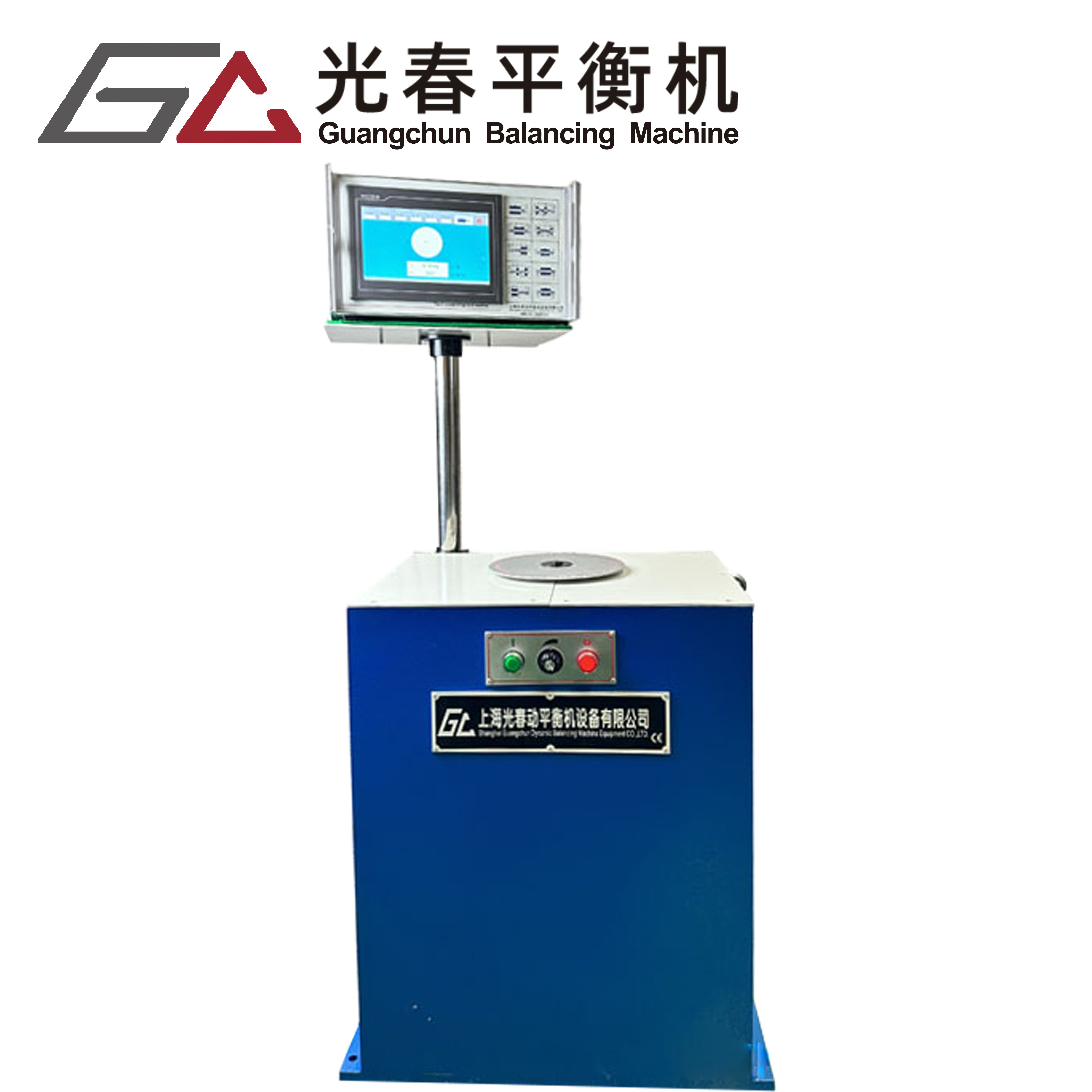

engine balancing machine

An engine balancing machine is a sophisticated piece of equipment designed to ensure optimal performance and longevity of engine components. This precision instrument measures and corrects imbalances in rotating engine parts, such as crankshafts, flywheels, and connecting rods. The machine operates by mounting the component on specialized supports and rotating it at specific speeds to detect any weight disparities or irregularities. Using advanced sensors and computer-aided measurement systems, it identifies the exact locations and magnitudes of imbalances with microscopic precision. The technology employs both static and dynamic balancing methods, allowing for comprehensive analysis of both stationary and rotating imbalances. Modern engine balancing machines feature digital interfaces that provide real-time data analysis and automated correction recommendations. These machines can handle components of various sizes and weights, from small motorcycle engines to large industrial power plant components. The balancing process is crucial in preventing vibration, reducing wear and tear, extending engine life, and ensuring smooth operation across all RPM ranges. This technology has become indispensable in automotive manufacturing, engine rebuilding, and precision engineering industries, where even minimal imbalances can lead to significant performance issues and mechanical failures.