Modern industrial operations demand precision engineering to maintain competitive advantage and operational efficiency. The selection of appropriate equipment for rotational component balancing has become increasingly critical as manufacturing tolerances tighten and performance expectations rise. General balancing machines represent essential tools for achieving optimal rotational harmony in various industrial components, from automotive parts to aerospace assemblies. Understanding the technical specifications, operational capabilities, and application requirements ensures organizations invest in equipment that delivers long-term value and operational excellence.

Understanding Balancing Machine Fundamentals

Principles of Dynamic Balancing Technology

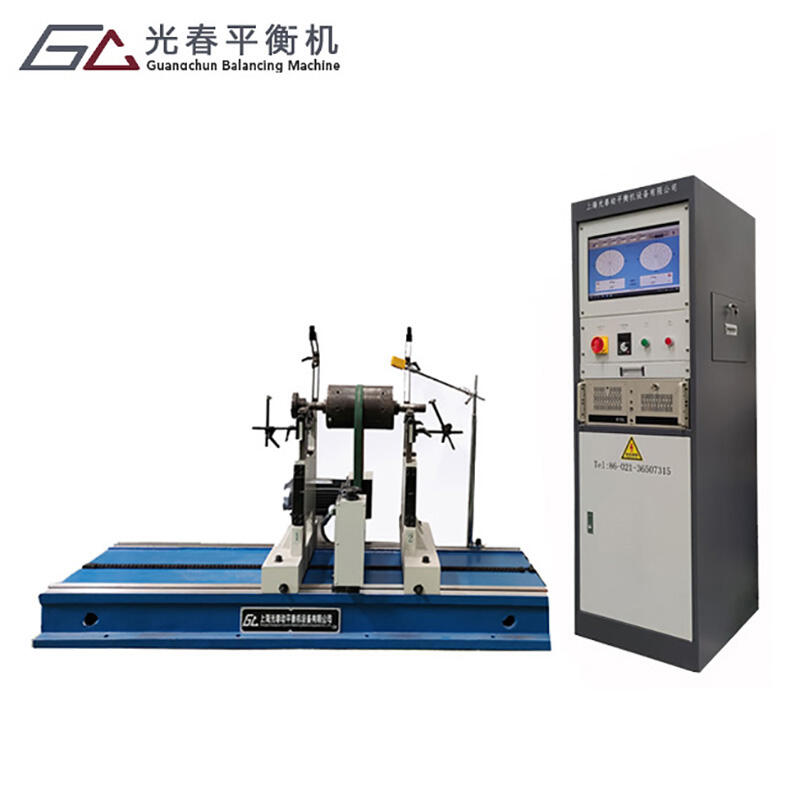

Dynamic balancing technology forms the cornerstone of modern rotational equipment maintenance and manufacturing quality control. General balancing machines utilize sophisticated measurement systems to detect mass distribution irregularities that cause vibration and premature wear in rotating components. These systems employ accelerometers and force sensors to measure the magnitude and phase of unbalance forces during component rotation. The fundamental principle involves spinning the component at predetermined speeds while monitoring vibration patterns to identify correction points and required mass adjustments.

Advanced general balancing machines incorporate digital signal processing capabilities that analyze complex vibration signatures and provide precise correction instructions. The measurement process typically involves multiple sensing points to accommodate various component geometries and balancing requirements. Modern systems can distinguish between static unbalance, which occurs when the center of mass is displaced from the rotation axis, and dynamic unbalance, where the principal axis of inertia does not align with the rotation axis. This distinction is crucial for achieving optimal balancing results across different component types and operational conditions.

Types of Unbalance and Correction Methods

Rotational components experience different types of unbalance that require specific correction approaches using general balancing machines. Static unbalance occurs when the component's center of gravity does not coincide with its geometric center, creating a tendency for the heavy side to settle at the bottom when stationary. Dynamic unbalance involves couples that create moments around the rotation axis, typically requiring correction in multiple planes. Couple unbalance represents a special case where the center of mass lies on the rotation axis, but the principal axis of inertia is inclined to the rotation axis.

Correction methods vary depending on component design and application requirements. Material removal techniques include drilling, milling, or grinding to eliminate excess mass from heavy spots. Material addition approaches involve welding, adhesive bonding, or mechanical attachment of correction weights to light areas. Some general balancing machines feature automated correction capabilities that execute removal or addition operations based on measurement results. The selection of correction method depends on factors such as component material, operating environment, and required balance quality grade according to international standards.

Industrial Applications and Requirements

Automotive Industry Applications

The automotive industry represents one of the largest application segments for general balancing machines, with stringent requirements for component precision and operational smoothness. Engine components such as crankshafts, flywheels, and rotors require precise balancing to minimize vibration and noise while maximizing fuel efficiency and component longevity. Transmission components including clutch assemblies, torque converters, and drive shafts benefit from professional balancing to ensure smooth power transfer and reduced driveline vibration.

Modern automotive manufacturing facilities integrate general balancing machines into production lines to maintain consistent quality standards and meet increasingly stringent emissions requirements. Wheel and tire assemblies require balancing to prevent steering wheel vibration and uneven tire wear patterns. Brake rotors and drums benefit from balancing procedures to eliminate pedal pulsation and ensure consistent braking performance. The automotive industry's emphasis on noise, vibration, and harshness reduction drives continuous advancement in balancing machine technology and application techniques.

Aerospace and Defense Applications

Aerospace applications demand the highest levels of precision from general balancing machines due to extreme operating conditions and safety requirements. Turbine engines, propellers, and rotor assemblies operate at high speeds under significant stress, making precise balancing critical for operational safety and component reliability. Military applications often require specialized balancing capabilities for weapons systems, radar equipment, and specialized machinery that must perform reliably in harsh environments.

Aerospace general balancing machines typically feature enhanced measurement accuracy and specialized fixtures to accommodate complex component geometries. The industry requires compliance with strict quality standards and certification procedures that validate balancing machine performance and measurement repeatability. Satellite and spacecraft components require ultra-precise balancing to ensure proper orientation and operational stability in space environments. The aerospace sector drives innovation in balancing technology through demanding applications that push the boundaries of measurement accuracy and operational capability.

Technical Specifications and Performance Criteria

Load Capacity and Size Considerations

Load capacity represents a fundamental specification for general balancing machines, determining the range of components that can be effectively balanced. Capacity considerations include maximum component weight, diameter, and length limitations that define the machine's operational envelope. Belt-driven systems typically accommodate medium to heavy components with weight capacities ranging from 160kg to 500kg or more, depending on machine design and construction. The relationship between component size and balancing accuracy requires careful consideration to ensure optimal measurement results.

Machine frame construction and bearing systems directly impact load capacity and measurement stability. Heavy-duty general balancing machines feature reinforced frames and precision bearing assemblies that maintain measurement accuracy under varying load conditions. Component support systems must provide adequate rigidity while minimizing interference with natural vibration modes during measurement. The selection of appropriate load capacity ensures optimal performance across the intended range of applications while maintaining measurement accuracy and operational reliability.

Measurement Accuracy and Resolution

Measurement accuracy defines the capability of general balancing machines to detect and quantify unbalance conditions with precision and repeatability. Modern systems achieve unbalance measurement accuracies within 0.1 gram-millimeter per kilogram or better, depending on component characteristics and operational conditions. Resolution specifications indicate the smallest unbalance condition that can be reliably detected and corrected. High-resolution systems enable precise balancing of critical components where small unbalances can significantly impact performance.

Calibration procedures ensure measurement accuracy remains within specified tolerances throughout the machine's operational life. General balancing machines incorporate reference standards and calibration fixtures that validate system performance and enable traceability to national measurement standards. Environmental factors such as temperature, humidity, and foundation stability can influence measurement accuracy, requiring appropriate compensation techniques and operational procedures. Advanced systems feature automatic calibration capabilities that maintain accuracy without manual intervention, improving operational efficiency and measurement reliability.

Selection Criteria for Industrial Applications

Application-Specific Requirements

Selecting appropriate general balancing machines requires careful analysis of specific application requirements and operational constraints. Component characteristics such as size, weight, material, and geometry influence machine selection decisions. Production volume requirements determine whether manual or automated systems provide optimal cost-effectiveness and operational efficiency. Quality standards and certification requirements may mandate specific measurement capabilities and documentation features that influence equipment selection.

Environmental considerations include facility space limitations, power requirements, and integration with existing production equipment. Some general balancing machines require specialized foundations or vibration isolation systems to achieve optimal measurement accuracy. Operator skill levels and training requirements factor into selection decisions, as more sophisticated systems may require extensive operator education. Long-term service and support availability ensures continued operational capability and measurement accuracy throughout the equipment's operational life.

Cost-Benefit Analysis and ROI Considerations

Investment analysis for general balancing machines must consider both initial acquisition costs and long-term operational benefits. Direct cost factors include equipment purchase price, installation expenses, and operator training requirements. Indirect benefits include reduced warranty claims, improved product quality, and enhanced customer satisfaction. Production efficiency improvements through automated balancing capabilities can provide significant return on investment through reduced labor costs and increased throughput.

Quality improvements achieved through professional balancing translate into competitive advantages and market differentiation. Reduced field failures and warranty costs provide quantifiable benefits that support investment justification. Energy efficiency improvements in balanced rotating equipment contribute to operational cost reductions and environmental sustainability goals. General balancing machines often qualify for accelerated depreciation schedules and tax incentives that improve overall investment attractiveness and return on investment calculations.

Installation and Operational Considerations

Facility Requirements and Setup

Proper installation of general balancing machines requires careful attention to facility requirements and environmental conditions. Foundation specifications typically require reinforced concrete bases with specific thickness and reinforcement patterns to minimize vibration transmission and ensure measurement stability. Electrical requirements include appropriate power distribution, grounding systems, and electromagnetic interference shielding to protect sensitive measurement circuits from external interference sources.

Space allocation must accommodate not only the machine footprint but also component handling equipment, storage areas, and operator workspace requirements. Ventilation systems may be necessary to remove heat generated by drive systems and electronic components. Lighting requirements ensure operators can safely and effectively perform balancing operations and component handling tasks. General balancing machines benefit from temperature-controlled environments that minimize thermal effects on measurement accuracy and component dimensional stability.

Maintenance and Calibration Procedures

Regular maintenance ensures general balancing machines continue to deliver accurate measurements and reliable operation throughout their service life. Preventive maintenance schedules include bearing lubrication, drive belt inspection and replacement, and electronic system calibration verification. Measurement system calibration requires periodic verification using certified reference standards to ensure continued accuracy and traceability to national standards.

Operator training programs ensure personnel understand proper operating procedures, safety requirements, and maintenance responsibilities. Documentation systems track calibration history, maintenance activities, and measurement results to support quality system requirements and equipment performance monitoring. Service contracts with equipment manufacturers provide access to specialized technical support, replacement parts, and calibration services that maintain optimal system performance. Condition monitoring systems can provide early warning of potential maintenance issues before they impact measurement accuracy or operational reliability.

FAQ

What factors determine the appropriate capacity for general balancing machines in industrial applications

Capacity selection for general balancing machines depends on the maximum weight, diameter, and length of components to be balanced, along with production volume requirements and facility constraints. Belt-driven systems typically handle components ranging from 160kg to 500kg, with larger capacities available for specialized applications. Consider future expansion needs and component variety to ensure long-term equipment utility and operational flexibility.

How do general balancing machines achieve measurement accuracy and what factors can affect precision

Modern general balancing machines use precision force sensors and accelerometers combined with digital signal processing to achieve measurement accuracies within 0.1 gram-millimeter per kilogram. Environmental factors such as temperature variation, foundation stability, and electromagnetic interference can impact accuracy. Proper calibration procedures and controlled operating environments help maintain optimal measurement precision throughout the equipment's operational life.

What maintenance requirements ensure optimal performance of general balancing machines

Regular maintenance for general balancing machines includes bearing lubrication, drive system inspection, calibration verification, and electronic system checks. Preventive maintenance schedules should be established based on manufacturer recommendations and operating conditions. Proper operator training and documentation systems support maintenance effectiveness and ensure continued measurement accuracy and operational reliability.

How do general balancing machines integrate with existing production systems and quality control processes

Integration of general balancing machines into production systems requires consideration of material handling capabilities, data communication interfaces, and quality documentation requirements. Modern systems feature digital connectivity options for data integration with manufacturing execution systems and statistical process control applications. Proper planning ensures seamless workflow integration while maintaining production efficiency and quality standards throughout the manufacturing process.

Table of Contents

- Understanding Balancing Machine Fundamentals

- Industrial Applications and Requirements

- Technical Specifications and Performance Criteria

- Selection Criteria for Industrial Applications

- Installation and Operational Considerations

-

FAQ

- What factors determine the appropriate capacity for general balancing machines in industrial applications

- How do general balancing machines achieve measurement accuracy and what factors can affect precision

- What maintenance requirements ensure optimal performance of general balancing machines

- How do general balancing machines integrate with existing production systems and quality control processes