crankshaft grinding and balancing

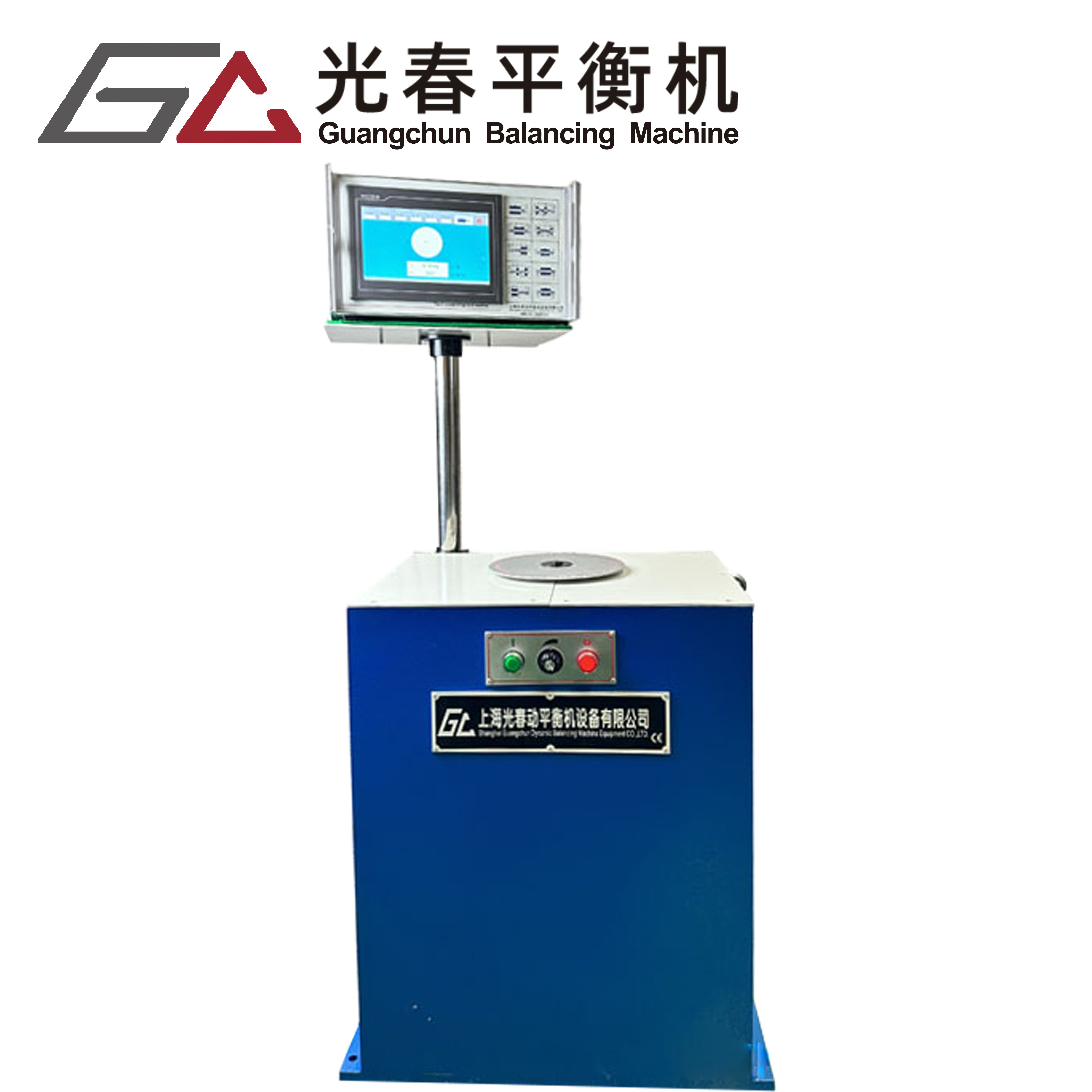

Crankshaft grinding and balancing is a crucial process in engine maintenance and optimization that ensures optimal engine performance and longevity. This precision engineering procedure involves the careful refinement of crankshaft journal surfaces and the establishment of proper weight distribution throughout the rotating assembly. The grinding process utilizes advanced CNC machinery to restore worn journal surfaces to their original specifications, ensuring precise dimensional accuracy down to microns. During the grinding process, specialized equipment removes material from the journals while maintaining critical geometrical relationships and surface finish requirements. The balancing component involves sophisticated electronic equipment that measures and corrects weight disparities in the rotating assembly, eliminating vibrations that could lead to premature wear and reduced performance. This comprehensive process addresses both static and dynamic balance, ensuring smooth operation across all RPM ranges. The technology has evolved to incorporate computer-aided measurement systems and automated grinding processes, allowing for unprecedented accuracy in both material removal and balance correction. These procedures are essential in various applications, from high-performance racing engines to industrial machinery, where precision and reliability are paramount.