fan balancing machine

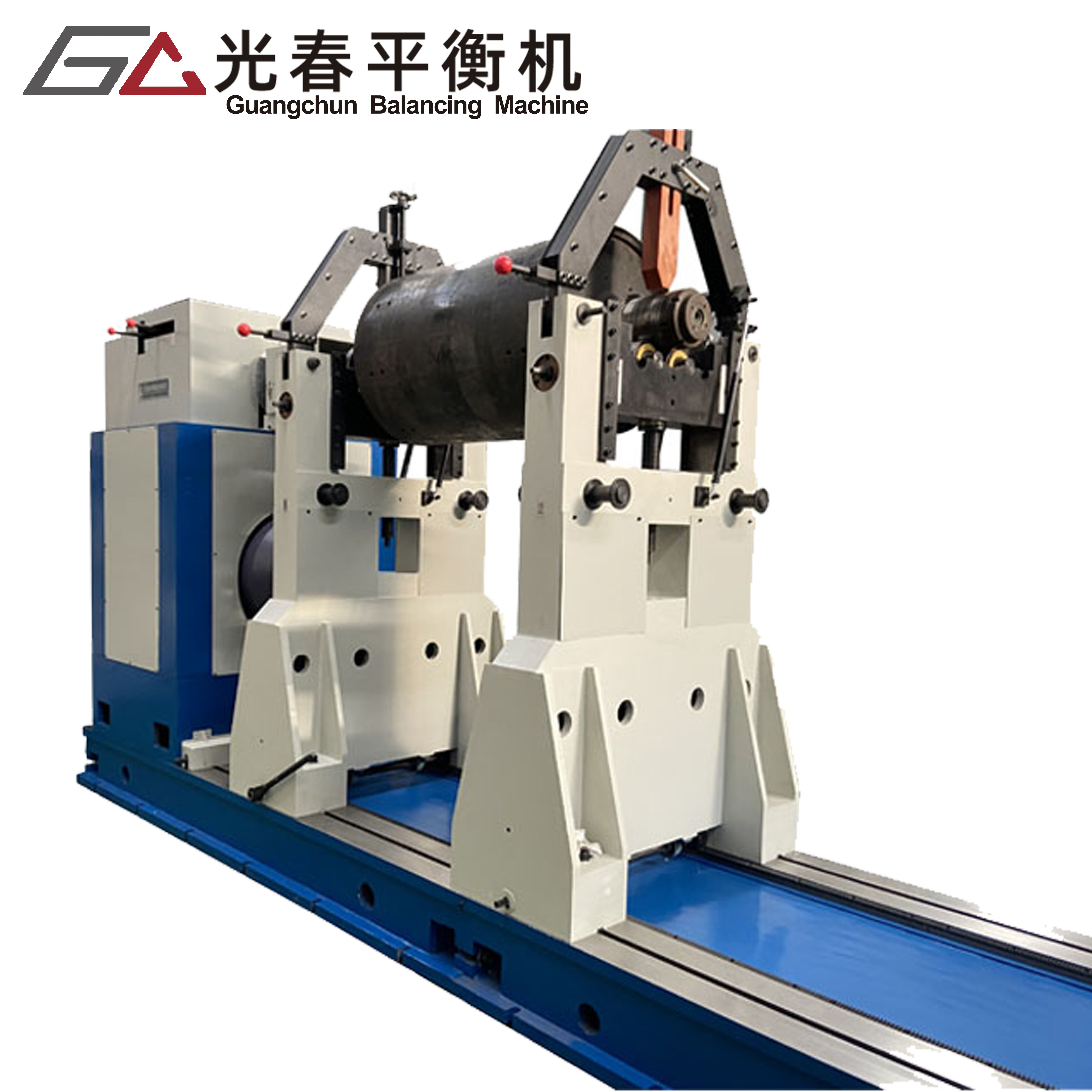

A fan balancing machine is a sophisticated piece of equipment designed to ensure optimal performance and longevity of industrial fans and rotating equipment. This precision instrument detects and corrects imbalances in rotating components, which is crucial for maintaining operational efficiency and preventing premature wear. The machine operates by measuring vibration levels and identifying the exact locations where weight needs to be added or removed to achieve perfect balance. Using advanced sensor technology and computerized analysis systems, it can detect imbalances as small as a fraction of a gram. The machine typically consists of a rigid mounting platform, high-sensitivity sensors, a digital control system, and a user interface that displays real-time data. It can handle various fan types, from small cooling fans to large industrial blowers, making it versatile for different applications. The balancing process involves mounting the fan on the machine's platform, running it at operational speeds, and analyzing the vibration patterns. The system then calculates the precise corrections needed to achieve optimal balance. Modern fan balancing machines often incorporate features like automatic measurement sequences, digital data logging, and report generation capabilities, making the balancing process more efficient and documented.