flywheel balancing machine

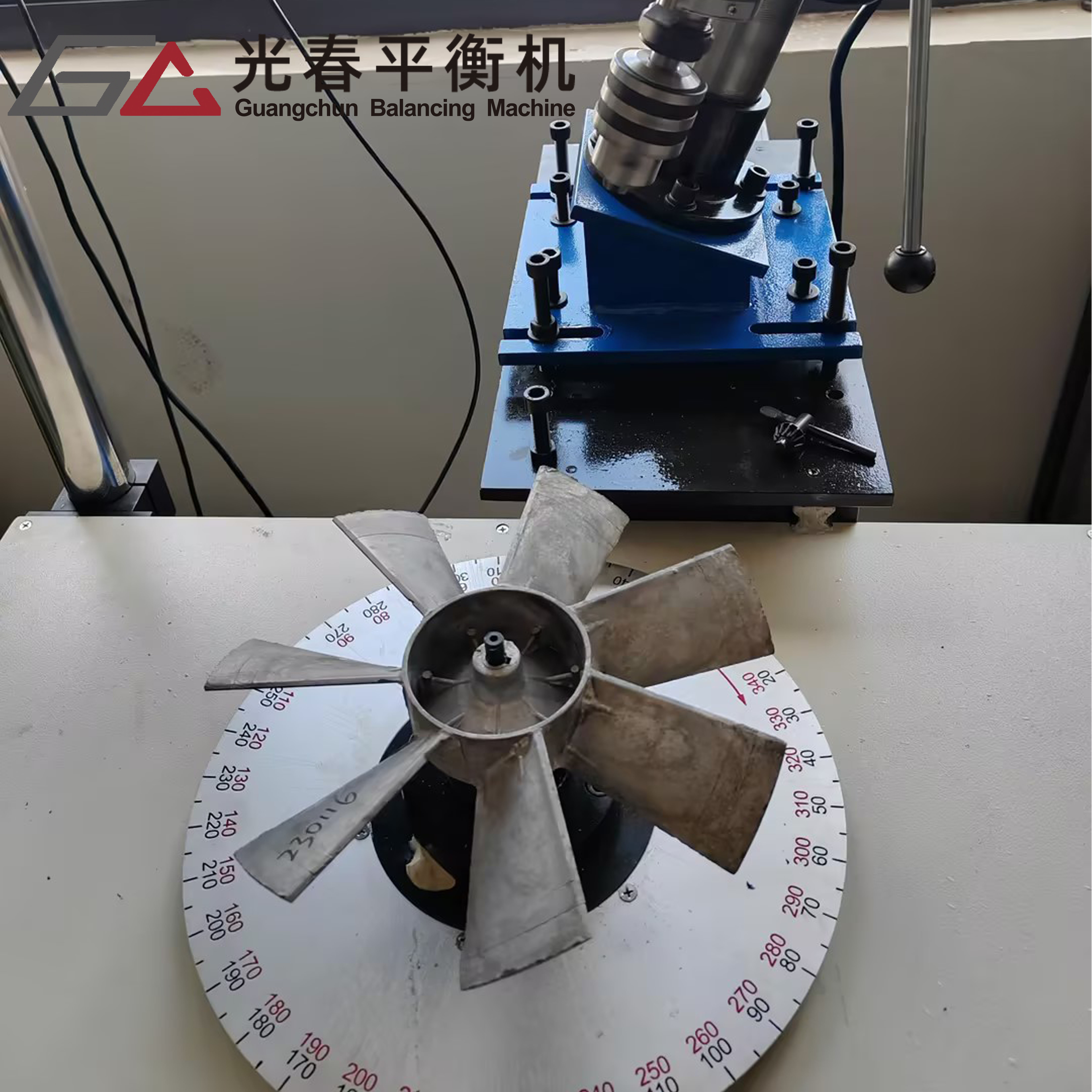

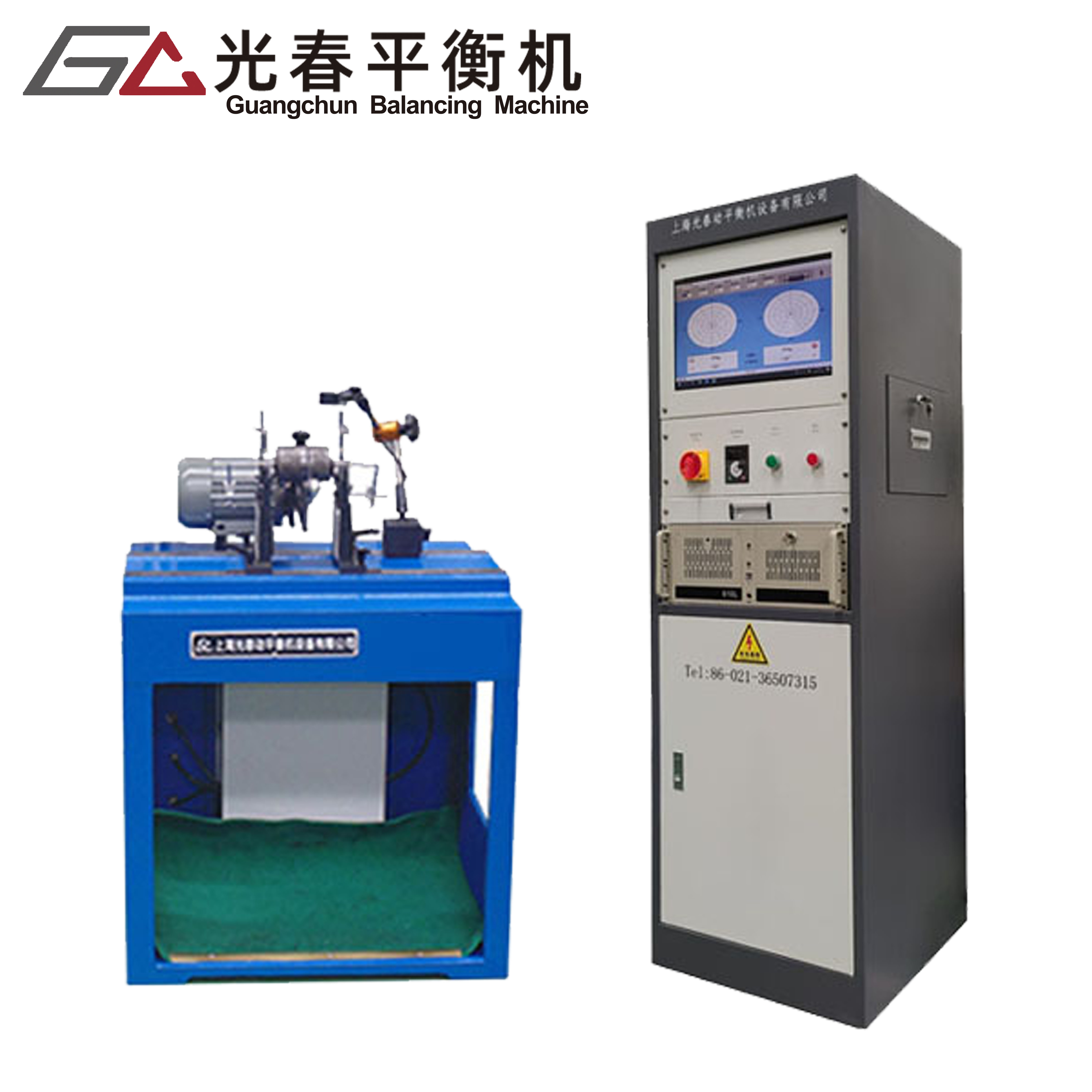

A flywheel balancing machine is a sophisticated piece of equipment designed to detect and correct imbalances in flywheels, crucial components in various mechanical systems. This precision instrument utilizes advanced sensing technology to measure both static and dynamic imbalances that could potentially cause vibration, wear, and reduced performance in machinery. The machine operates by mounting the flywheel on a specialized spindle and rotating it at specific speeds while sensitive sensors detect any irregularities in the rotation. These sensors measure forces and movements in multiple planes, providing detailed data about the location and magnitude of imbalances. The technology incorporates computerized analysis systems that process this data in real-time, offering precise measurements down to fractions of a gram. Modern flywheel balancing machines feature user-friendly interfaces that display detailed graphical representations of imbalance locations and recommended correction methods. They are widely used in automotive manufacturing, heavy machinery production, and aerospace industries where precision balancing is critical for optimal performance and safety. The machines can accommodate flywheels of various sizes and weights, making them versatile tools for different industrial applications.