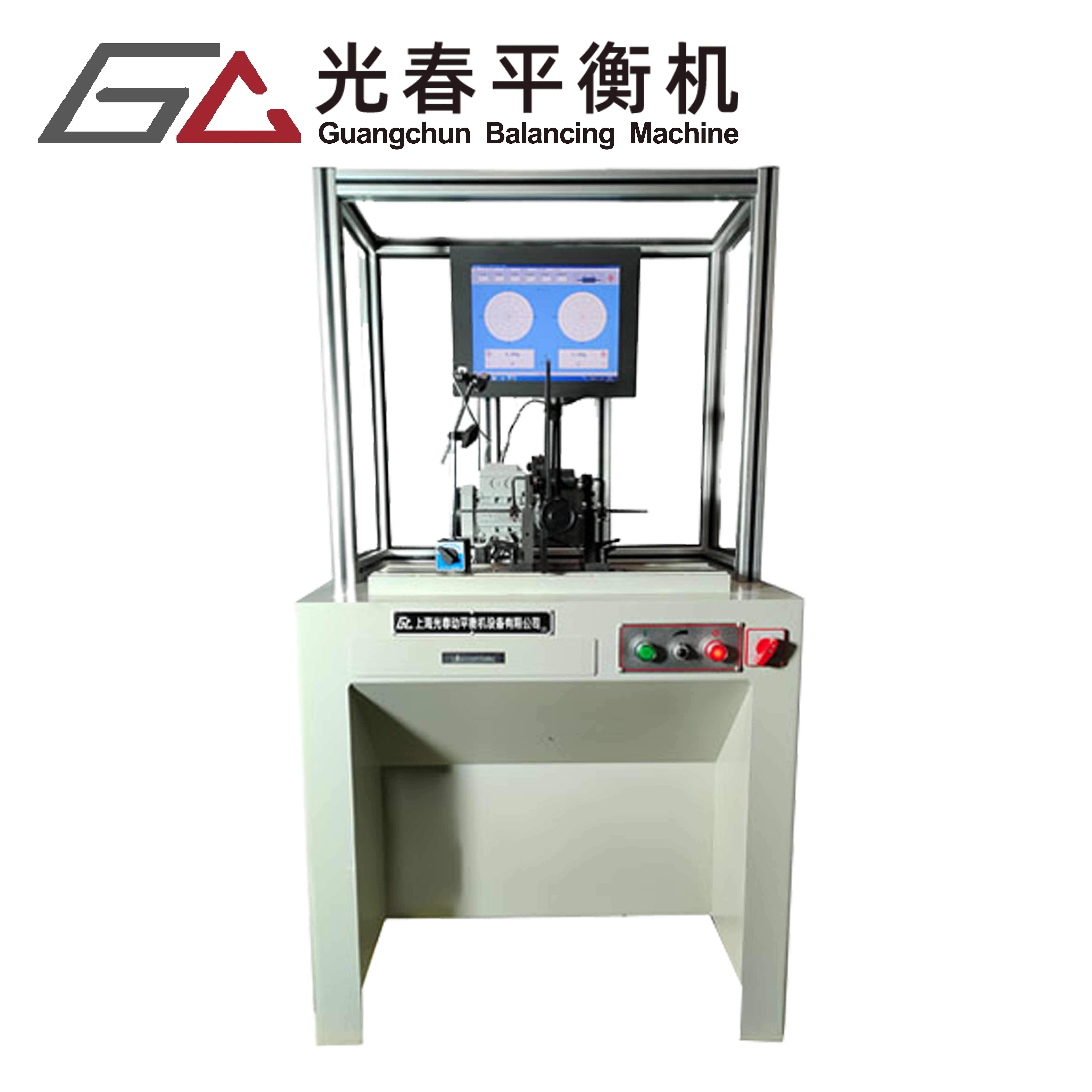

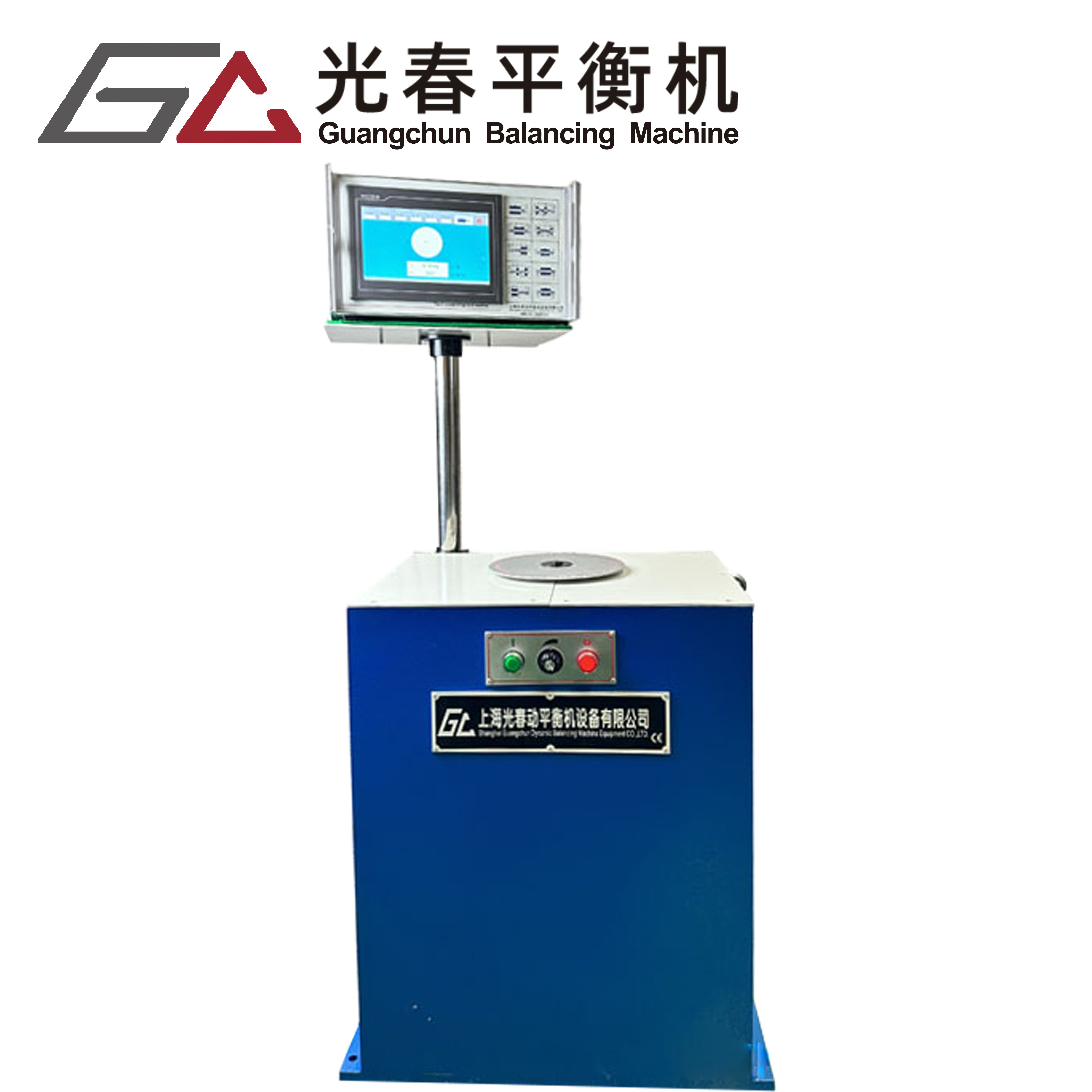

դաշտի հավասարակշռության մեքենան

Մեքենայի հավասարակշռությունը դաշտում մի կարևոր ախտորոշման և պահպանման գործիք է, որն նախագծված է չափելու և ճիշտ անել մեքենաների աշխատանքի ժամանակ իր տեղում անհավասարակշռությունը: Այս բարդ սարքավորումները օգտագործում են առաջադեմ զգայուն սենսորներ և թվային տեխնոլոգիաներ՝ թրթիռային օրինաչափությունները հայտնաբերելու, դինամիկ ուժերը վերլուծելու և ճշգրիտ հաշվարկելու համար հավասարակշռության համար անհրաժեշտ ճշտումները: Սարքը աշխատում է սարքավորումների վրա հատուկ կետերում թրթիռը չափելով, սովորաբար օգտագործելով արագացման կամ արագության սենսորներ, և մշակում է այդ տվյալները մասնագիտական ալգորիթմներով՝ որոշելու անհավասարակշռության տեղը և մեծությունը: Դաշտի հավասարակշռության մեքենաները հատկապես արժեքավոր են, քանի որ նրանք թույլ են տալիս հավասարակշռությունն իրականացնել անմիջապես վայրում՝ առանց սարքավորումների քամուրջ անելու, ինչն էական կերպով կրճատում է սպասարկման դադարեցման և կապված ծախսերը: Այս մեքենաները լայնորեն կիրառվում են տարբեր արդյունաբերություններում, ներառյալ էլեկտրաէներգիայի արտադրությունը, նավթաքիմիական մշակումը, թղթի արտադրությունը և HVAC համակարգերը: Նրանք հատկապես կարևոր են մեծ պտտվող սարքավորումների պահպանման համար, ինչպիսիք են արդյունաբերական օդափոխիչները, օդանետները, շարժիչները և պոմպերը: Տեխնոլոգիան ներառում է իրական ժամանակի հսկողության հնարավորություններ և կարող է կատարել ինչպես միահարթական, այնպես էլ երկհարթական հավասարակշռության գործողություններ, ինչն այն դարձնում է հարմար տարբեր տեսակի պտտվող սարքավորումների համար: Ժամանակակից դաշտային հավասարակշռության մեքենաները հաճախ ունեն հարմար միջերեսներ, ինքնաշխատ հաշվարկման գործընթացներ և լրիվ զեկուցման ֆունկցիաներ, որոնք օգնում են տեխնիկական անձնակազմին ճշգրիտ հավասարակշռության ճշտումներ կատարել արդյունավետ: