what is meant by dynamic balance

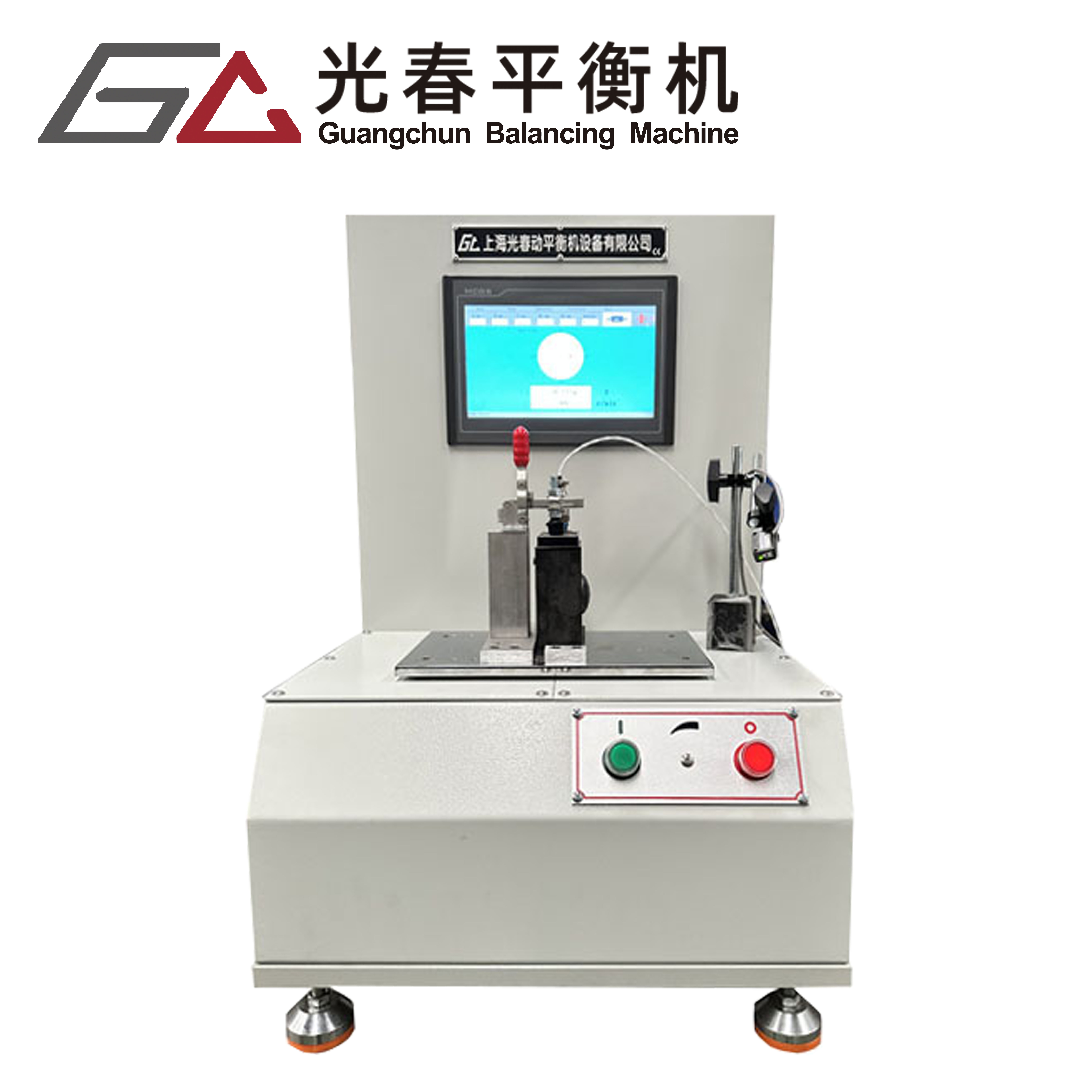

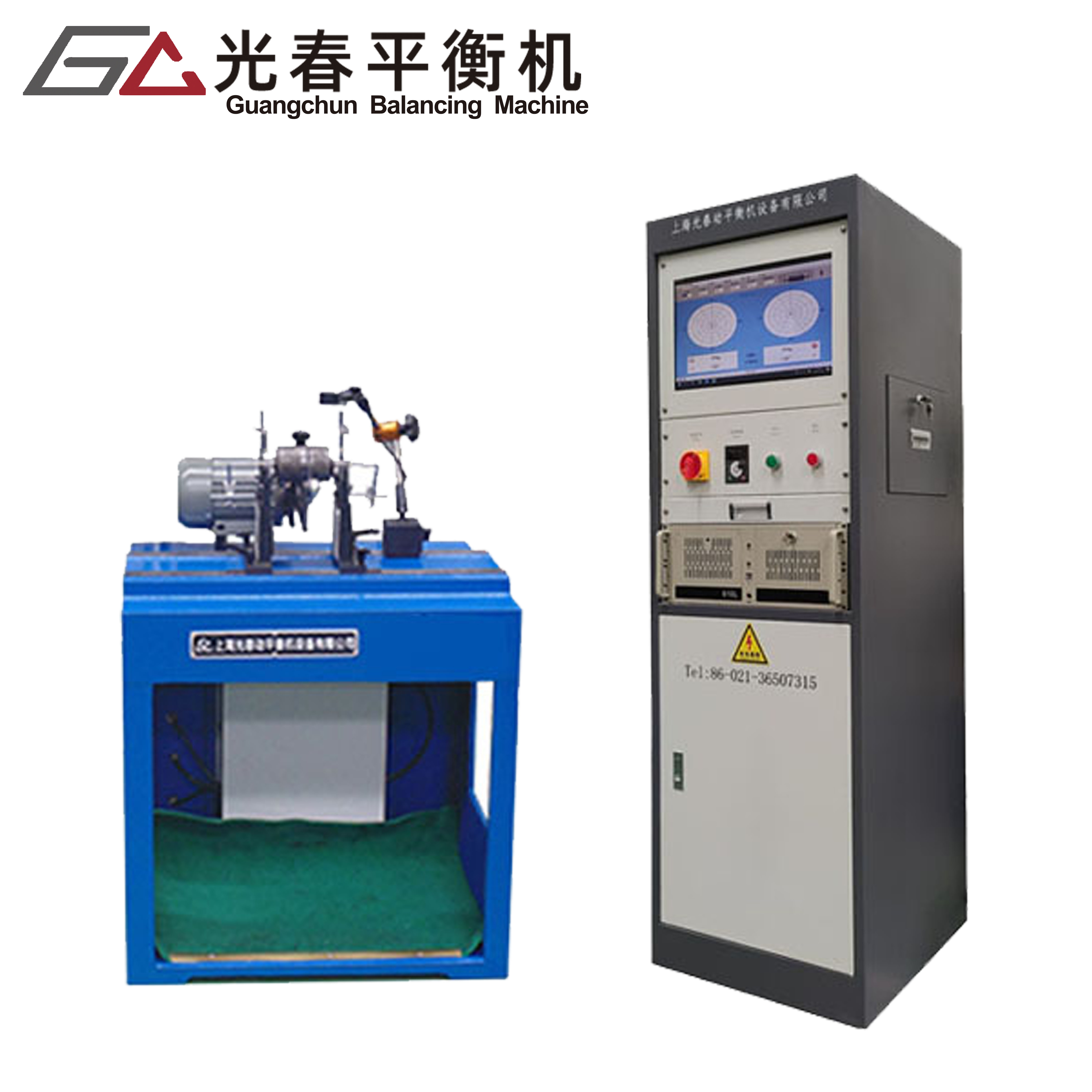

Dynamic balance refers to the state of equilibrium achieved in motion or during movement, representing a crucial concept in various fields including mechanics, sports science, and engineering. This principle involves maintaining stability while an object or system is in motion, unlike static balance which deals with stationary equilibrium. In mechanical systems, dynamic balance ensures that rotating components operate smoothly without unwanted vibrations. The concept encompasses the distribution of mass and forces in such a way that the center of gravity remains stable during movement. Modern technology employs sophisticated sensors and computer systems to measure and maintain dynamic balance in applications ranging from automotive wheel balancing to industrial machinery. The process involves analyzing forces, torques, and moments acting on a system while it's in motion, then making necessary adjustments to achieve optimal performance. Dynamic balance is particularly important in high-speed rotating equipment, where even slight imbalances can cause significant vibration, wear, and potential failure. The principle also applies to biological systems, where organisms maintain balance during movement through complex neuromuscular coordination.