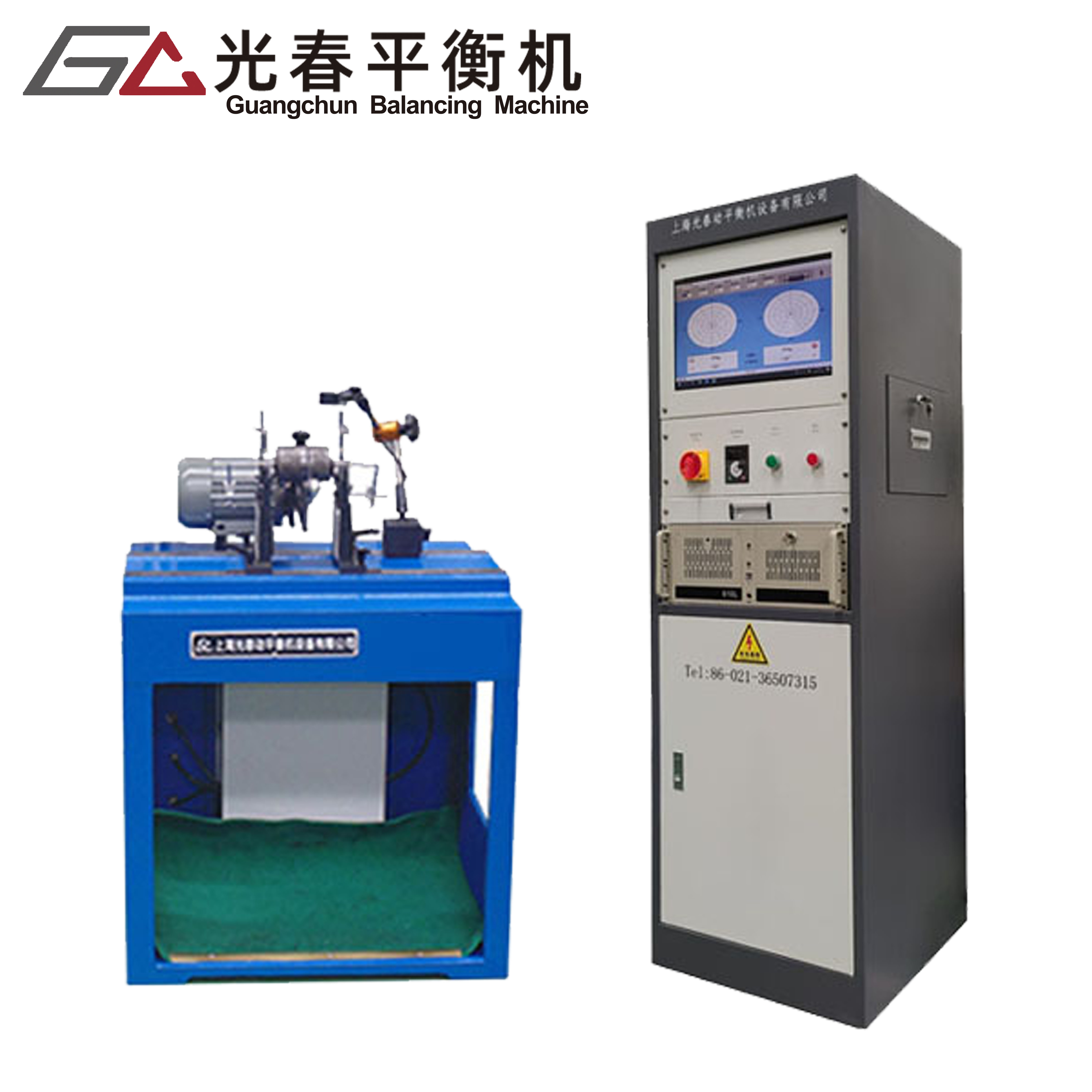

armature balancing machine

The armature balancing machine is a sophisticated piece of equipment designed to ensure optimal performance and longevity of rotating electrical components. This precision instrument measures and corrects imbalances in armatures, which are essential components in electric motors, generators, and other rotating machinery. The machine operates by spinning the armature at specific speeds while utilizing highly sensitive sensors to detect any irregularities in weight distribution. Through advanced digital processing technology, it can identify the exact locations and magnitude of imbalance, allowing for precise corrections. The machine features automated measurement systems that can detect imbalances as small as 0.1 gram-millimeters, ensuring exceptional accuracy in the balancing process. Its applications span across various industries, including automotive manufacturing, power generation, and industrial equipment production. The system incorporates user-friendly interfaces that display real-time data and automated correction suggestions, making it accessible to operators of varying skill levels. Modern armature balancing machines also include safety features such as protective enclosures and emergency stop mechanisms, ensuring safe operation during high-speed testing procedures. The technology employed allows for both static and dynamic balancing, addressing different types of imbalance that might affect rotational performance.