Modern automotive and industrial applications demand precise performance from turbocharger systems, where turbochargerturbine balancing machines play a critical role in ensuring optimal operation. These specialized machines have revolutionized how manufacturers approach quality control in turbocharger production, providing unmatched precision in detecting and correcting imbalance issues that can lead to premature component failure, reduced efficiency, and costly repairs.

The sophisticated technology behind turbochargerturbine balancing machines represents decades of engineering advancement, incorporating advanced sensors, digital processing capabilities, and automated correction systems. These machines address the fundamental challenge of maintaining perfect rotational balance in high-speed turbocharger assemblies, where even microscopic imbalances can cause devastating vibrations at operating speeds exceeding 200,000 RPM. Understanding the principles and applications of these balancing systems is essential for automotive manufacturers, repair facilities, and industrial maintenance teams.

Understanding Turbocharger Balance Requirements

Critical Balance Parameters

Turbocharger systems operate under extreme conditions that demand exceptional precision in component balance. The rotating assembly, consisting of the turbine wheel, shaft, and compressor wheel, must maintain perfect dynamic equilibrium to prevent destructive vibrations. Turbochargerturbine balancing machines measure residual imbalance with remarkable accuracy, typically detecting deviations as small as 0.1 grams at specified radii.

The balance quality requirements for turbocharger components follow international standards, with most applications requiring Grade G2.5 or better according to ISO 1940 specifications. This stringent requirement stems from the operational speeds involved, where centrifugal forces amplify even minor imbalances exponentially. Professional turbochargerturbine balancing machines can achieve these exacting standards through advanced measurement algorithms and precision correction capabilities.

Impact of Imbalance on Performance

Unbalanced turbocharger assemblies create cascading problems throughout the entire system, starting with bearing stress and progressing to seal failure, oil leakage, and ultimately complete component destruction. The high-frequency vibrations generated by imbalanced rotors can resonate through engine mounting systems, creating noise, vibration, and harshness issues that affect vehicle comfort and reliability.

Modern turbochargerturbine balancing machines address these concerns by providing comprehensive analysis of both static and dynamic imbalance conditions. Static imbalance occurs when the center of gravity does not coincide with the rotational axis, while dynamic imbalance involves uneven mass distribution along the rotor length. Both conditions require precise correction using specialized equipment capable of determining correction weights and their optimal placement locations.

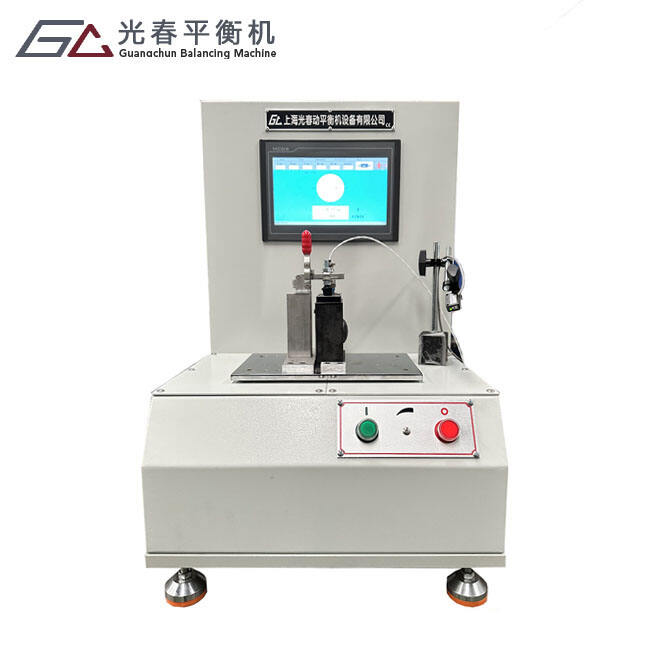

Technology and Design Features

Sensor Systems and Measurement Accuracy

Contemporary turbochargerturbine balancing machines employ sophisticated vibration sensors and displacement transducers to detect minute variations in rotor motion. Piezoelectric accelerometers capture vibration signatures with exceptional sensitivity, while laser displacement sensors provide non-contact measurement capabilities for applications requiring the highest precision. These sensors work in conjunction with advanced signal processing systems that filter noise and extract meaningful balance information.

The measurement accuracy of professional-grade turbochargerturbine balancing machines typically exceeds industry requirements by significant margins, ensuring reliable results across diverse operating conditions. Digital signal processing algorithms compensate for environmental factors, machine compliance effects, and coupling variations that might otherwise compromise measurement integrity. This technological sophistication enables operators to achieve repeatable results with minimal training and setup time.

Drive Systems and Operational Flexibility

Modern balancing systems incorporate various drive mechanisms to accommodate different turbocharger configurations and testing requirements. Belt-driven systems provide smooth acceleration and excellent speed control, while self-driven configurations allow testing at actual operating speeds using the turbocharger's own aerodynamic forces. The turbochargerturbine balancing machines with self-driven capabilities offer unique advantages for applications requiring testing at maximum operational speeds.

Variable speed control systems enable comprehensive analysis across the entire operating range, identifying critical speed resonances and ensuring balance quality at all relevant frequencies. These advanced drive systems incorporate safety features such as overspeed protection, emergency braking, and containment shields to protect operators and equipment during high-speed testing operations.

Applications and Industry Benefits

Manufacturing Quality Control

In production environments, turbochargerturbine balancing machines serve as critical quality control checkpoints, verifying that each assembled unit meets stringent balance specifications before shipment. Automated systems can process hundreds of units per day while maintaining consistent accuracy and documentation requirements. Integration with manufacturing execution systems enables real-time quality monitoring and statistical process control.

The economic benefits of implementing comprehensive balancing protocols extend far beyond immediate production costs. Properly balanced turbochargers experience significantly longer service life, reduced warranty claims, and improved customer satisfaction. Manufacturing facilities utilizing advanced turbochargerturbine balancing machines report substantial reductions in field failures and associated service costs.

Repair and Remanufacturing Operations

Service centers and remanufacturing facilities rely heavily on turbochargerturbine balancing machines to restore used components to original specifications. The rebuilding process often involves replacing worn bearings, seals, and other components that can affect rotational balance. Professional balancing equipment ensures that rebuilt turbochargers deliver performance equivalent to new units.

The diagnostic capabilities of modern balancing systems help technicians identify root causes of failure, enabling more effective repair strategies and improved customer education. Detailed balance reports provide documentation for warranty claims and help establish maintenance intervals based on actual operating conditions rather than arbitrary time or mileage schedules.

Selection Criteria and Specifications

Capacity and Size Requirements

Choosing appropriate turbochargerturbine balancing machines requires careful consideration of the intended application range, including maximum rotor weight, diameter, and speed requirements. Automotive turbochargers typically weigh between 1 and 20 kilograms, while industrial and marine applications may require equipment capable of handling much larger assemblies. The machine's working envelope must accommodate the longest rotors expected in the application.

Speed capability represents another critical specification, as different turbocharger designs operate across widely varying speed ranges. Passenger car applications typically require testing capabilities up to 250,000 RPM, while some specialized applications may demand even higher speeds. Professional turbochargerturbine balancing machines must provide adequate speed range with appropriate safety margins and containment provisions.

Accuracy and Repeatability Standards

Balance measurement accuracy directly impacts the quality of finished products and the efficiency of correction procedures. Industry-leading turbochargerturbine balancing machines achieve measurement uncertainties below 5% of the actual imbalance, enabling precise correction even for components requiring the highest balance grades. Repeatability specifications ensure consistent results across multiple operators and testing sessions.

Calibration procedures and traceability requirements vary by industry and application, with aerospace and medical device manufacturers typically demanding more stringent documentation than automotive applications. Modern balancing systems incorporate automated calibration verification routines and maintain detailed measurement histories for quality assurance purposes.

Maintenance and Operational Considerations

Routine Maintenance Requirements

Proper maintenance of turbochargerturbine balancing machines ensures continued accuracy and reliability throughout their operational life. Regular calibration verification using certified test rotors confirms measurement system integrity and compliance with relevant standards. Mechanical components such as drive belts, bearings, and coupling systems require periodic inspection and replacement according to manufacturer recommendations.

Environmental factors significantly impact balancing machine performance, particularly temperature variations, vibration isolation, and air quality. Climate-controlled installation environments provide optimal conditions for precision measurements, while proper foundation design minimizes external vibration influences. Regular cleaning of optical components and sensor surfaces maintains measurement accuracy and prevents contamination-related errors.

Training and Safety Protocols

Operating turbochargerturbine balancing machines safely requires comprehensive training covering both equipment operation and rotor handling procedures. High-speed testing involves significant stored energy that can cause serious injury if safety protocols are not followed. Proper containment systems, emergency shutdown procedures, and personal protective equipment requirements must be understood and consistently applied.

Certification programs offered by equipment manufacturers provide structured training curricula covering theory, operation, and troubleshooting procedures. Advanced courses address specialized applications, maintenance procedures, and integration with quality management systems. Ongoing training ensures operators remain current with evolving technology and industry best practices.

Future Trends and Technological Advances

Automation and Industry 4.0 Integration

The evolution of turbochargerturbine balancing machines continues toward greater automation and integration with manufacturing information systems. Artificial intelligence algorithms optimize correction strategies, reducing cycle times and material waste while improving balance quality. Predictive maintenance systems monitor equipment condition and schedule service interventions before problems affect production.

Cloud-based data management platforms enable remote monitoring, performance analysis, and collaborative troubleshooting across multiple facilities. These systems aggregate operational data to identify trends, optimize processes, and develop improved balancing strategies. Integration with enterprise resource planning systems streamlines workflow management and inventory control for balancing consumables and spare parts.

Enhanced Measurement Capabilities

Advanced sensor technologies continue to expand the capabilities of turbochargerturbine balancing machines, enabling more comprehensive analysis of rotor behavior and system interactions. Multi-plane balancing capabilities address complex rotor geometries with distributed mass characteristics, while real-time monitoring systems provide continuous feedback during correction procedures.

Emerging technologies such as digital twin modeling and virtual reality interfaces promise to revolutionize how operators interact with balancing systems. These innovations will enable more intuitive operation, enhanced training experiences, and improved troubleshooting capabilities. The continued miniaturization of sensor technology will enable embedded monitoring systems within turbochargers themselves, providing real-time balance feedback during actual operation.

FAQ

What factors determine the accuracy requirements for turbochargerturbine balancing machines

The accuracy requirements for turbochargerturbine balancing machines depend primarily on the intended application, operating speed range, and quality standards. Automotive applications typically require measurement uncertainties below 5% of actual imbalance, while aerospace and medical applications may demand even higher precision. The balance grade specification, usually defined according to ISO 1940 standards, directly influences the required measurement accuracy and correction capabilities.

How do self-driven balancing capabilities benefit turbocharger testing

Self-driven balancing systems allow testing at actual operating speeds using the turbocharger's own aerodynamic forces, eliminating potential coupling effects and measurement artifacts associated with external drive systems. This capability enables verification of balance quality under conditions that closely replicate actual service environments, providing more representative results and identifying potential issues that might not appear during conventional testing methods.

What maintenance intervals are recommended for professional balancing equipment

Maintenance intervals for turbochargerturbine balancing machines vary based on usage intensity and operating environment, but most manufacturers recommend calibration verification every 30 days for production environments and quarterly for occasional-use applications. Mechanical components such as drive belts and bearings typically require inspection every 500 operating hours, with replacement intervals determined by actual condition and manufacturer specifications. Environmental monitoring systems should be checked weekly to ensure optimal measurement conditions.

Can existing balancing machines be upgraded to handle modern turbocharger requirements

Many existing balancing systems can be upgraded with modern electronics, software, and sensor packages to meet current turbocharger balancing requirements. However, upgrades are limited by the mechanical capabilities of the original machine, particularly maximum speed capacity and structural rigidity. Professional evaluation by qualified service technicians can determine the feasibility and cost-effectiveness of upgrading versus purchasing new equipment designed specifically for modern turbochargerturbine balancing machines applications.

Table of Contents

- Understanding Turbocharger Balance Requirements

- Technology and Design Features

- Applications and Industry Benefits

- Selection Criteria and Specifications

- Maintenance and Operational Considerations

- Future Trends and Technological Advances

-

FAQ

- What factors determine the accuracy requirements for turbochargerturbine balancing machines

- How do self-driven balancing capabilities benefit turbocharger testing

- What maintenance intervals are recommended for professional balancing equipment

- Can existing balancing machines be upgraded to handle modern turbocharger requirements