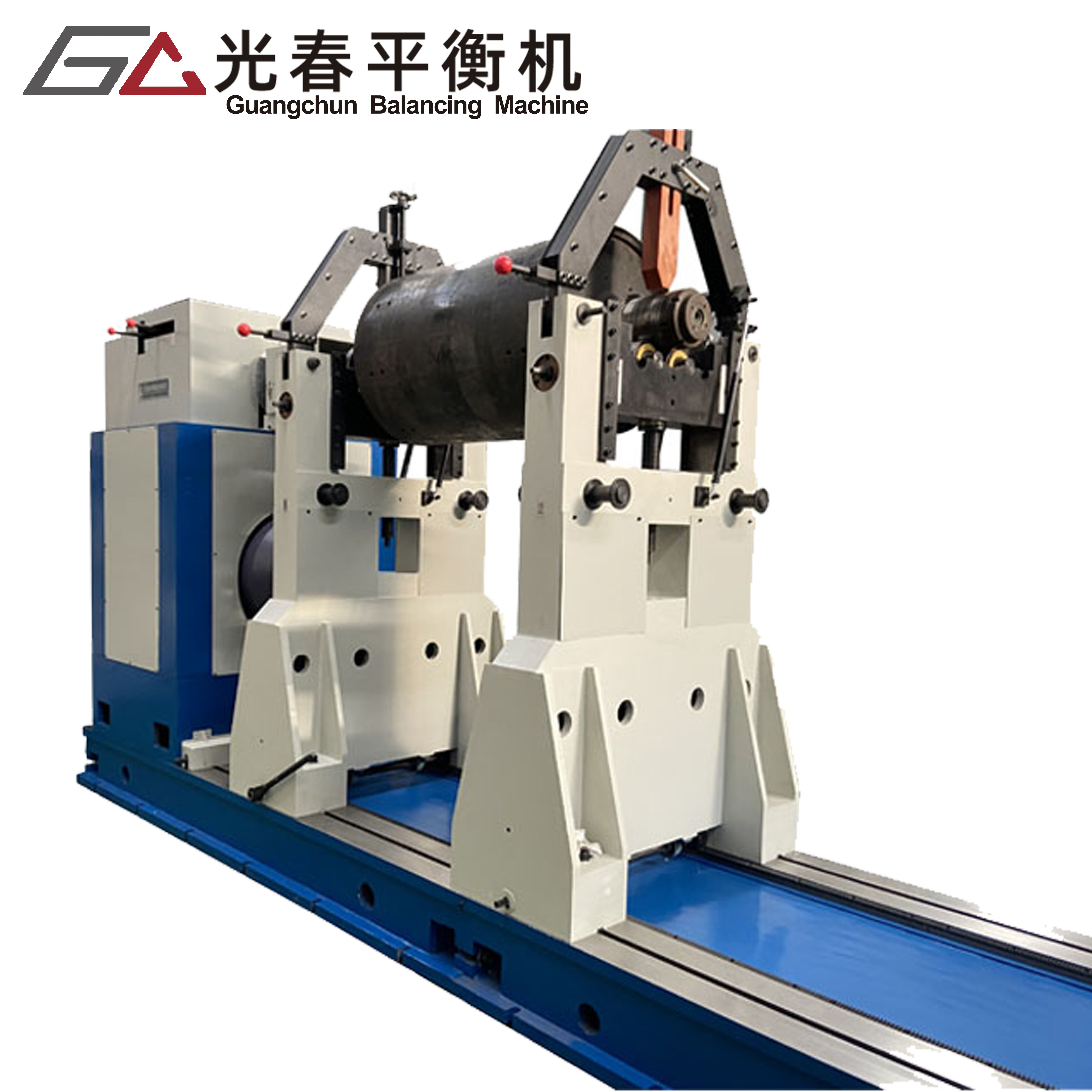

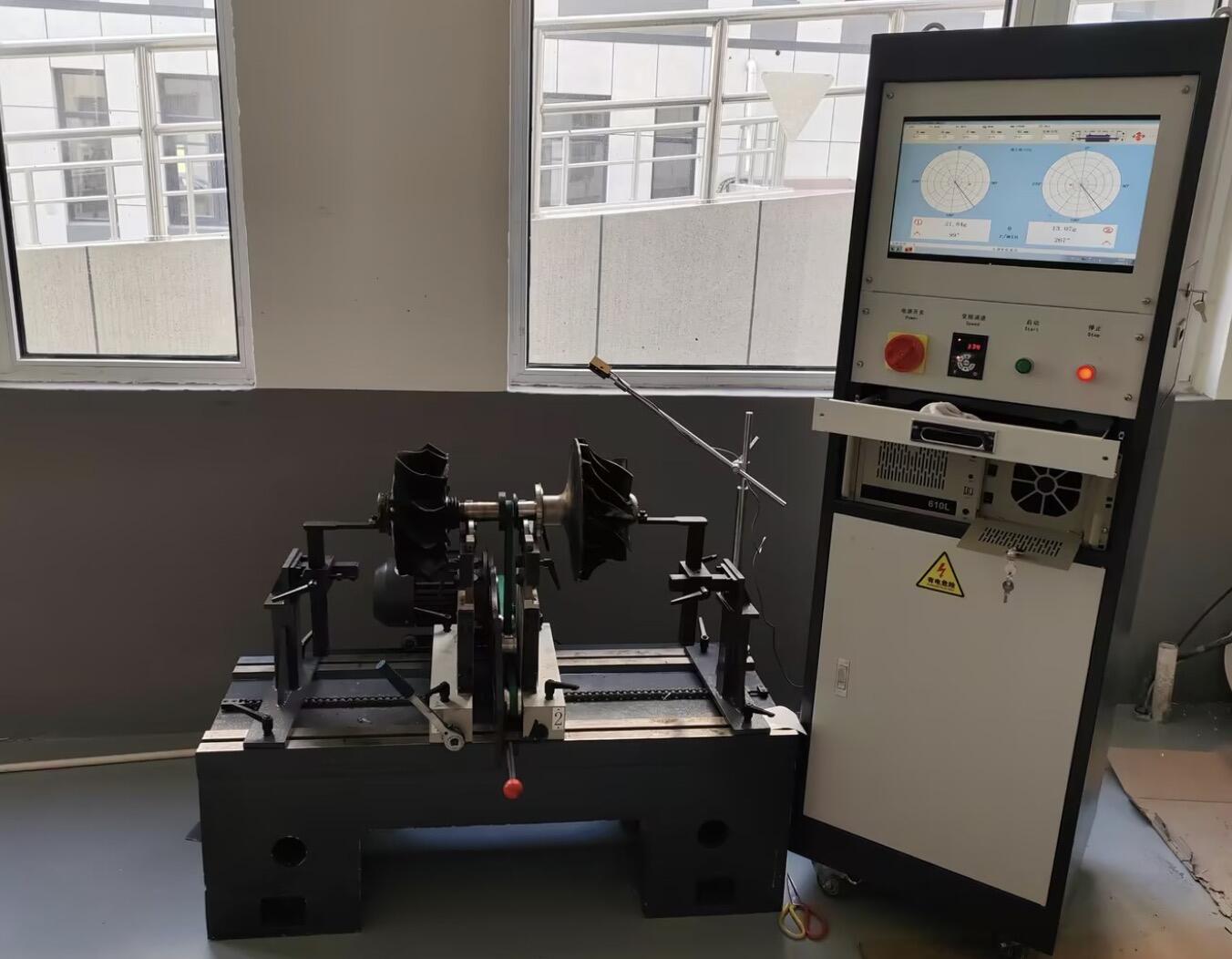

motor balancing machine

A motor balancing machine is a sophisticated piece of equipment designed to detect and correct imbalances in rotating components of motors and other mechanical devices. This precision instrument measures vibration levels and determines the exact location and magnitude of unbalance in motor rotors, ensuring optimal performance and longevity. The machine operates by spinning the rotor at specific speeds while sensitive sensors detect any irregularities in rotation. Using advanced digital technology and computerized analysis, it provides real-time data on the balance condition of the component being tested. The machine can handle various rotor sizes and weights, making it versatile for different industrial applications. Modern motor balancing machines incorporate features such as automatic measurement cycles, digital displays, and user-friendly interfaces that simplify the balancing process. These machines are essential in manufacturing, maintenance, and repair facilities where motor performance is critical. They help prevent common issues associated with unbalanced rotors, such as excessive vibration, bearing wear, and reduced efficiency. The technology employs precise measuring instruments and sophisticated software algorithms to calculate correction weights and their exact placement positions. This ensures that motors operate smoothly and efficiently after balancing.