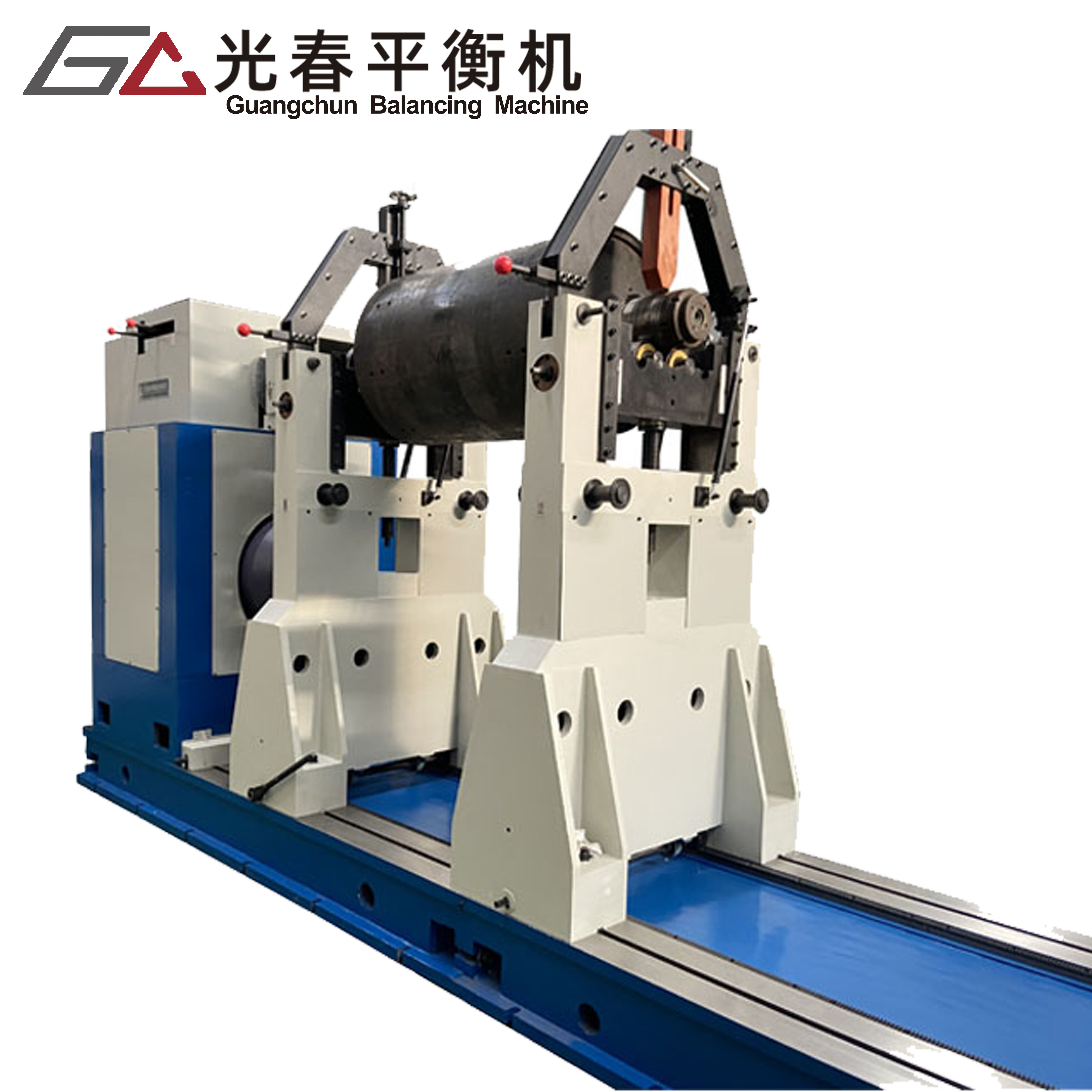

balancing machine for electric motors

A balancing machine for electric motors is a sophisticated piece of equipment designed to ensure optimal performance and longevity of motor components. This precision instrument measures and corrects any imbalance in rotating parts, particularly rotors and armatures, which is essential for maintaining smooth operation and preventing premature wear. The machine utilizes advanced sensors and computerized analysis systems to detect even minimal vibrations and weight disparities that could affect motor performance. Operating through both static and dynamic balancing principles, it can identify imbalances in multiple planes and provide precise correction recommendations. The technology incorporates high-resolution measurement capabilities that can detect imbalances as small as 0.0001 gram-inches, ensuring exceptional accuracy in the balancing process. Modern balancing machines feature user-friendly interfaces with real-time data display, automatic calculation of correction weights, and positions for optimal balance achievement. These machines are essential in manufacturing and maintenance operations, serving industries from automotive to industrial manufacturing, where motor reliability is crucial. The system's ability to handle various motor sizes and types, coupled with its automated calibration and self-diagnostic features, makes it an indispensable tool for quality control and performance optimization in electric motor production.