turbocharger repair balancing services

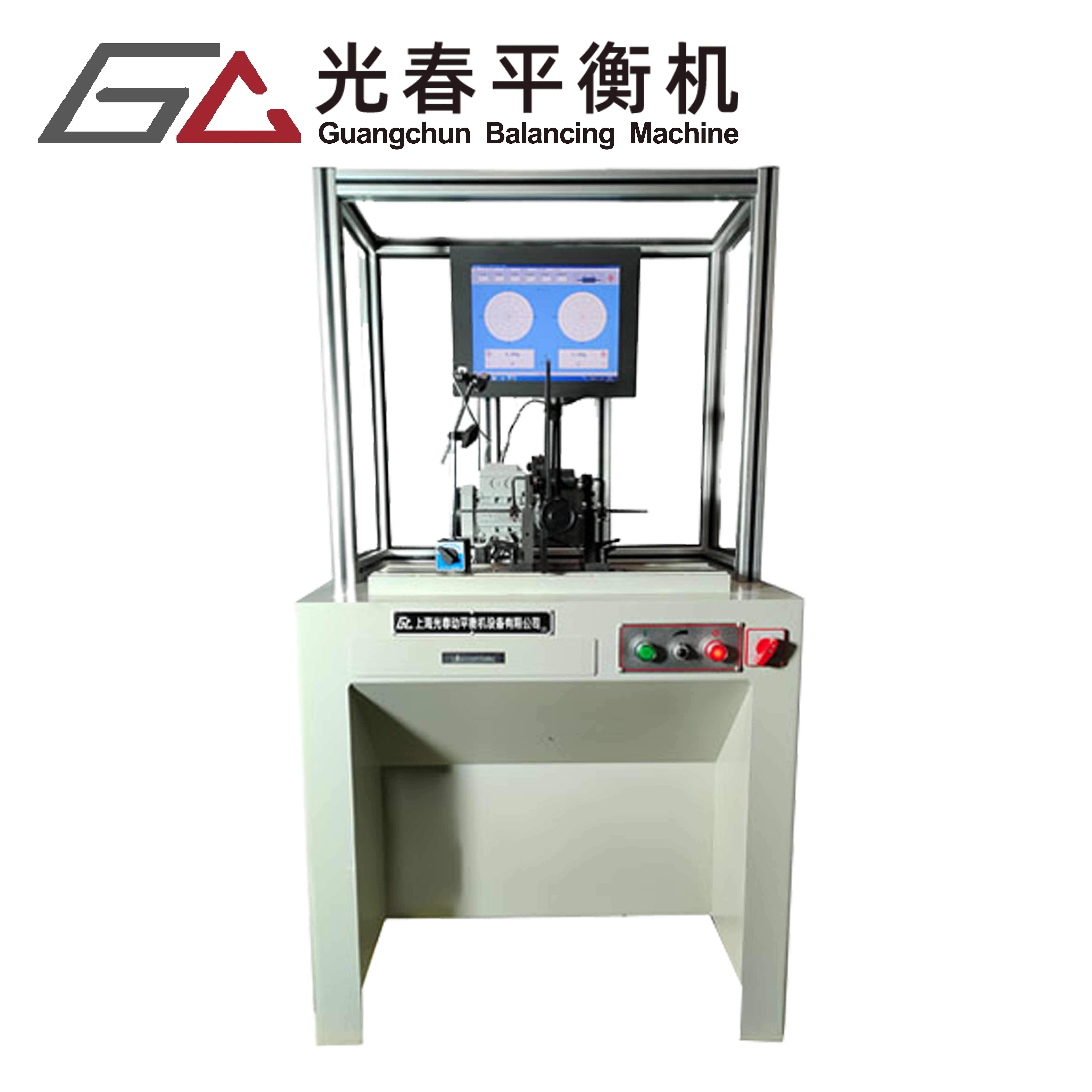

Turbocharger repair balancing services represent a critical maintenance solution for ensuring optimal performance and longevity of turbocharged engines. This specialized service encompasses precision diagnostics, component inspection, and dynamic balancing of turbocharger assemblies at speeds up to 300,000 RPM. Using advanced VSR balancing equipment and computerized analysis tools, technicians meticulously evaluate and correct any imbalances in the turbocharger's rotating assembly, including the turbine wheel, shaft, and compressor wheel. The service addresses various issues such as shaft play, wheel damage, housing wear, and bearing system defects. Technicians perform comprehensive measurements of clearances, runout, and end float to ensure all specifications meet manufacturer standards. The balancing process involves sophisticated vibration analysis to identify potential problems and make necessary adjustments to achieve optimal rotational stability. This service is essential for both automotive and industrial applications, helping to prevent premature failure, reduce noise and vibration, and maintain peak engine efficiency. The process includes thorough cleaning of components, precise assembly procedures, and quality control testing to verify proper operation before reinstallation.