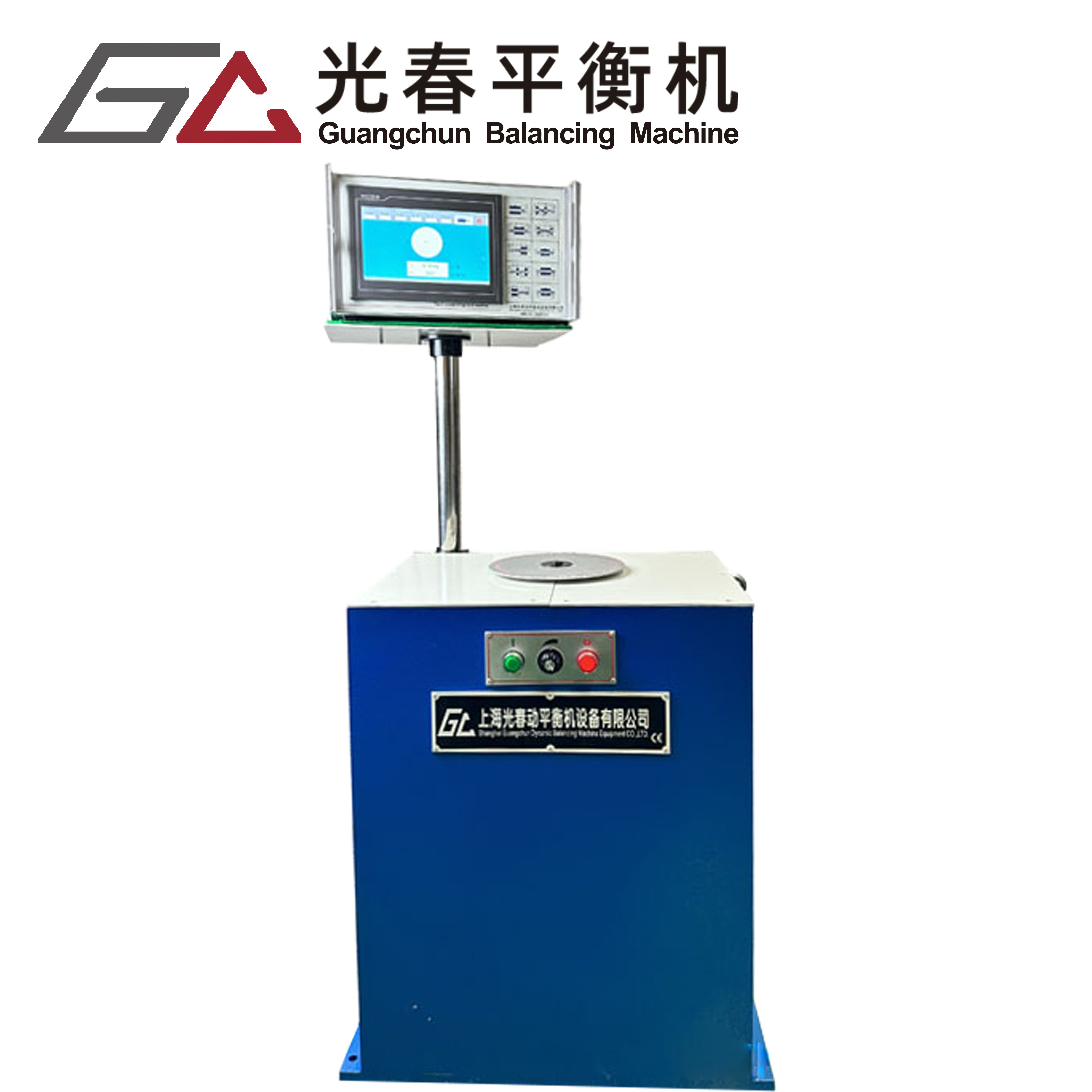

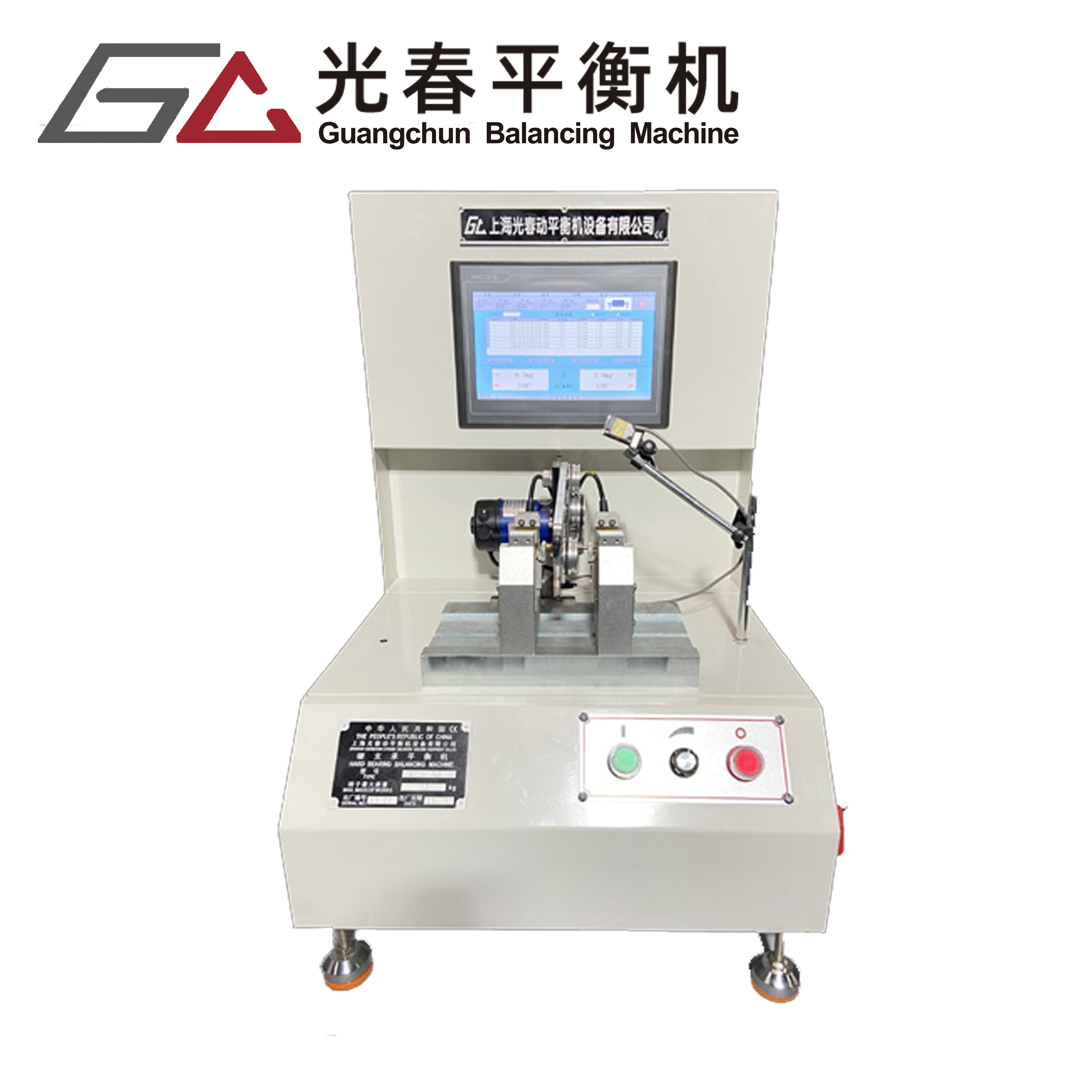

automatic positioning balance machine

The automatic positioning balance machine represents a significant advancement in precision measuring technology, offering unparalleled accuracy and efficiency in balancing operations. This sophisticated equipment combines advanced sensor technology with automated positioning systems to deliver precise measurements and corrections in real-time. The machine automatically detects imbalance in rotating components, calculates the necessary corrections, and determines optimal positions for weight placement or material removal. Operating at speeds of up to 3000 RPM, it can handle workpieces ranging from small precision components to large industrial rotors. The system incorporates multiple measuring planes and intelligent algorithms to analyze both static and dynamic imbalance simultaneously. Its touchscreen interface provides intuitive operation, while the integrated quality control system ensures consistent results across multiple operations. The machine's automatic positioning feature eliminates human error in correction placement, significantly reducing processing time and improving accuracy. It's particularly valuable in industries such as automotive manufacturing, aerospace components, and precision machinery production, where balance quality directly impacts product performance and reliability.