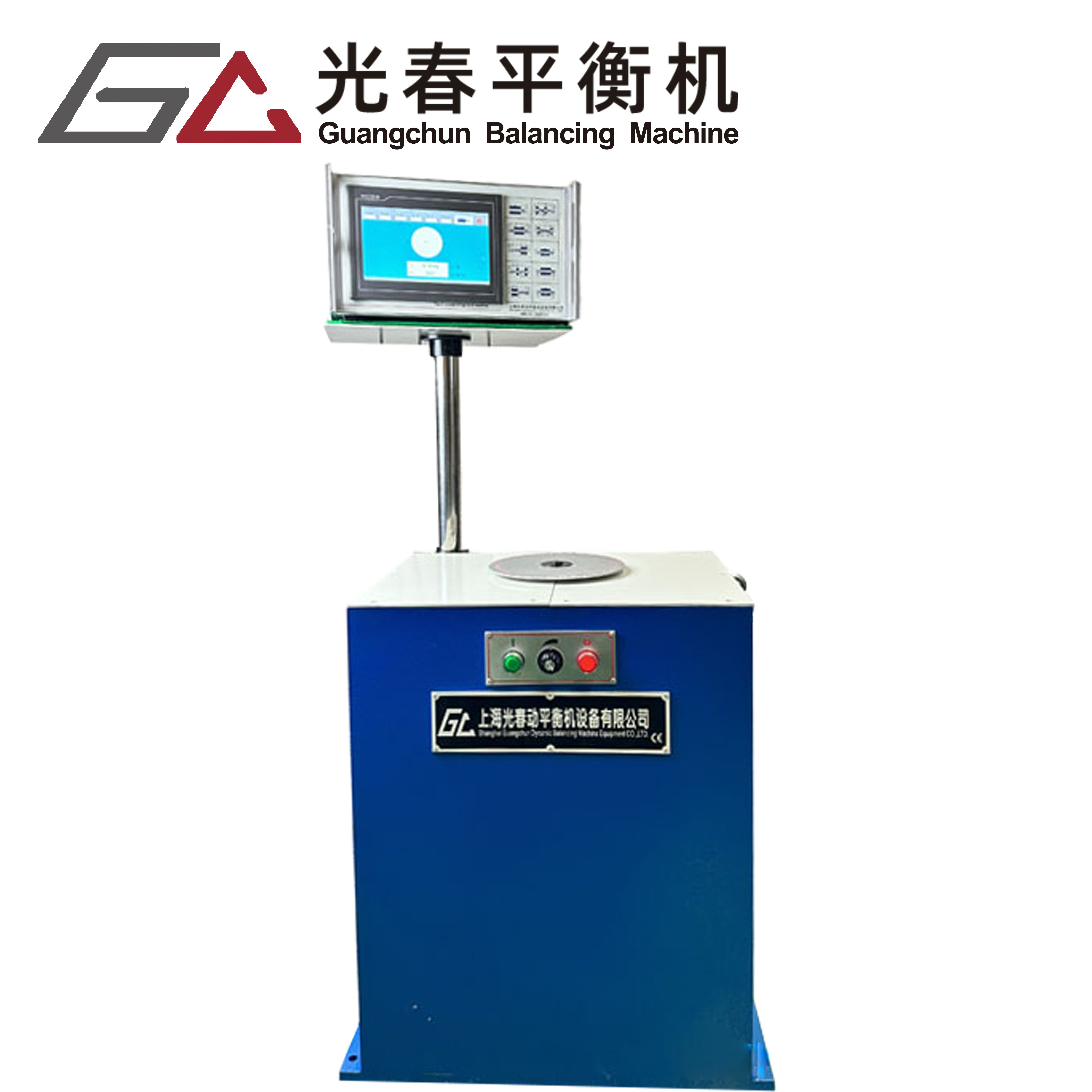

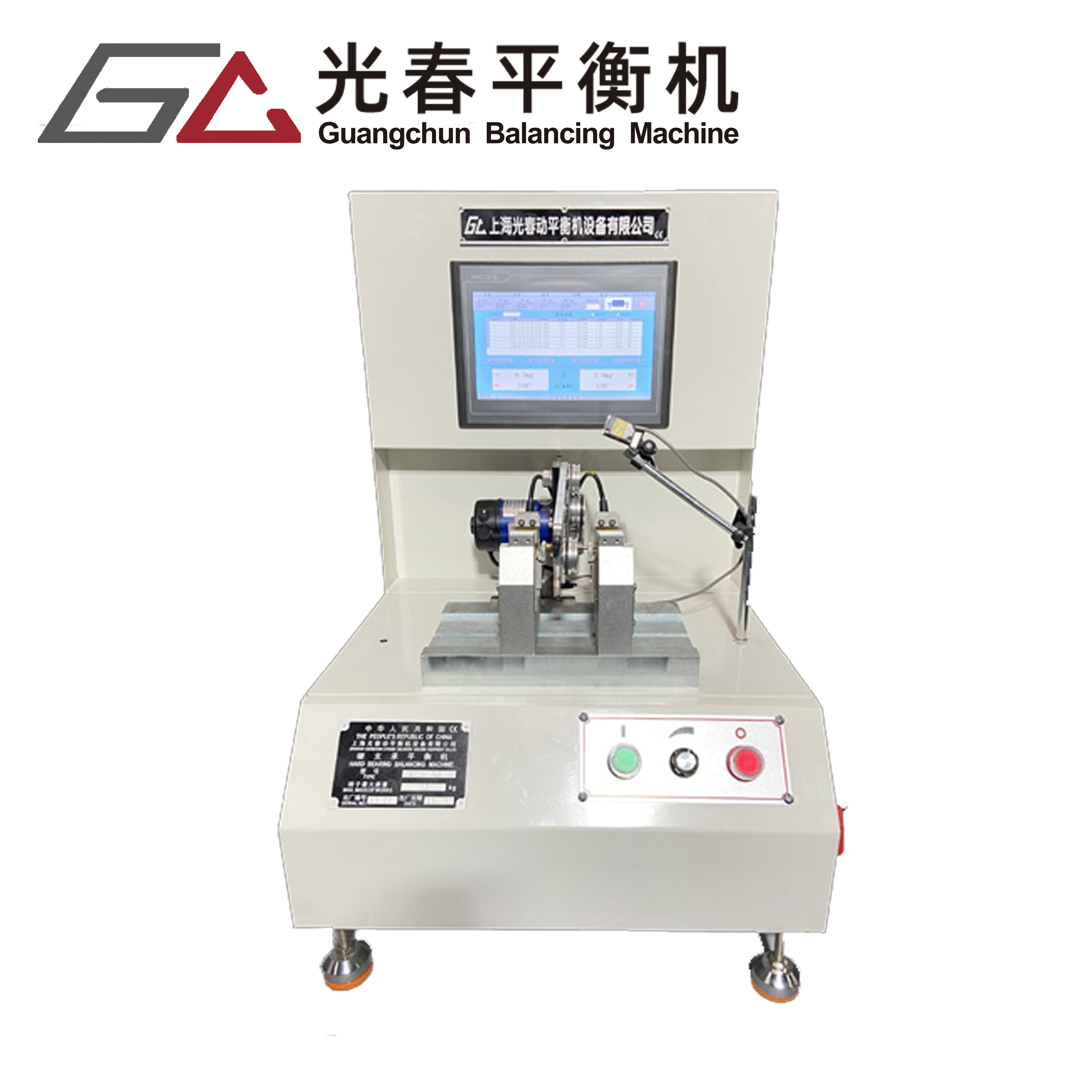

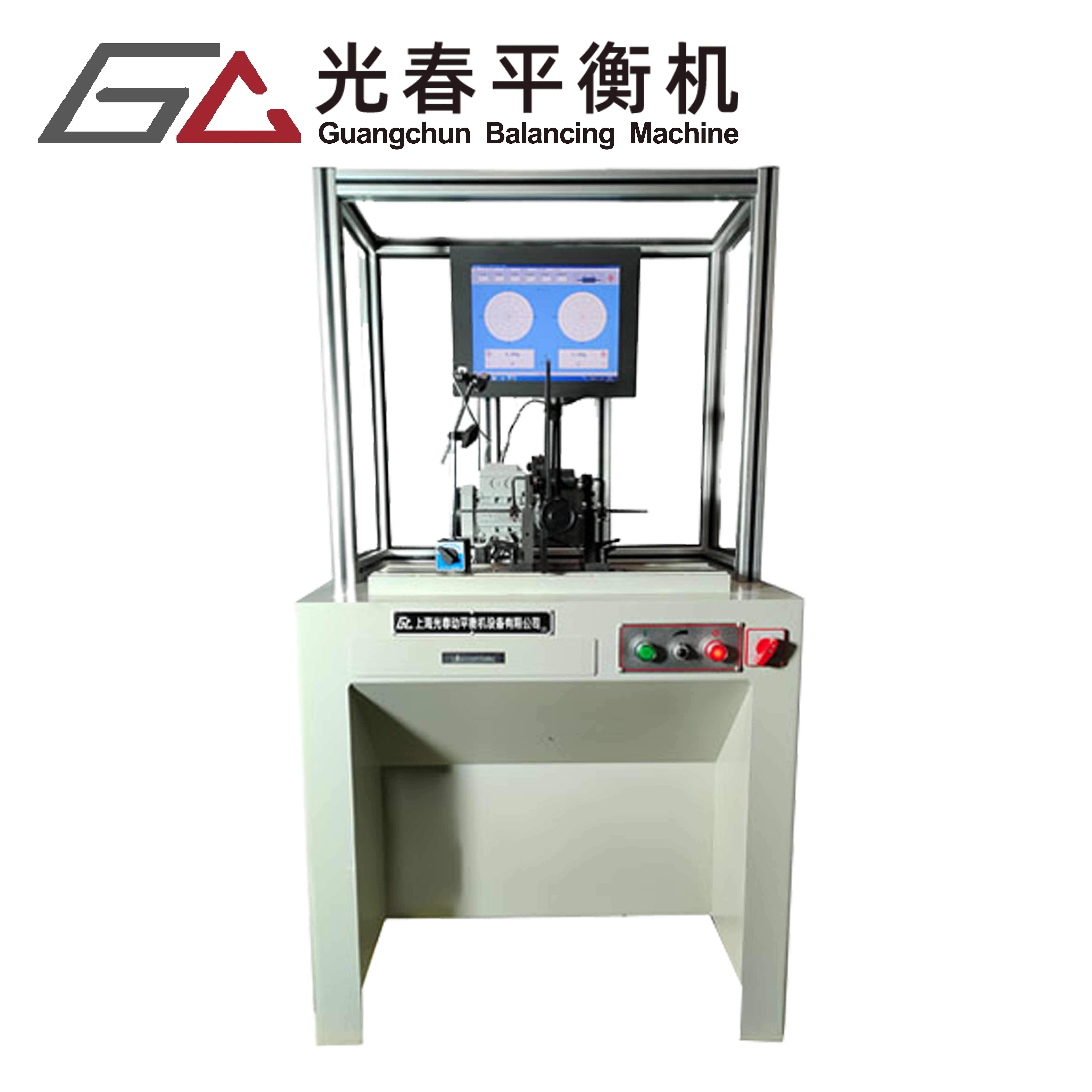

shaft balancing machine

A shaft balancing machine is a sophisticated piece of equipment designed to detect and correct imbalances in rotating components. This precision instrument utilizes advanced sensors and measurement systems to identify even the slightest irregularities in shaft rotation. Operating through a combination of mechanical and electronic systems, the machine measures vibration levels and determines the exact location and magnitude of imbalance. The technology employs high-precision sensors that detect rotational forces and converts them into digital data for analysis. The machine can handle shafts of various sizes and weights, making it versatile for different industrial applications. It features automated measurement cycles that ensure consistent and accurate results, while its digital interface provides real-time feedback and detailed analysis reports. The applications of shaft balancing machines span across multiple industries, including automotive manufacturing, aerospace, power generation, and industrial machinery production. These machines are essential in ensuring the optimal performance of rotating equipment, reducing wear and tear, and preventing premature component failure. The balancing process typically involves mounting the shaft on precision bearings, rotating it at specific speeds, and using sophisticated software to analyze the collected data and determine the necessary corrective measures.