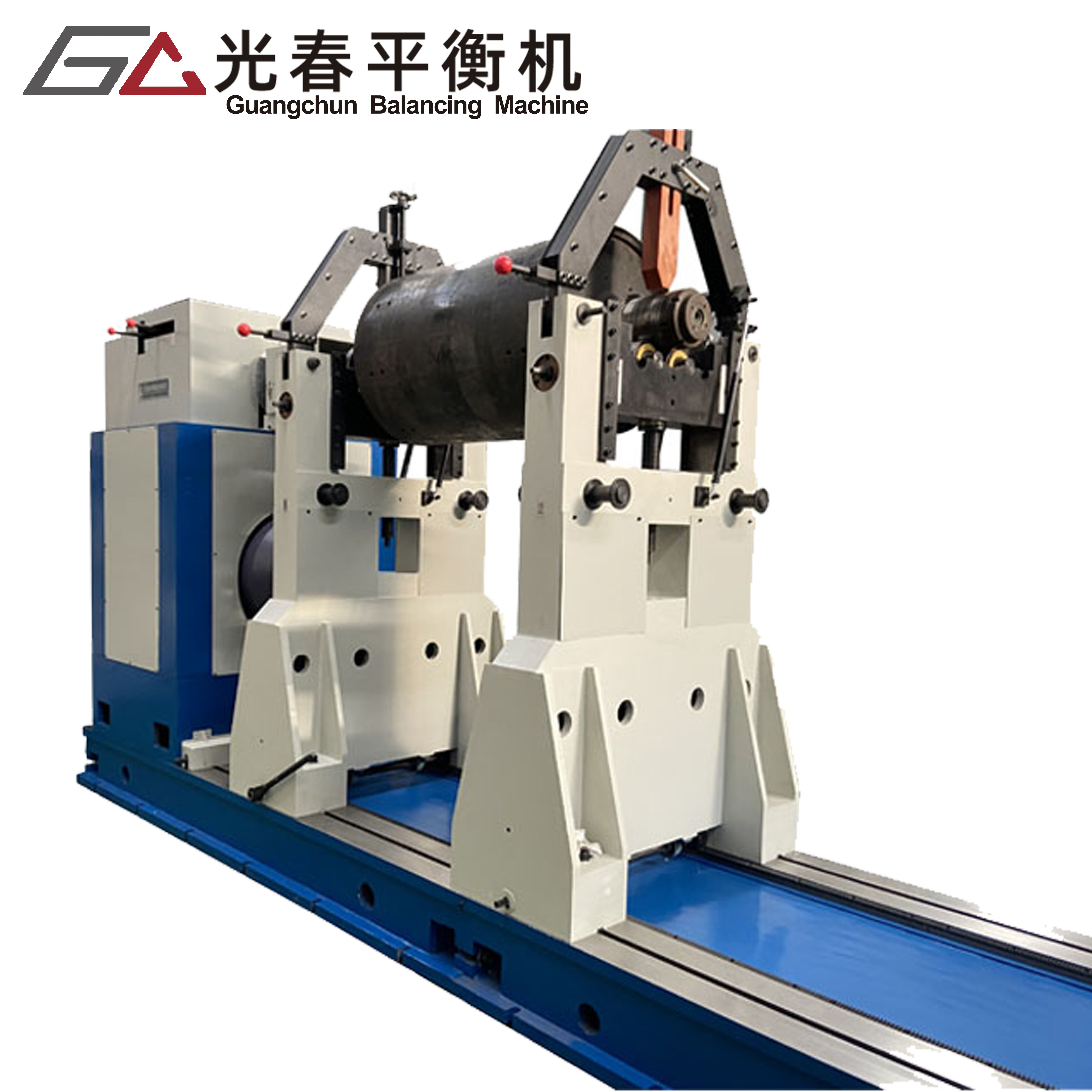

flywheel balancing for marine engines

Flywheel balancing for marine engines is a critical maintenance procedure that ensures optimal engine performance and longevity in maritime applications. This precise engineering process involves the careful adjustment of weight distribution within the flywheel to eliminate vibrations and ensure smooth engine operation. The flywheel, serving as a mechanical energy storage device, plays a vital role in maintaining consistent engine speed and power delivery. Modern flywheel balancing techniques utilize advanced electronic equipment to detect even minimal imbalances, measuring to within fractions of a gram. This technology enables technicians to identify exact locations where weight adjustments are needed. The process typically involves both static and dynamic balancing methods, ensuring the flywheel rotates perfectly around its axis at all operational speeds. In marine applications, properly balanced flywheels are particularly crucial due to the harsh operating conditions at sea, where any imbalance can lead to increased wear, reduced efficiency, and potential mechanical failures. The procedure also encompasses comprehensive inspection of the flywheel for signs of wear, cracks, or other damage that could compromise its integrity. Professional marine engine flywheel balancing services often include detailed documentation of the balancing process, including before and after measurements, ensuring compliance with maritime safety standards and regulations.