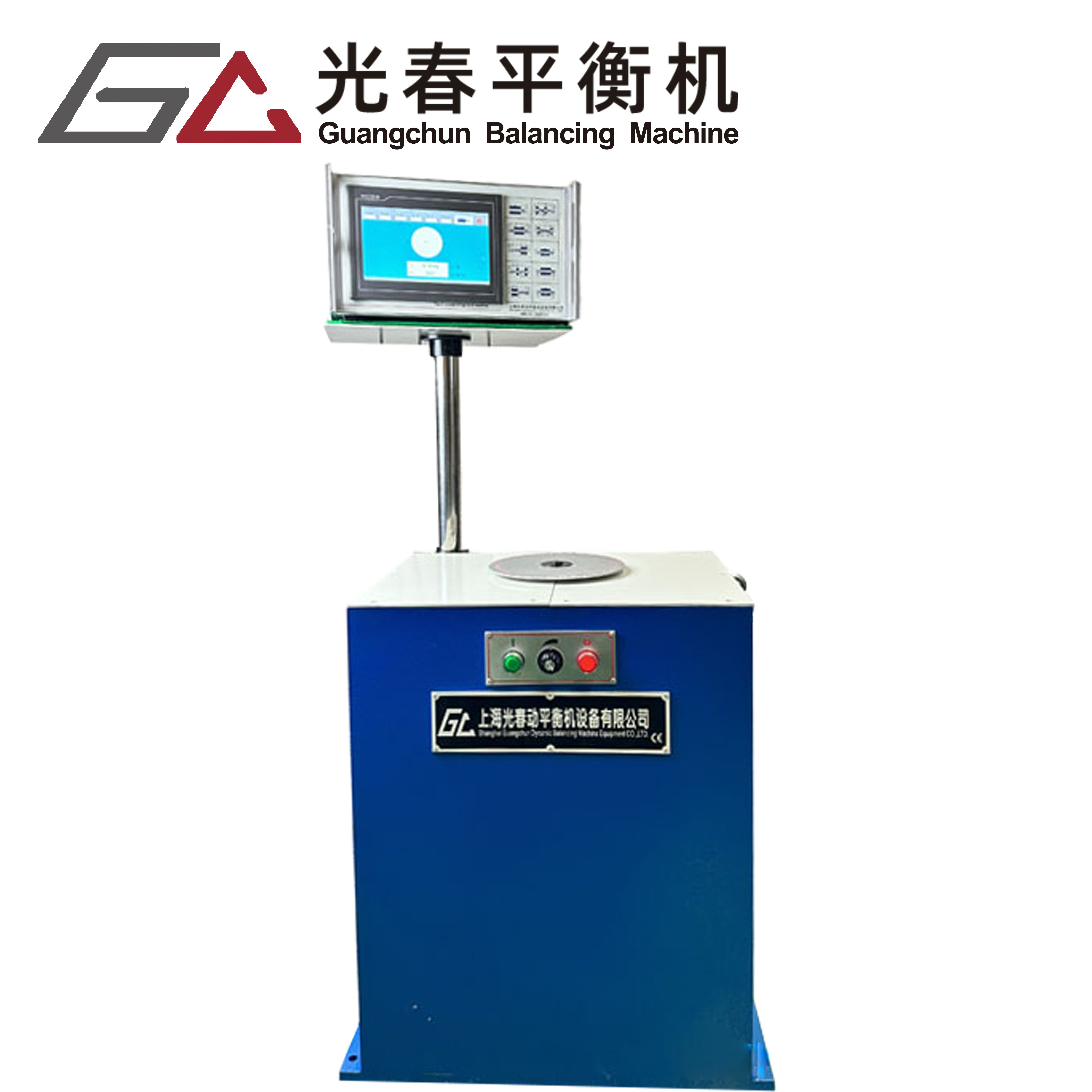

dynamic balancing apparatus

The dynamic balancing apparatus represents a cutting-edge solution in precision engineering, designed to measure and correct rotational imbalances in various mechanical components. This sophisticated system employs advanced sensors and digital processing technology to detect even minute irregularities in rotating parts, ensuring optimal performance and longevity of machinery. At its core, the apparatus consists of a robust support structure, high-precision measurement sensors, and an integrated computer system that processes real-time data. The system can handle components ranging from small turbine blades to large industrial rotors, making it versatile for multiple applications. The apparatus operates by spinning the component at specific speeds while measuring vibration patterns and displacement data. This information is then analyzed through proprietary algorithms to determine the exact location and magnitude of imbalances. What sets this apparatus apart is its ability to perform both static and dynamic balancing procedures, accommodating components of varying sizes and weights with exceptional accuracy. The system's automated calibration and user-friendly interface ensure consistent results while minimizing operator intervention, making it an invaluable tool for manufacturing, maintenance, and quality control operations.