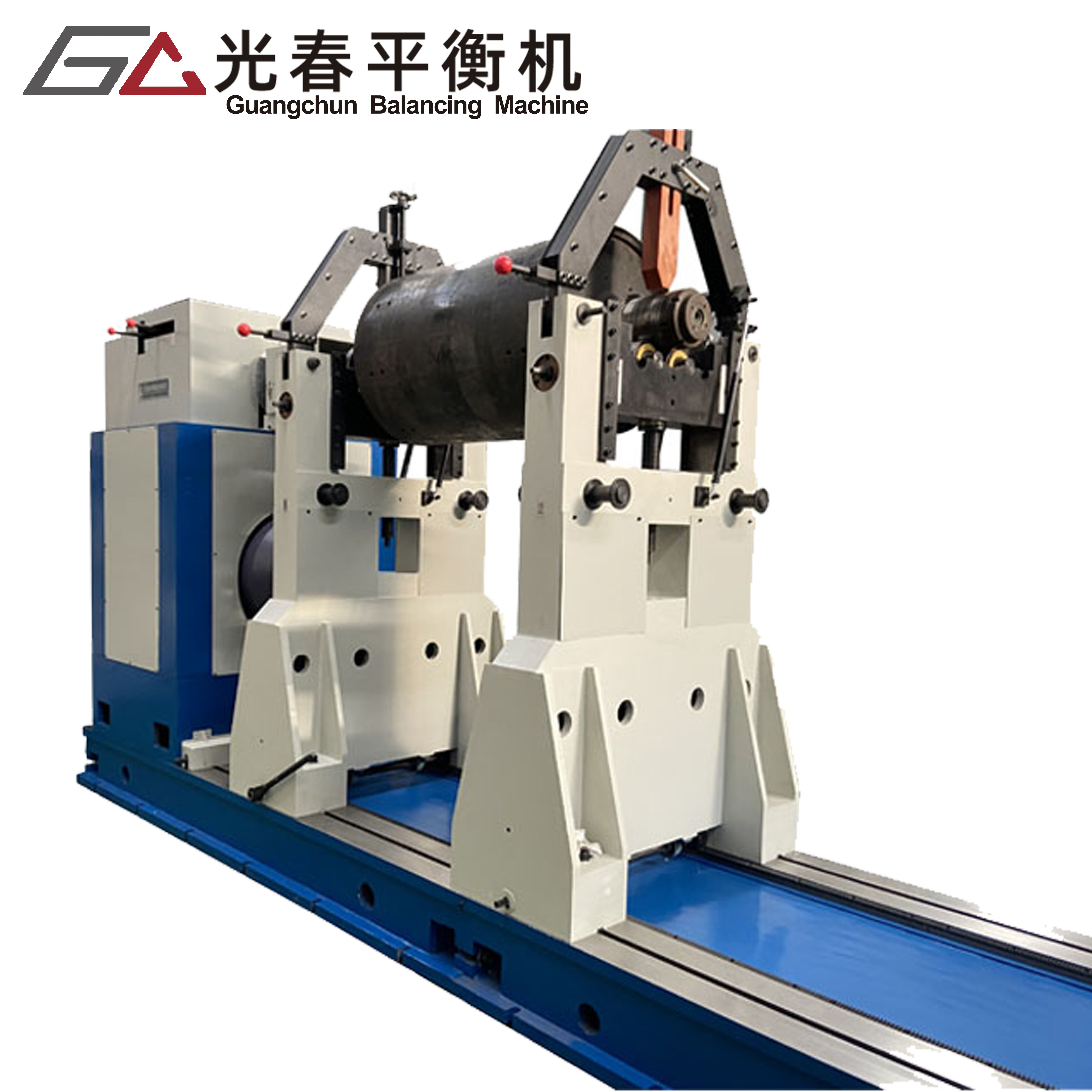

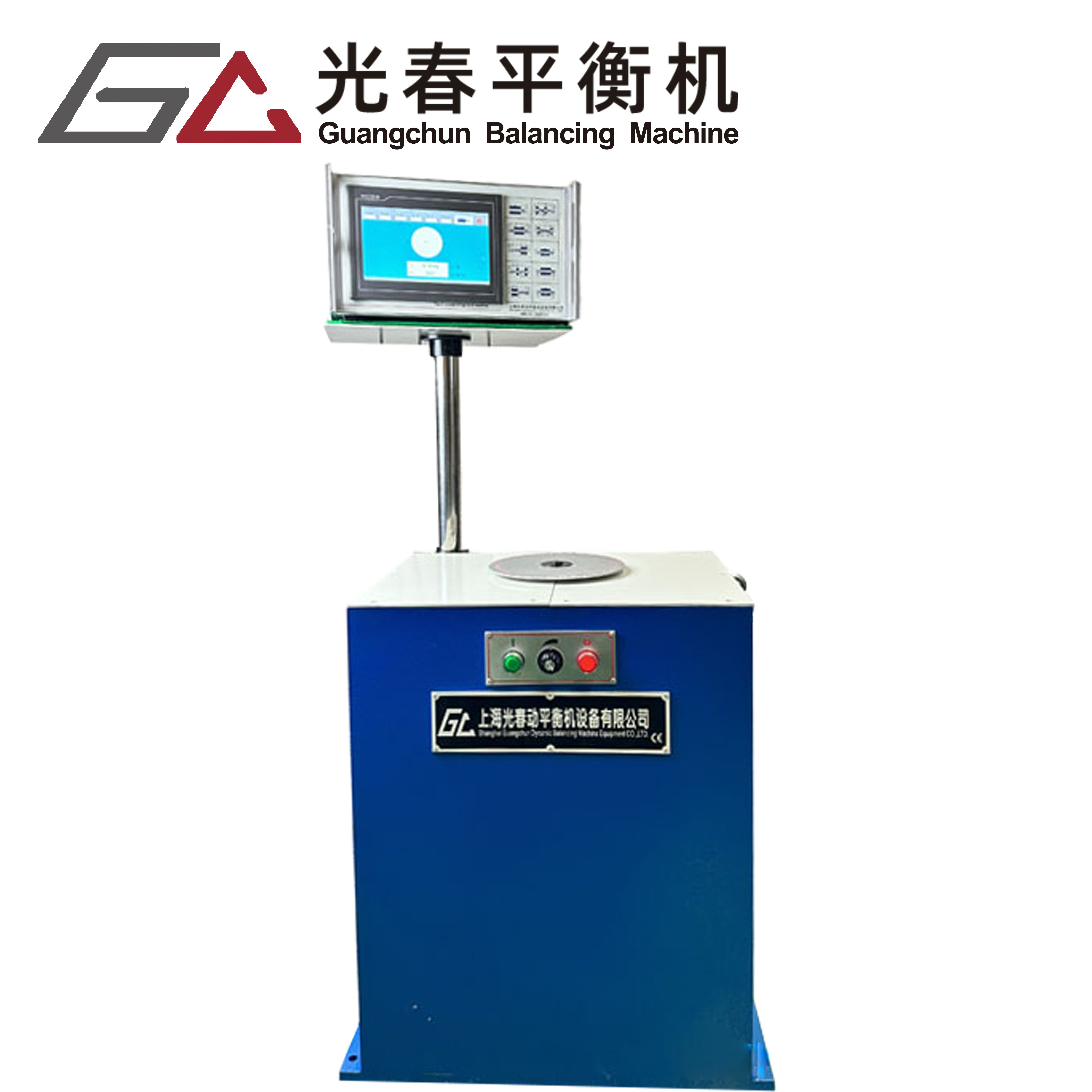

spindle motor balancing equipment

Spindle motor balancing equipment represents a crucial advancement in precision manufacturing technology, designed to ensure optimal performance and longevity of high-speed rotating machinery. This sophisticated system combines state-of-the-art sensors, digital analysis capabilities, and precise calibration mechanisms to achieve perfect rotational balance in spindle motors. The equipment utilizes advanced vibration analysis technology to detect and measure even the smallest imbalances in rotating components, operating across multiple planes to ensure comprehensive balancing. The system can handle various spindle sizes and types, accommodating speeds ranging from 300 to 30,000 RPM, making it versatile for different industrial applications. The equipment features real-time monitoring capabilities, allowing operators to observe and adjust balancing parameters during the process. Its integrated software system provides detailed analysis reports, including graphical representations of imbalance measurements and correction recommendations. The equipment includes automatic calculation of correction weights and positions, significantly reducing the time and expertise required for precise balancing operations. With its robust construction and precision engineering, the equipment ensures consistent and reliable results in industrial environments, contributing to enhanced manufacturing efficiency and reduced maintenance costs.