balancing machine motorcycle

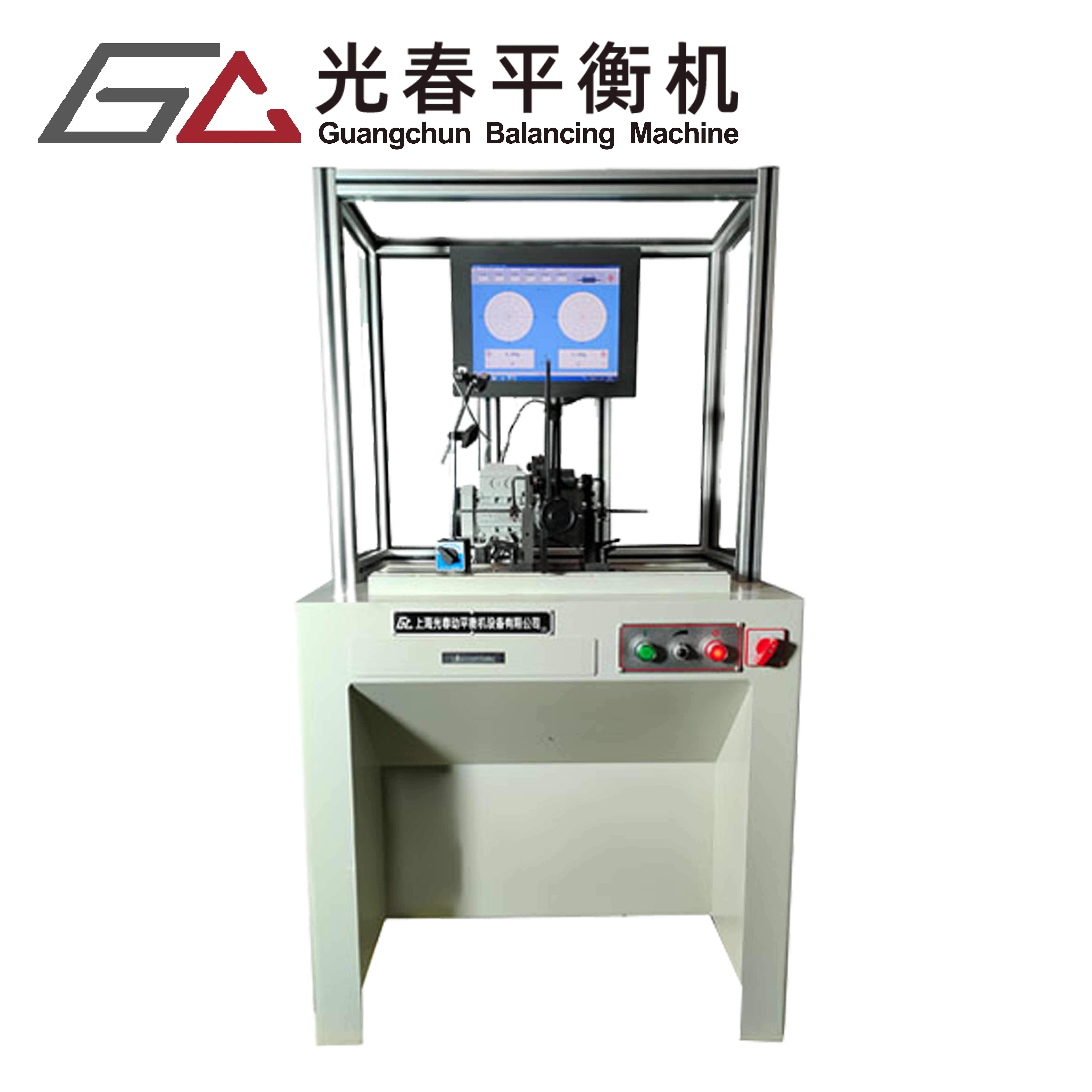

A motorcycle balancing machine is a sophisticated piece of equipment designed to ensure optimal wheel balance and performance in motorcycles. This precision instrument measures and corrects imbalances in motorcycle wheels, tires, and other rotating components, helping to eliminate vibrations that can affect ride quality and safety. The machine operates by spinning the wheel at various speeds to detect any weight inconsistencies that could cause wobbling or instability. Using advanced sensor technology, it precisely identifies the locations where weight needs to be added or removed to achieve perfect balance. The machine typically features a digital display that provides real-time measurements and indicates exactly where to place balancing weights. Modern motorcycle balancing machines often incorporate computerized systems that can detect both static and dynamic imbalances, ensuring comprehensive wheel balancing. These machines are essential tools in motorcycle maintenance shops, manufacturing facilities, and professional racing teams. They can accommodate various wheel sizes and types, from standard street bike wheels to specialized racing components. The technology helps extend tire life, improve handling, and enhance overall riding safety by preventing uneven wear patterns and maintaining proper weight distribution.