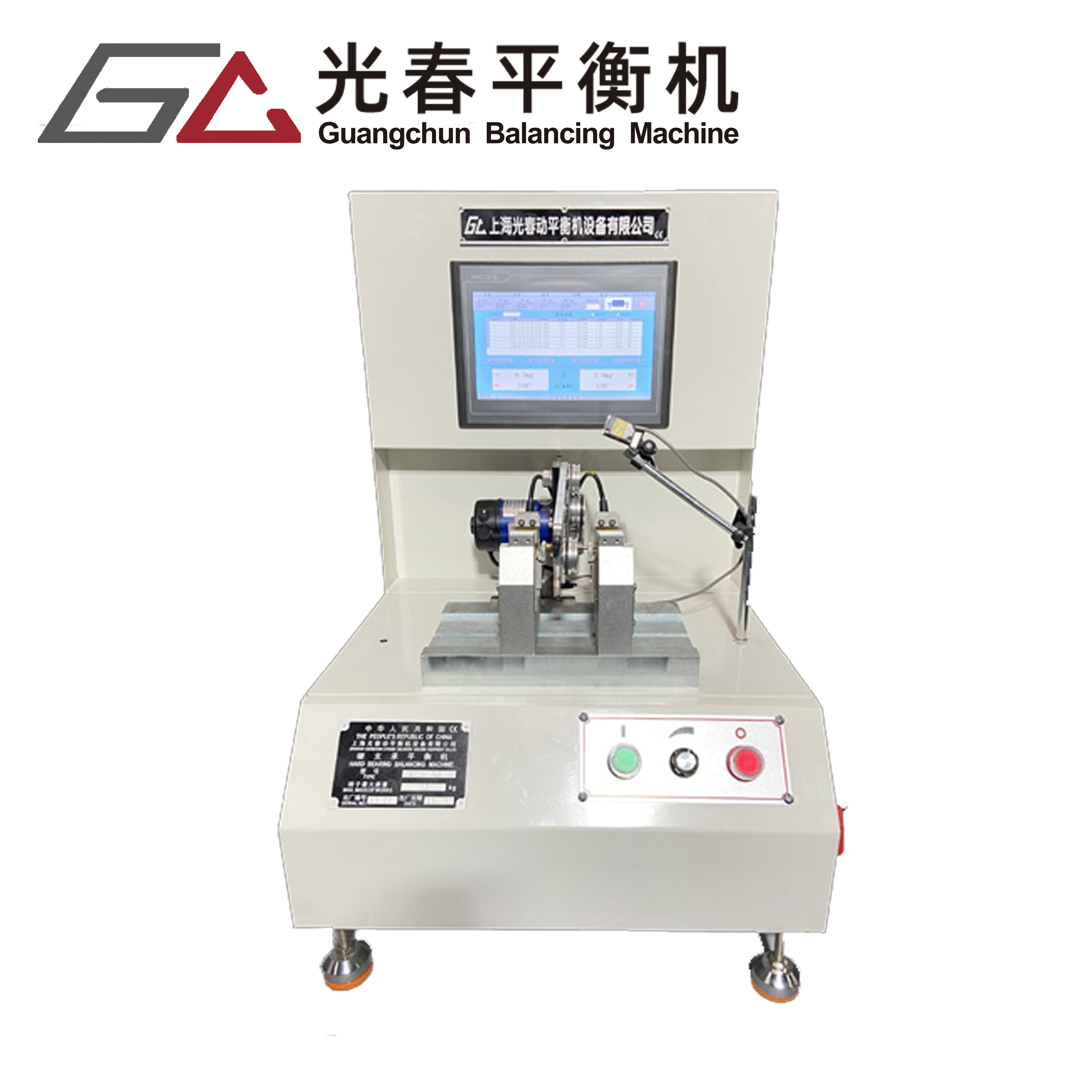

High quality dynamic balancing is a critical process in modern manufacturing and maintenance that ensures rotating equipment operates at peak efficiency and reliability. This sophisticated technique involves the precise measurement and correction of mass distribution in rotating components to eliminate vibration-causing imbalances. The process employs advanced sensors and computerized analysis systems to detect even minimal imbalances at various speeds and operating conditions. The technology utilizes state-of-the-art balancing machines equipped with digital controls and real-time monitoring capabilities, allowing for precise adjustments at both low and high speeds. This process is essential for a wide range of applications, from small precision components like turbine blades to large industrial machinery such as fans, pumps, and motor rotors. The balancing procedure typically involves measuring the amplitude and phase of vibration, calculating the necessary correction weights, and strategically placing these weights to achieve optimal balance. This technology has evolved to incorporate artificial intelligence and machine learning algorithms, enabling predictive maintenance and automated correction recommendations. The result is significantly reduced mechanical stress, extended equipment lifespan, and improved operational efficiency across various industrial applications.