cross flow blade balancer

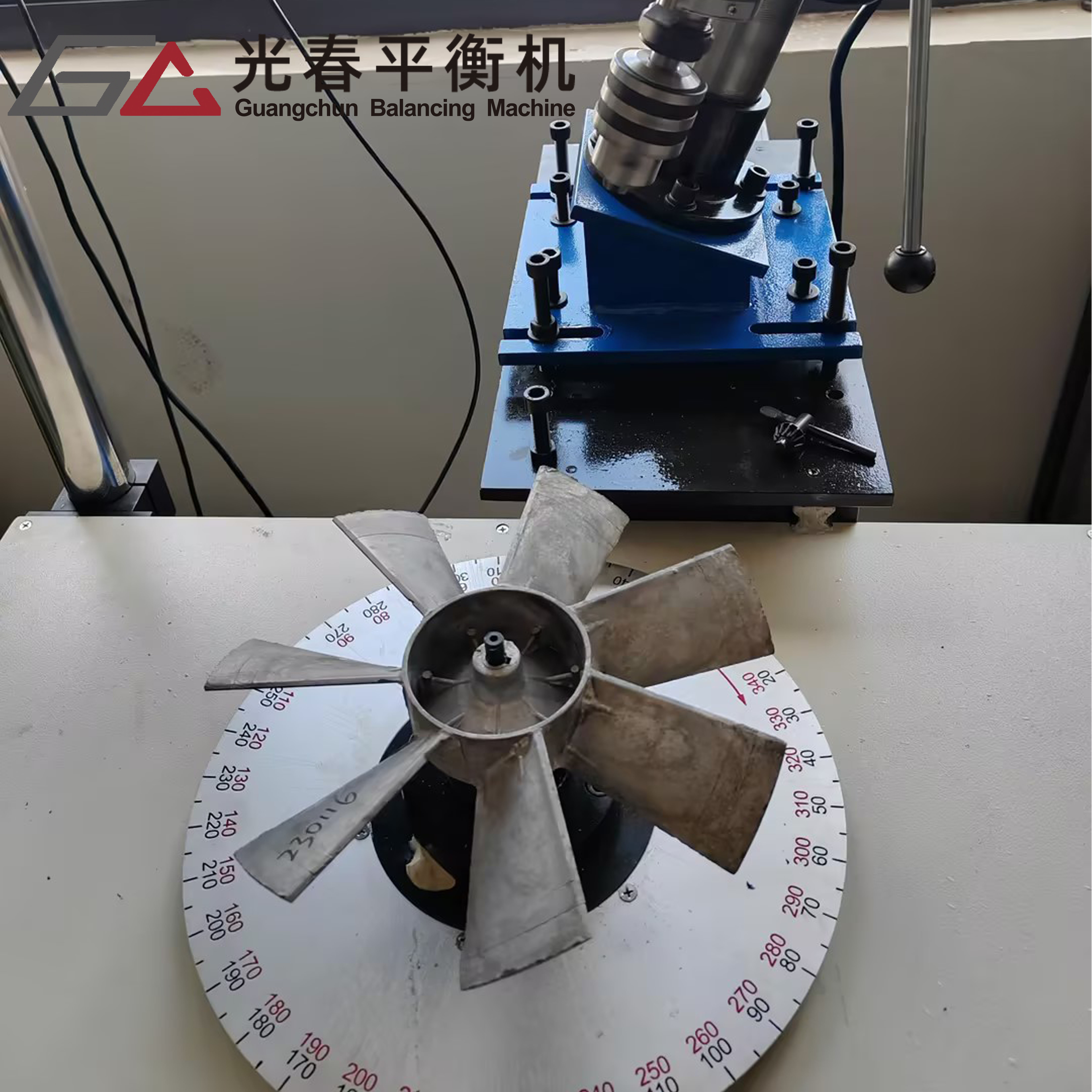

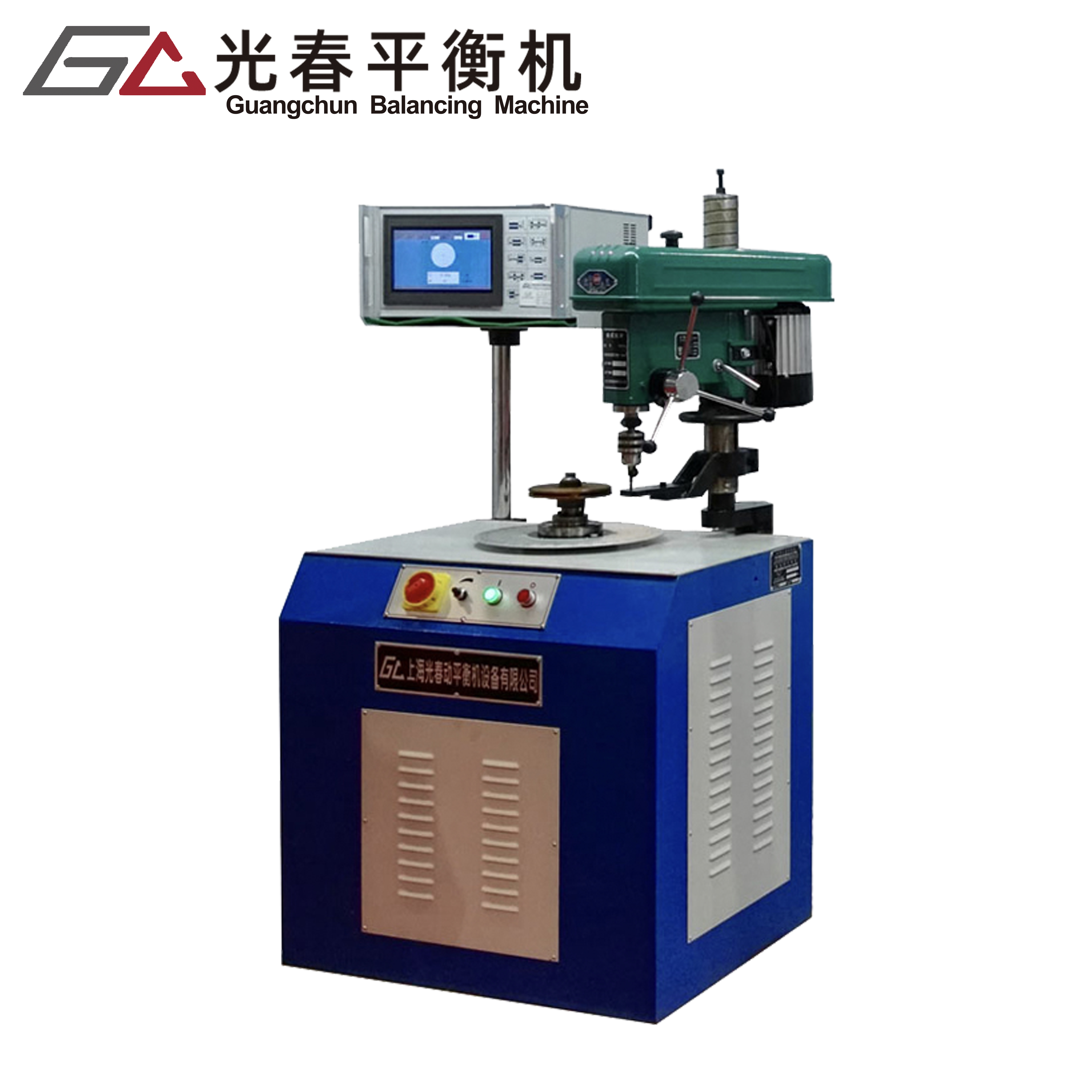

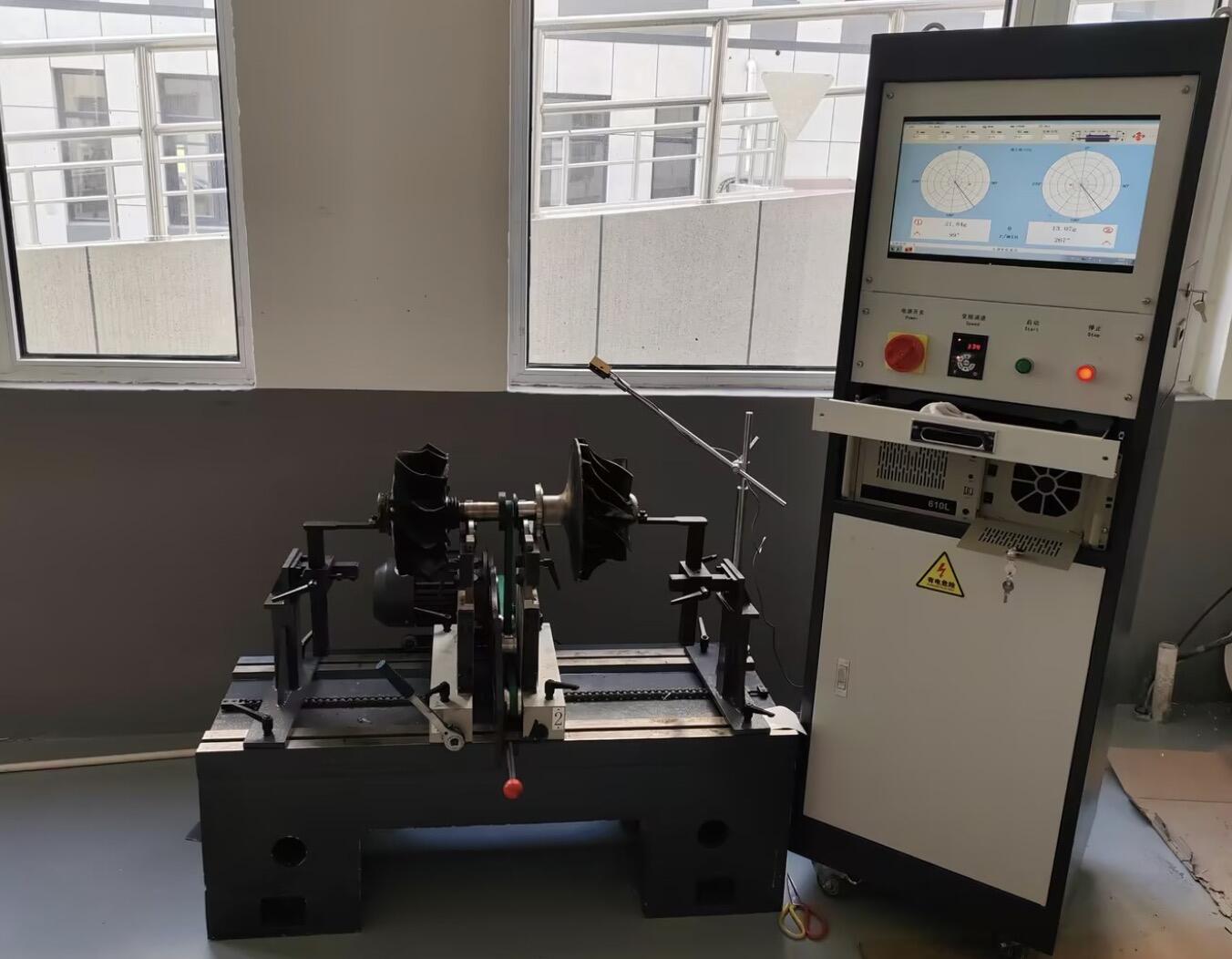

The cross flow blade balancer represents a sophisticated engineering solution designed for precise dynamic balancing of cross flow fans and similar rotating components. This advanced system combines mechanical precision with digital control technology to ensure optimal performance and longevity of cross flow blades. Operating through a combination of sensors and high-precision measurement tools, the balancer accurately detects imbalances across multiple planes of rotation. It employs advanced algorithms to calculate precise correction weights and positions, enabling perfect balance achievement. The system features automated measurement cycles that can process various blade sizes and configurations, making it versatile for different industrial applications. Its core functionality includes real-time monitoring of vibration levels, automatic weight placement recommendations, and comprehensive analysis of balance quality. The technology incorporates user-friendly interfaces that allow operators to monitor and adjust balancing parameters with minimal training. Applications span across HVAC systems, industrial ventilation equipment, and specialized cooling solutions where cross flow fans are critical components. The balancer's precision contributes significantly to reducing mechanical wear, energy consumption, and operational noise levels while extending equipment lifespan.