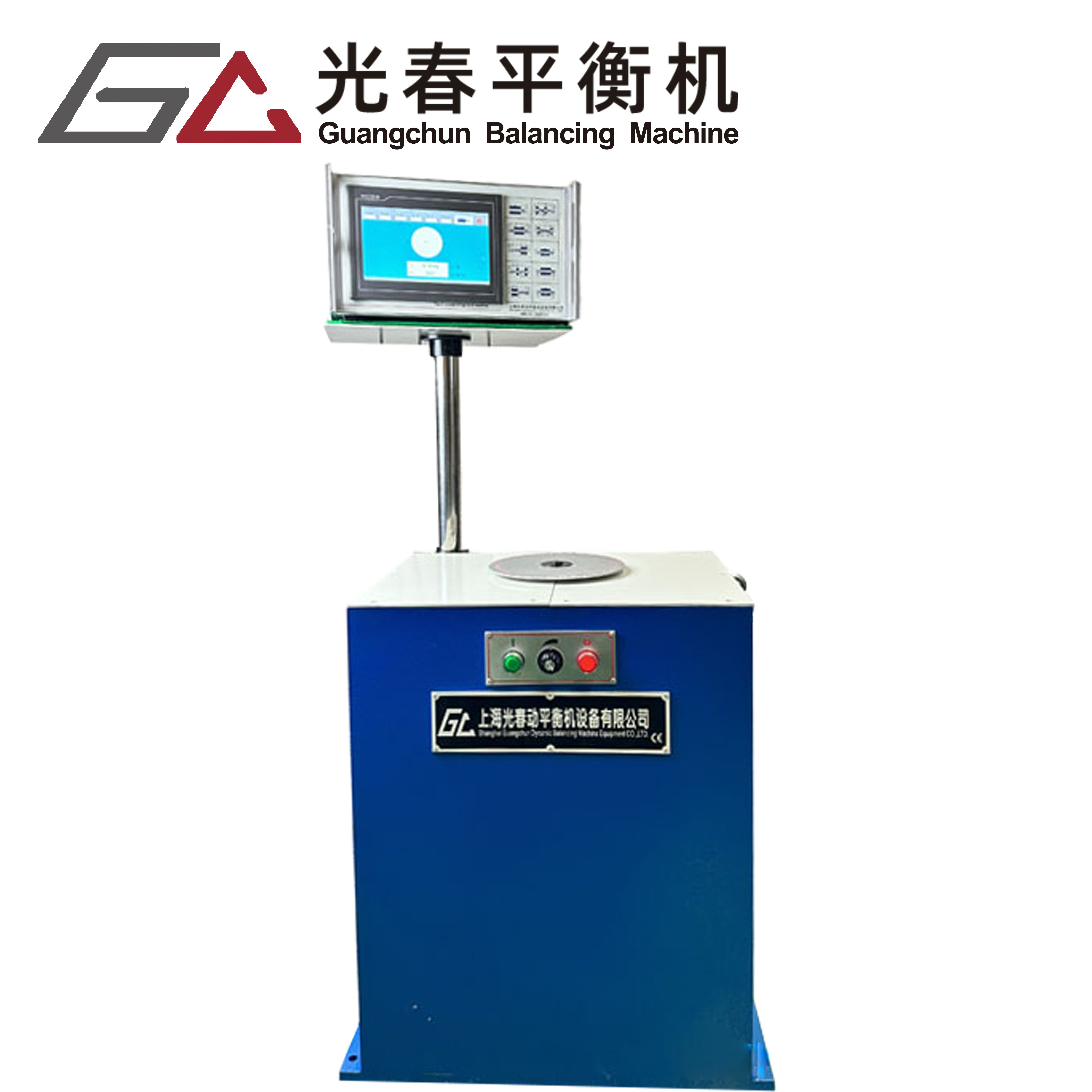

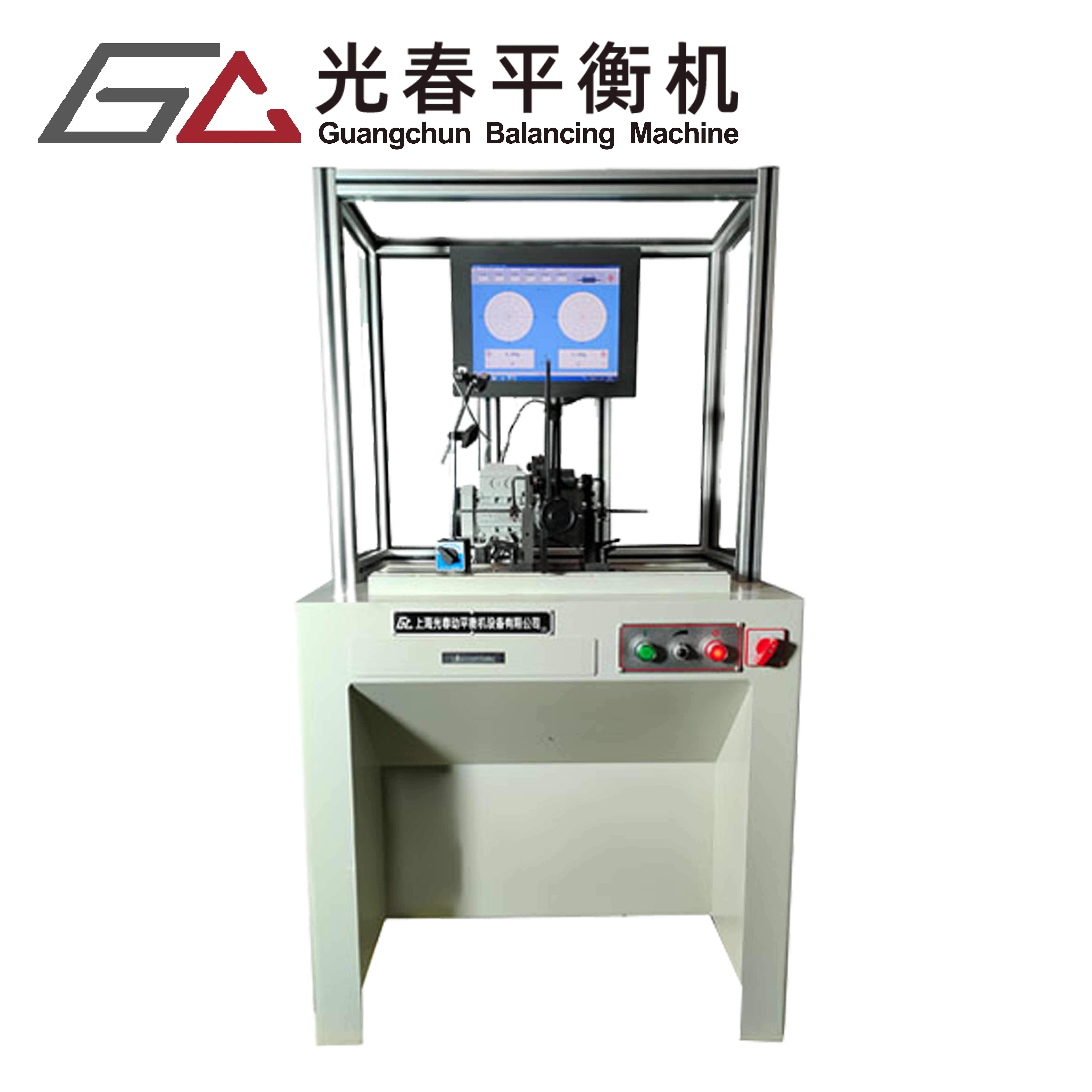

industrial fan balancing equipment

Industrial fan balancing equipment represents a crucial advancement in maintaining optimal performance and longevity of industrial fan systems. This sophisticated machinery utilizes precision sensors and advanced diagnostic tools to detect and correct imbalances in rotating fan components. The equipment typically consists of portable analyzers, vibration sensors, balancing software, and specialized tools for weight placement. These systems can perform both single-plane and dual-plane balancing operations, accommodating fans of various sizes and configurations. The technology employs real-time monitoring capabilities to measure vibration levels, rotation speed, and phase angles, providing accurate data for precise balance corrections. Modern industrial fan balancing equipment features digital displays, automated calculation systems, and user-friendly interfaces that simplify the balancing process. The equipment can handle fans operating at different speeds and loads, making it versatile for various industrial applications including HVAC systems, power plants, manufacturing facilities, and processing plants. Additionally, these systems often include data logging capabilities for tracking historical performance and maintaining detailed maintenance records.