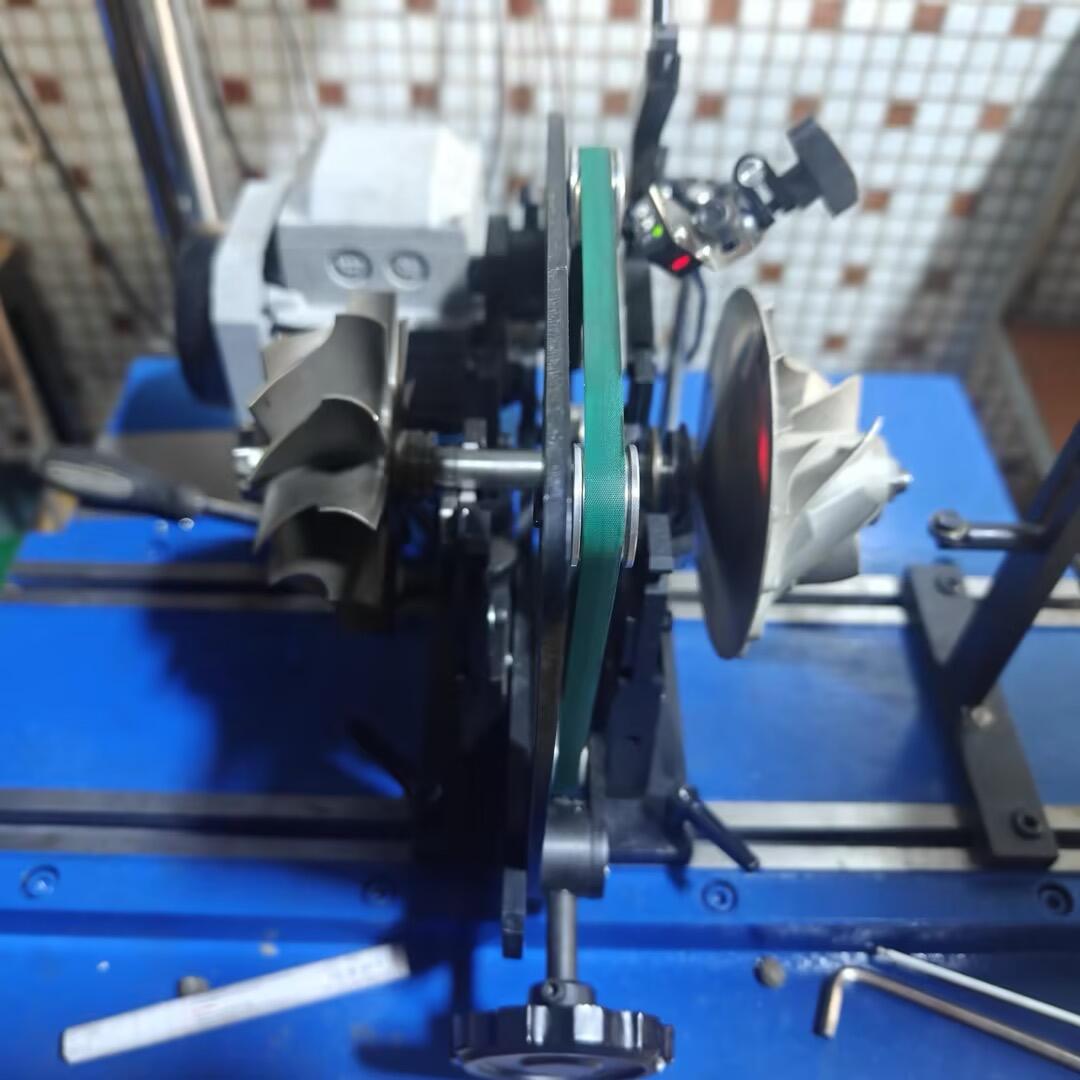

impeller balancing machine for sale

The impeller balancing machine for sale represents cutting-edge technology in rotational equipment maintenance and quality control. This precision instrument is specifically designed to detect and correct imbalances in various types of impellers, ensuring optimal performance and longevity of rotating machinery. The machine utilizes advanced digital sensors and real-time measurement capabilities to identify even minute imbalances that could potentially cause vibration, wear, and reduced efficiency. Operating through a sophisticated combination of mechanical and electronic systems, it can handle impellers of different sizes and weights, making it versatile for various industrial applications. The machine's measurement system includes high-precision sensors that detect both static and dynamic imbalances, while its user-friendly interface allows operators to easily interpret data and make necessary adjustments. Built with industrial-grade components, it ensures reliable operation in demanding manufacturing environments and features automatic calculation of correction weights and positions, significantly reducing the time required for the balancing process. The machine also incorporates safety features such as emergency stops and protective enclosures, ensuring operator safety during the balancing procedure.