Manufacturing efficiency has become the cornerstone of competitive advantage in today's industrial landscape. Companies constantly seek innovative solutions to optimize their production processes, reduce downtime, and enhance product quality. Among the most critical tools in achieving these objectives are general balancing machines, which have revolutionized how manufacturers approach rotational component testing and quality assurance. These sophisticated devices have transformed manufacturing operations by providing precise measurements, reducing vibrations, and ensuring optimal performance of rotating machinery across diverse industrial applications.

The implementation of general balancing machines in manufacturing environments has demonstrated measurable improvements in productivity metrics, cost reduction, and overall operational excellence. These machines serve as essential quality control instruments that detect and correct imbalances in rotating components before they reach final assembly or customer delivery. By integrating advanced balancing technology into production workflows, manufacturers can achieve higher throughput rates while maintaining stringent quality standards that meet international certification requirements.

Understanding the Technology Behind General Balancing Machines

Core Components and Operating Principles

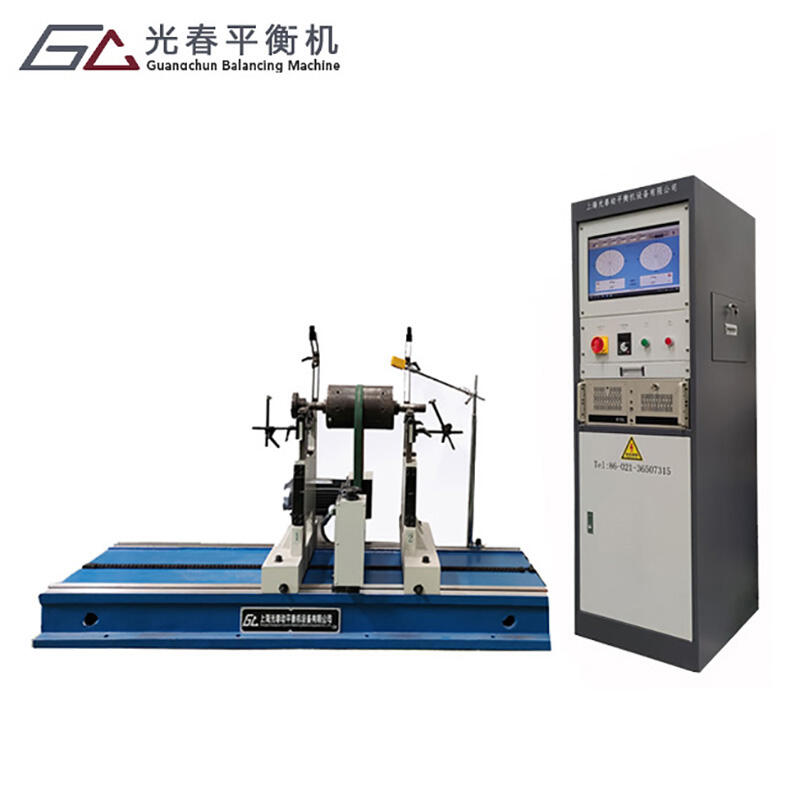

General balancing machines operate on fundamental physics principles that measure centrifugal forces generated by rotating objects. The core technology incorporates precision sensors, digital processing units, and sophisticated software algorithms that analyze vibration patterns and calculate corrective actions. These machines utilize piezoelectric accelerometers or force transducers to detect minute imbalances during rotation cycles, converting mechanical vibrations into electrical signals for digital analysis.

The mechanical framework of general balancing machines consists of rigid pedestals, adjustable cradles, and variable-speed drive systems that accommodate diverse component geometries and weight ranges. Modern machines feature computer-controlled interfaces that provide real-time feedback, allowing operators to monitor balancing progress and implement corrections with exceptional accuracy. The integration of digital technology has enhanced measurement precision to levels previously unattainable with manual balancing methods.

Advanced Measurement Capabilities

Contemporary general balancing machines offer multi-plane balancing capabilities that address complex rotational dynamics in industrial components. These systems can simultaneously measure static and dynamic imbalances, providing comprehensive analysis of rotational behavior across different operating speeds. The measurement resolution has improved dramatically with modern sensor technology, enabling detection of imbalances as small as 0.1 gram-millimeter in precision applications.

The data acquisition systems in advanced general balancing machines capture thousands of measurement points per rotation, creating detailed profiles of component behavior. This information enables manufacturers to identify specific problem areas, track quality trends, and implement preventive maintenance strategies that reduce unexpected equipment failures. The analytical capabilities extend beyond simple balance correction to include vibration analysis, bearing condition monitoring, and rotational speed optimization.

Manufacturing Efficiency Improvements Through Balancing Technology

Production Speed and Throughput Enhancement

The implementation of general balancing machines significantly accelerates production cycles by eliminating manual balancing procedures that consume valuable operator time. Automated balancing processes can complete full component analysis and correction within minutes, compared to hours required for traditional methods. This time reduction translates directly into increased throughput capacity, allowing manufacturers to process more components per shift while maintaining consistent quality standards.

Production scheduling becomes more predictable when general balancing machines are integrated into manufacturing workflows. The consistent processing times enable accurate capacity planning and resource allocation, reducing bottlenecks that typically occur with manual quality control procedures. Manufacturers report throughput improvements ranging from 25% to 60% after implementing automated balancing solutions in their production lines.

Quality Consistency and Defect Reduction

General balancing machines eliminate human variability factors that contribute to inconsistent quality outcomes in manual balancing operations. The standardized measurement protocols ensure that every component receives identical evaluation criteria, resulting in uniform quality levels across production batches. This consistency reduces customer complaints, warranty claims, and field service requirements that drain manufacturing resources.

The precision capabilities of modern general balancing machines enable early detection of manufacturing defects that might otherwise escape traditional quality control processes. By identifying problematic components before assembly, manufacturers can prevent costly rework situations and reduce scrap rates significantly. The comprehensive data logging capabilities also support continuous improvement initiatives by providing detailed analytics on quality trends and process performance.

Cost Reduction Strategies Through Balancing Implementation

Labor Cost Optimization

The automation capabilities of general balancing machines reduce dependency on skilled technicians for routine balancing operations. While initial equipment investment requires capital expenditure, the long-term labor cost savings justify the investment through reduced staffing requirements and increased productivity per operator. Companies typically achieve return on investment within 18 to 24 months after implementing automated balancing solutions.

Training requirements for general balancing machines are considerably lower than traditional manual balancing methods, as operators work with intuitive software interfaces rather than complex mechanical adjustments. This reduction in training time and complexity allows manufacturers to cross-train personnel more efficiently and maintain consistent operations during shift changes or personnel transitions. The simplified operation also reduces the risk of operator errors that could damage expensive components or equipment.

Maintenance and Operational Savings

Properly balanced rotating components experience significantly reduced wear rates, extending service life and reducing replacement frequency. General balancing machines help manufacturers achieve optimal balance levels that minimize bearing stress, reduce vibration-related fatigue, and extend equipment reliability. These improvements translate into lower maintenance costs and reduced downtime for both production equipment and end-user applications.

The predictive maintenance capabilities enabled by general balancing machines allow manufacturers to schedule maintenance activities proactively rather than reactively. By monitoring balance conditions over time, companies can identify degradation trends and plan maintenance interventions during scheduled downtime periods. This approach minimizes unexpected failures and reduces emergency repair costs that typically exceed planned maintenance expenses.

Industry Applications and Versatility

Automotive and Transportation Sector

The automotive industry relies heavily on general balancing machines for engine components, transmission parts, and wheel assemblies that require precise rotational balance for optimal performance. These applications demand exceptional accuracy to meet noise, vibration, and harshness standards that directly impact customer satisfaction. Automotive manufacturers use general balancing machines throughout their supply chains to ensure consistent quality from component suppliers to final assembly operations.

Electric vehicle manufacturing has created new challenges for balancing technology as motor rotors and battery cooling fans require different balancing approaches than traditional internal combustion engine components. General balancing machines have adapted to these requirements with specialized fixtures and measurement protocols that address the unique characteristics of electric drivetrain components. The precision requirements for electric motors often exceed those of conventional automotive parts, making advanced balancing technology essential for quality assurance.

Industrial Machinery and Equipment

Manufacturing equipment such as pumps, compressors, turbines, and motor assemblies depend on general balancing machines for optimal performance and reliability. These industrial applications often involve larger components and higher rotational speeds than automotive parts, requiring robust balancing equipment with enhanced measurement capabilities. The balancing requirements for industrial machinery directly impact energy efficiency, operational noise levels, and maintenance intervals.

Process industries including chemical processing, power generation, and oil refining utilize general balancing machines to maintain critical rotating equipment that operates continuously in demanding environments. The reliability of these systems depends on precise balance conditions that prevent excessive vibrations and premature component failure. General balancing machines enable manufacturers to achieve the tight tolerance requirements necessary for these critical applications.

Technology Integration and Future Developments

Digital Connectivity and Data Analytics

Modern general balancing machines incorporate industrial internet connectivity that enables real-time data sharing with manufacturing execution systems and quality management platforms. This integration allows manufacturers to correlate balancing data with other production metrics, identifying relationships between process variables and final product quality. The connectivity features support Industry 4.0 initiatives by providing comprehensive data visibility across manufacturing operations.

Cloud-based analytics platforms enhance the value of data collected by general balancing machines by providing advanced statistical analysis and predictive modeling capabilities. Manufacturers can identify trends across multiple production lines, compare performance between facilities, and optimize balancing parameters based on historical data analysis. These insights enable continuous improvement programs that drive ongoing efficiency enhancements and quality improvements.

Artificial Intelligence and Machine Learning

The integration of artificial intelligence algorithms in general balancing machines enables automatic optimization of balancing parameters based on component characteristics and historical performance data. Machine learning systems can predict optimal correction weights and positions, reducing the number of balancing cycles required to achieve target specifications. This technology advancement further accelerates production cycles while improving balancing accuracy.

Predictive analytics capabilities powered by artificial intelligence help manufacturers anticipate quality issues before they occur by analyzing patterns in balancing data and process variables. These systems can recommend preventive actions, schedule maintenance activities, and optimize production parameters to maintain consistent quality outcomes. The continuous learning capabilities ensure that general balancing machines become more efficient over time as they accumulate operational experience and data.

Implementation Strategies for Maximum Efficiency

Production Line Integration Planning

Successful implementation of general balancing machines requires careful analysis of existing production workflows and identification of optimal integration points. Manufacturers must consider component flow patterns, cycle time requirements, and operator training needs when planning balancing equipment installation. The physical layout should minimize material handling time while providing adequate space for equipment operation and maintenance access.

Capacity planning for general balancing machines involves analyzing production volumes, component mix, and balancing time requirements to determine appropriate equipment specifications and quantities. Manufacturers often implement multiple balancing stations to handle different component types or to provide backup capacity during maintenance periods. The scalability of balancing solutions allows companies to expand capacity as production volumes increase over time.

Training and Change Management

Effective implementation of general balancing machines requires comprehensive training programs that address both technical operation and quality system integration. Operators must understand measurement principles, software navigation, and troubleshooting procedures to maximize equipment utilization and maintain consistent results. The training programs should include hands-on experience with actual production components to ensure practical competency development.

Change management initiatives help manufacturing organizations adapt to new balancing procedures and quality standards that accompany general balancing machine implementation. Communication programs should emphasize the benefits of automated balancing while addressing concerns about job security or skill requirements. Successful implementations often include operator involvement in equipment selection and setup procedures to build ownership and acceptance of new technology.

FAQ

What types of components can be balanced using general balancing machines

General balancing machines accommodate a wide range of rotating components including engine crankshafts, motor rotors, pump impellers, turbine wheels, grinding wheels, and various shaft assemblies. The equipment can handle components ranging from small precision parts weighing grams to large industrial rotors weighing several thousand kilograms. Most modern general balancing machines feature adjustable fixtures and variable speed capabilities that enable balancing of diverse component geometries and specifications.

How accurate are measurements from general balancing machines

Contemporary general balancing machines achieve measurement accuracies typically within 0.1 to 1.0 gram-millimeter, depending on component size and balancing speed requirements. The actual accuracy depends on factors including sensor quality, mechanical rigidity of the machine frame, and environmental conditions such as temperature stability and vibration isolation. High-precision applications in industries like aerospace or medical devices may require even tighter tolerances that specialized balancing equipment can achieve.

What maintenance requirements do general balancing machines have

General balancing machines require routine maintenance including calibration verification, sensor cleaning, drive system lubrication, and software updates to maintain optimal performance. The calibration procedures typically involve using certified test weights to verify measurement accuracy and may be required monthly or quarterly depending on usage intensity and quality system requirements. Preventive maintenance schedules should include inspection of mechanical components, electrical connections, and safety systems to ensure reliable operation and operator safety.

How long does it take to balance a component using general balancing machines

Balancing cycle times vary based on component complexity, target specifications, and initial imbalance levels, but typically range from 2 to 15 minutes per component. Simple parts with moderate imbalance may require only a single measurement and correction cycle, while complex multi-plane components might need several iterations to achieve target specifications. Automated general balancing machines can often complete the entire process including loading, measuring, correction calculation, and unloading within these timeframes, making them highly efficient for production environments.

Table of Contents

- Understanding the Technology Behind General Balancing Machines

- Manufacturing Efficiency Improvements Through Balancing Technology

- Cost Reduction Strategies Through Balancing Implementation

- Industry Applications and Versatility

- Technology Integration and Future Developments

- Implementation Strategies for Maximum Efficiency

- FAQ