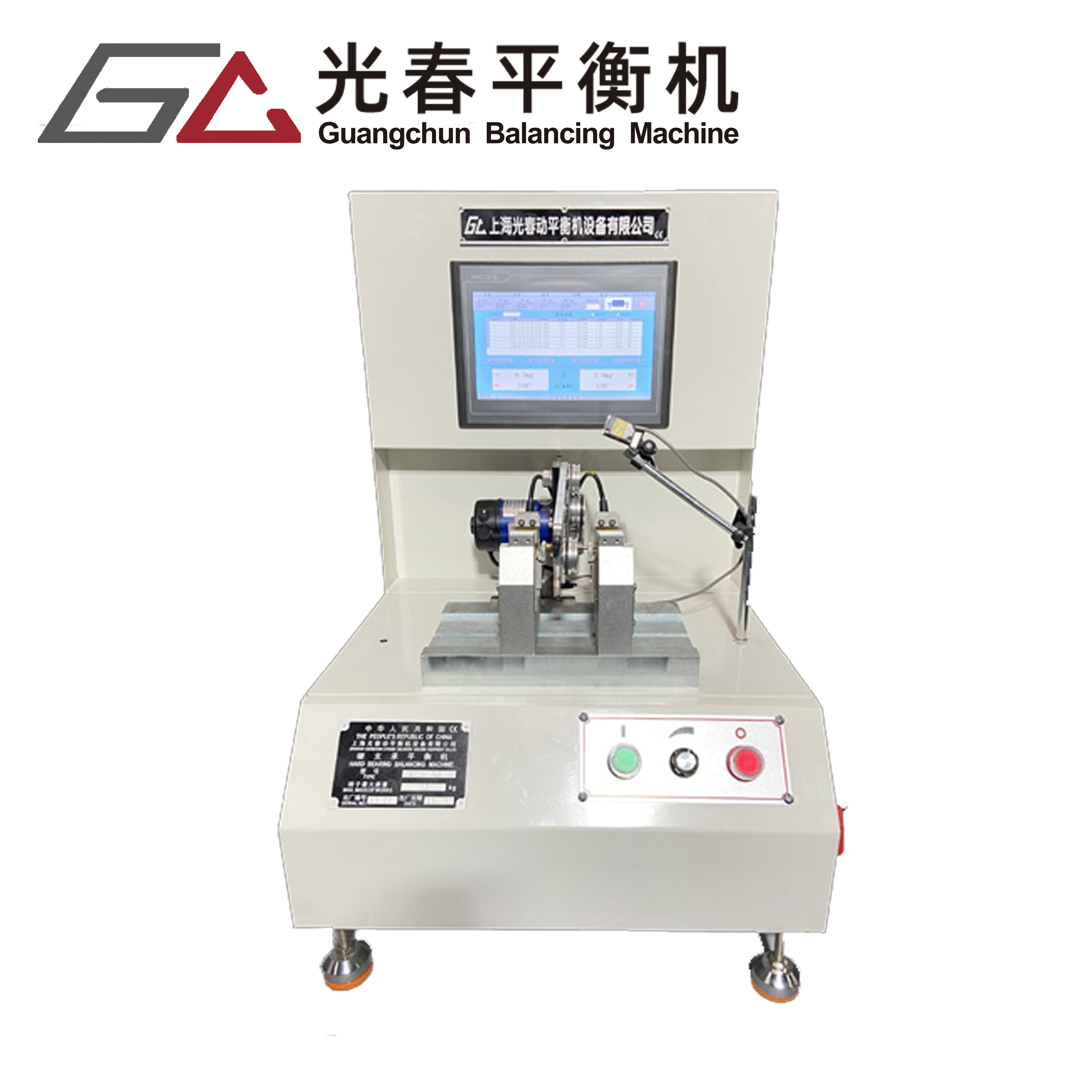

high quality balancing equipment

High quality balancing equipment represents the pinnacle of precision engineering technology, designed to ensure optimal performance across various industrial applications. These sophisticated systems utilize advanced sensors and computational algorithms to detect and correct imbalances in rotating machinery with exceptional accuracy. The equipment combines state-of-the-art mechanical components with intelligent software interfaces, enabling real-time monitoring and adjustment of rotational dynamics. Key features include multiple measurement planes for comprehensive analysis, automated calibration systems for consistent results, and intuitive user interfaces that simplify operation. The equipment can handle components ranging from small precision parts to large industrial rotors, with measuring speeds adaptable from 100 to 100,000 RPM. These systems incorporate vibration analysis capabilities, allowing for detailed diagnostics of imbalance conditions and providing solutions for correction. The technology supports both horizontal and vertical balancing configurations, making it versatile for different manufacturing environments. Built with industrial-grade materials and components, these machines ensure longevity and reliability in demanding production settings, while maintaining precise measuring capabilities within micron-level tolerances.