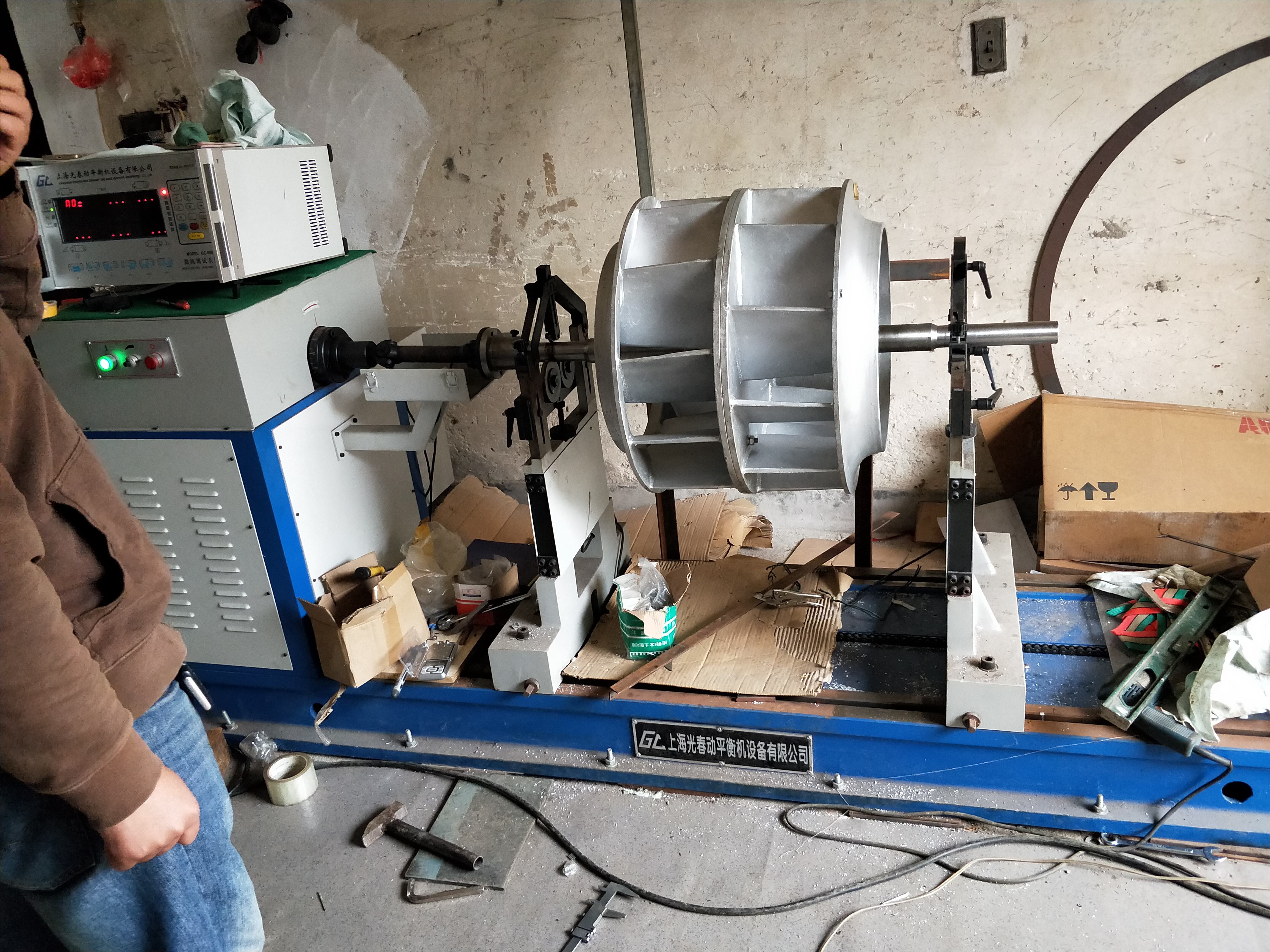

exhaust fan balancing

Exhaust fan balancing is a critical maintenance procedure that ensures optimal performance and longevity of ventilation systems. This precise technical process involves measuring and correcting any uneven weight distribution in the fan's rotating components, particularly the fan wheel and shaft assembly. During the balancing procedure, specialized equipment measures vibration levels at various points while the fan operates at full speed. Technicians use these measurements to determine the location and magnitude of imbalance, then make necessary adjustments by adding or removing weight from specific points on the fan wheel. Modern exhaust fan balancing employs sophisticated digital technology, including vibration analyzers and strobe lights, to achieve precise measurements down to micron levels. The process typically begins with a thorough inspection of the fan assembly, followed by cleaning and assessment of mechanical components. Industrial applications range from manufacturing facilities and commercial kitchens to HVAC systems in large buildings. Proper balancing ensures reduced energy consumption, minimal wear on bearings and other components, and significantly decreased noise levels. This essential maintenance procedure typically needs to be performed periodically, depending on usage patterns and environmental conditions.