motorized spindle balance machine

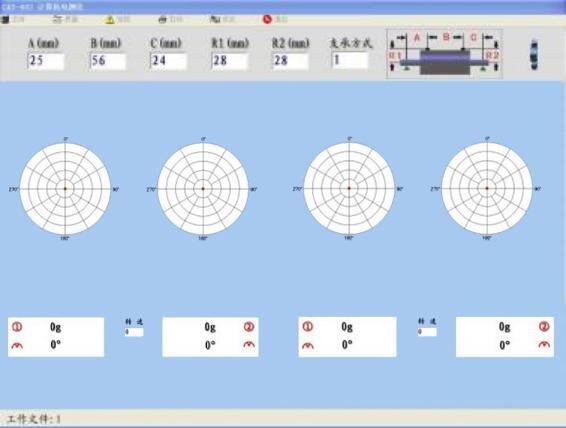

A motorized spindle balance machine represents a cutting-edge solution in precision engineering, designed to achieve optimal rotational balance in high-speed spindles and rotating components. This sophisticated equipment utilizes advanced sensor technology and motorized mechanisms to detect and correct imbalances in rotating parts with exceptional accuracy. The machine operates by mounting the spindle onto a specialized testing platform that can rotate at various speeds, typically ranging from 300 to 30,000 RPM, allowing for comprehensive analysis across different operational conditions. Through integrated sensors and digital processing systems, it measures vibration patterns and calculates precise correction weights and positions. The technology incorporates real-time monitoring capabilities, enabling continuous assessment of balance conditions throughout the testing process. Applications span across numerous industries, including CNC machining, aerospace manufacturing, automotive production, and precision tooling. The machine's capability to handle various spindle sizes and weights makes it invaluable for both maintenance operations and new spindle manufacturing. Its automated correction calculations significantly reduce human error and ensure consistent results, while the digital interface provides detailed reports and documentation of the balancing process.