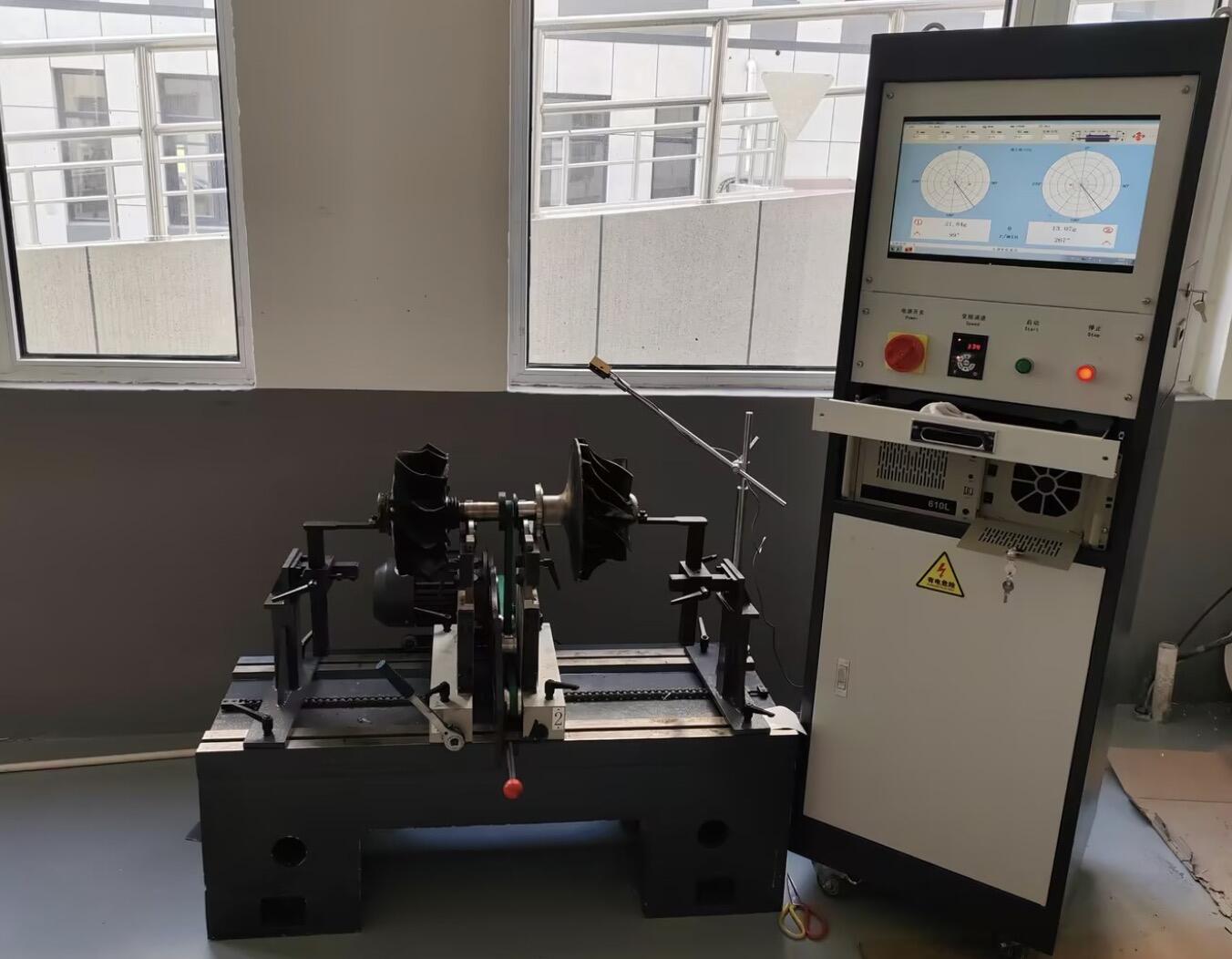

In the rapidly evolving automotive and aerospace industries, precision balancing of turbocharger turbines has become paramount for optimal performance and longevity. Modern turbochargerturbine balancing machines represent sophisticated engineering solutions that ensure these critical rotating components operate with minimal vibration and maximum efficiency. These specialized machines have revolutionized how manufacturers and service centers approach turbocharger maintenance and production quality control. The demand for high-precision balancing equipment continues to grow as turbocharged engines become increasingly prevalent across passenger vehicles, commercial trucks, marine applications, and industrial power generation systems. Understanding the capabilities and features of leading turbochargerturbine balancing machines enables businesses to make informed decisions that directly impact their operational efficiency and customer satisfaction.

Advanced Precision Balancing Technology

High-Speed Spindle Capabilities

The foundation of exceptional turbochargerturbine balancing machines lies in their high-speed spindle systems that can accommodate the operational characteristics of turbocharger components. Premium balancing systems feature motorized spindles capable of reaching speeds up to 80,000 RPM or higher, matching the actual operating conditions of modern turbochargers. These spindles incorporate advanced bearing technologies, including air bearings or precision ball bearing assemblies, to minimize friction and ensure accurate measurements during the balancing process. Temperature compensation systems within these machines account for thermal expansion effects that could otherwise compromise measurement accuracy at high rotational speeds.

Leading manufacturers integrate sophisticated vibration isolation systems that decouple the measuring system from external disturbances, ensuring consistent and repeatable results. The spindle drive systems typically employ variable frequency drives with precise speed control algorithms that maintain stable rotation throughout the entire balancing procedure. Modern machines also incorporate automatic runup and rundown capabilities that gradually accelerate and decelerate the test component, protecting delicate turbine wheels from sudden mechanical stress while gathering comprehensive vibration data across the entire speed range.

Multi-Plane Correction Systems

Contemporary turbochargerturbine balancing machines excel in multi-plane correction capabilities, addressing both static and dynamic imbalances that commonly occur in turbocharger assemblies. These systems utilize multiple vibration sensors positioned strategically around the spindle assembly to capture comprehensive imbalance information from different planes of rotation. Advanced signal processing algorithms analyze the amplitude and phase relationships of vibration signals to determine precise correction weights and their optimal placement locations on the rotor assembly.

The correction calculation software employed in premium balancing machines incorporates influence coefficient methods that account for the complex interactions between correction weights applied in different planes. This mathematical approach ensures that corrections made in one plane do not adversely affect the balance condition in adjacent planes, resulting in superior overall balance quality. Many modern systems also feature automatic correction weight calculation with tolerance checking, alerting operators when calculated correction weights exceed predetermined limits that might indicate underlying mechanical issues with the test component.

Industrial Applications and Performance Standards

Automotive Turbocharger Manufacturing

The automotive industry represents the largest market segment for turbochargerturbine balancing machines, where manufacturers require consistent quality control processes to meet stringent OEM specifications. Production-grade balancing systems must accommodate high-volume throughput requirements while maintaining measurement accuracy within tight tolerances, typically ranging from 0.1 to 0.5 grams per correction plane. These machines integrate seamlessly with automated production lines, featuring pneumatic or servo-driven loading systems that position turbocharger assemblies accurately and repeatably for testing.

Quality management systems within these machines automatically document balancing results, generating detailed reports that include before and after measurements, correction weight information, and compliance status relative to established specifications. Advanced systems incorporate statistical process control capabilities that monitor balancing trends over time, providing early warning indicators of potential process drift or tooling wear. The integration of these machines with enterprise resource planning systems enables real-time production monitoring and quality traceability throughout the manufacturing process.

Aftermarket Service and Remanufacturing

Turbocharger service centers and remanufacturing facilities rely heavily on versatile turbochargerturbine balancing machines that can accommodate diverse turbocharger designs from multiple manufacturers. These applications require flexible tooling systems that can quickly adapt to different shaft configurations, bearing arrangements, and overall assembly geometries. Service-oriented balancing machines typically feature modular fixture designs with quick-change capabilities that minimize setup time between different turbocharger models.

The diagnostic capabilities of modern balancing machines prove invaluable in service applications, where technicians must evaluate the condition of used turbocharger components before determining appropriate repair procedures. Advanced vibration analysis features can identify specific failure modes such as bearing wear, shaft distortion, or turbine wheel damage that might not be immediately apparent through visual inspection. These diagnostic insights enable service technicians to provide accurate repair estimates and recommend appropriate corrective actions to restore turbocharger performance to original specifications.

Key Features and Selection Criteria

Measurement Accuracy and Repeatability

The measurement accuracy of turbochargerturbine balancing machines directly impacts the quality of balanced components and the overall efficiency of production or service operations. Premium balancing systems achieve measurement repeatability within ±0.05 grams or better, ensuring consistent results across multiple test cycles of identical components. This level of precision requires sophisticated vibration sensors, typically accelerometers or velocity transducers, with high sensitivity and excellent frequency response characteristics across the operational speed range of turbocharger applications.

Environmental factors significantly influence measurement accuracy, necessitating careful consideration of installation requirements and operating conditions. Leading balancing machines incorporate temperature compensation algorithms that automatically adjust measurements based on ambient temperature variations. Vibration isolation systems, including pneumatic or active isolation platforms, minimize the effects of external disturbances from nearby machinery or building vibrations. Regular calibration procedures using certified reference standards ensure long-term measurement accuracy and compliance with applicable quality standards.

Software Integration and User Interface

Modern turbochargerturbine balancing machines feature sophisticated software packages that streamline the balancing process while providing comprehensive data management capabilities. Intuitive touchscreen interfaces guide operators through standardized balancing procedures, reducing the likelihood of procedural errors and ensuring consistent results regardless of operator experience level. These systems typically include pre-programmed balancing routines for common turbocharger models, complete with appropriate speed settings, measurement parameters, and acceptance criteria.

Data management features enable detailed record keeping of all balancing operations, including component identification, test parameters, measurement results, and correction actions taken. Advanced systems support integration with quality management systems and manufacturing execution systems, providing seamless data flow throughout the production or service environment. Remote diagnostic capabilities allow equipment manufacturers to provide technical support and troubleshooting assistance, minimizing downtime and ensuring optimal machine performance.

Maintenance and Operational Considerations

Preventive Maintenance Requirements

Reliable operation of turbochargerturbine balancing machines requires comprehensive preventive maintenance programs that address both mechanical and electronic components. Spindle assemblies represent critical maintenance points, requiring regular inspection of bearing condition, lubrication system performance, and drive belt tension where applicable. High-speed operation subjects these components to significant wear over time, making scheduled maintenance essential for maintaining measurement accuracy and preventing costly failures.

Vibration sensors and measurement electronics require periodic calibration verification using certified reference standards to ensure continued accuracy. Environmental factors such as temperature fluctuations, humidity levels, and contamination can affect sensor performance over time. Regular cleaning procedures and protective measures help maintain optimal sensor function while extending component service life. Documentation of all maintenance activities enables trend analysis and optimization of maintenance intervals based on actual operating conditions and component performance history.

Training and Operator Competency

Effective utilization of turbochargerturbine balancing machines requires comprehensive operator training that covers both theoretical balancing principles and practical machine operation procedures. Training programs should address proper component handling techniques, safety protocols, and troubleshooting procedures for common operational issues. Understanding the relationship between imbalance characteristics and vibration signatures enables operators to identify potential component defects beyond simple imbalance conditions.

Ongoing training updates ensure operators remain current with software enhancements, new balancing procedures, and evolving industry standards. Many equipment manufacturers provide comprehensive training packages that include hands-on instruction, detailed documentation, and ongoing technical support. Investment in operator competency development directly correlates with improved productivity, reduced scrap rates, and enhanced overall equipment effectiveness.

Market Leading Models and Technologies

High-Capacity Production Systems

Production-oriented turbochargerturbine balancing machines designed for high-volume manufacturing environments incorporate advanced automation features that maximize throughput while maintaining consistent quality standards. These systems typically feature multiple spindle configurations that enable simultaneous balancing of multiple components, significantly reducing cycle times in mass production applications. Automated loading and unloading systems integrated with conveyor networks provide seamless material flow throughout the balancing process.

Advanced production systems incorporate real-time process monitoring capabilities that track key performance indicators such as cycle time, first-pass yield rates, and overall equipment effectiveness. Statistical process control features automatically identify trends that might indicate process drift or equipment degradation, enabling proactive maintenance actions before quality issues develop. Integration with enterprise manufacturing systems provides comprehensive visibility into balancing operations and their impact on overall production efficiency.

Portable and Flexible Solutions

Portable turbochargerturbine balancing machines serve specialized applications where components cannot be easily transported to fixed balancing stations or where field service capabilities are required. These systems sacrifice some measurement accuracy and capacity in exchange for enhanced mobility and setup flexibility. Modern portable systems achieve measurement capabilities sufficient for many service and repair applications while providing the convenience of on-site balancing capabilities.

Flexible balancing systems designed for research and development applications or low-volume production incorporate modular designs that can accommodate a wide range of component sizes and configurations. These systems typically feature adjustable spindle heights, variable fixture arrangements, and comprehensive measurement capabilities that support both routine balancing operations and detailed vibration analysis for component development purposes. The versatility of these systems makes them particularly valuable for organizations working with diverse turbocharger designs or developing new turbocharger technologies.

FAQ

What accuracy levels can modern turbochargerturbine balancing machines achieve

Modern turbochargerturbine balancing machines can achieve measurement repeatability within ±0.05 grams or better for production applications, with some specialized systems reaching even higher precision levels. The actual accuracy depends on factors such as spindle quality, vibration isolation, sensor technology, and environmental conditions. Premium systems incorporate temperature compensation and advanced signal processing to maintain consistent accuracy across varying operating conditions.

How do these machines accommodate different turbocharger sizes and configurations

Turbochargerturbine balancing machines typically feature modular fixture systems with adjustable components that can accommodate various shaft diameters, bearing arrangements, and overall assembly geometries. Many systems include quick-change tooling that enables rapid setup transitions between different turbocharger models. Advanced systems may incorporate automatic fixture adjustment capabilities that reduce setup time and eliminate potential operator errors during configuration changes.

What maintenance requirements are necessary for optimal machine performance

Regular maintenance for turbochargerturbine balancing machines includes spindle bearing inspection and lubrication, vibration sensor calibration verification, cleaning of measurement surfaces, and software updates. Preventive maintenance schedules typically range from daily cleaning and inspection routines to annual comprehensive calibration procedures. Proper maintenance documentation and trending analysis help optimize maintenance intervals and identify potential issues before they impact measurement accuracy or machine availability.

Can these machines integrate with existing production management systems

Yes, modern turbochargerturbine balancing machines typically feature comprehensive connectivity options including Ethernet, serial communications, and industrial fieldbus protocols that enable seamless integration with manufacturing execution systems, quality management systems, and enterprise resource planning platforms. This integration provides real-time production monitoring, automated data collection, and comprehensive traceability throughout the manufacturing or service process. Many systems also support remote diagnostic capabilities for enhanced technical support and troubleshooting assistance.

Table of Contents

- Advanced Precision Balancing Technology

- Industrial Applications and Performance Standards

- Key Features and Selection Criteria

- Maintenance and Operational Considerations

- Market Leading Models and Technologies

-

FAQ

- What accuracy levels can modern turbochargerturbine balancing machines achieve

- How do these machines accommodate different turbocharger sizes and configurations

- What maintenance requirements are necessary for optimal machine performance

- Can these machines integrate with existing production management systems