محلل عدم توازن الدوار

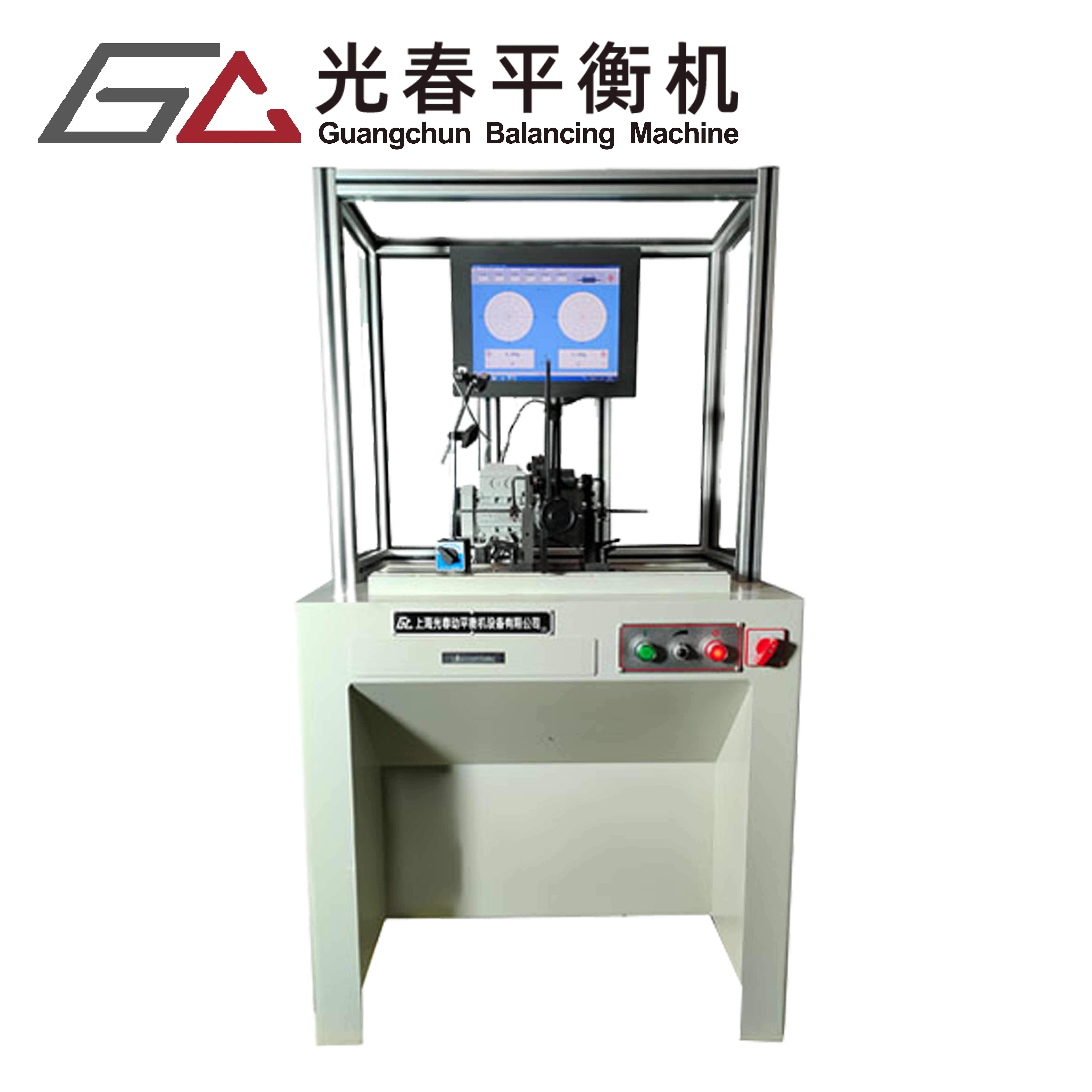

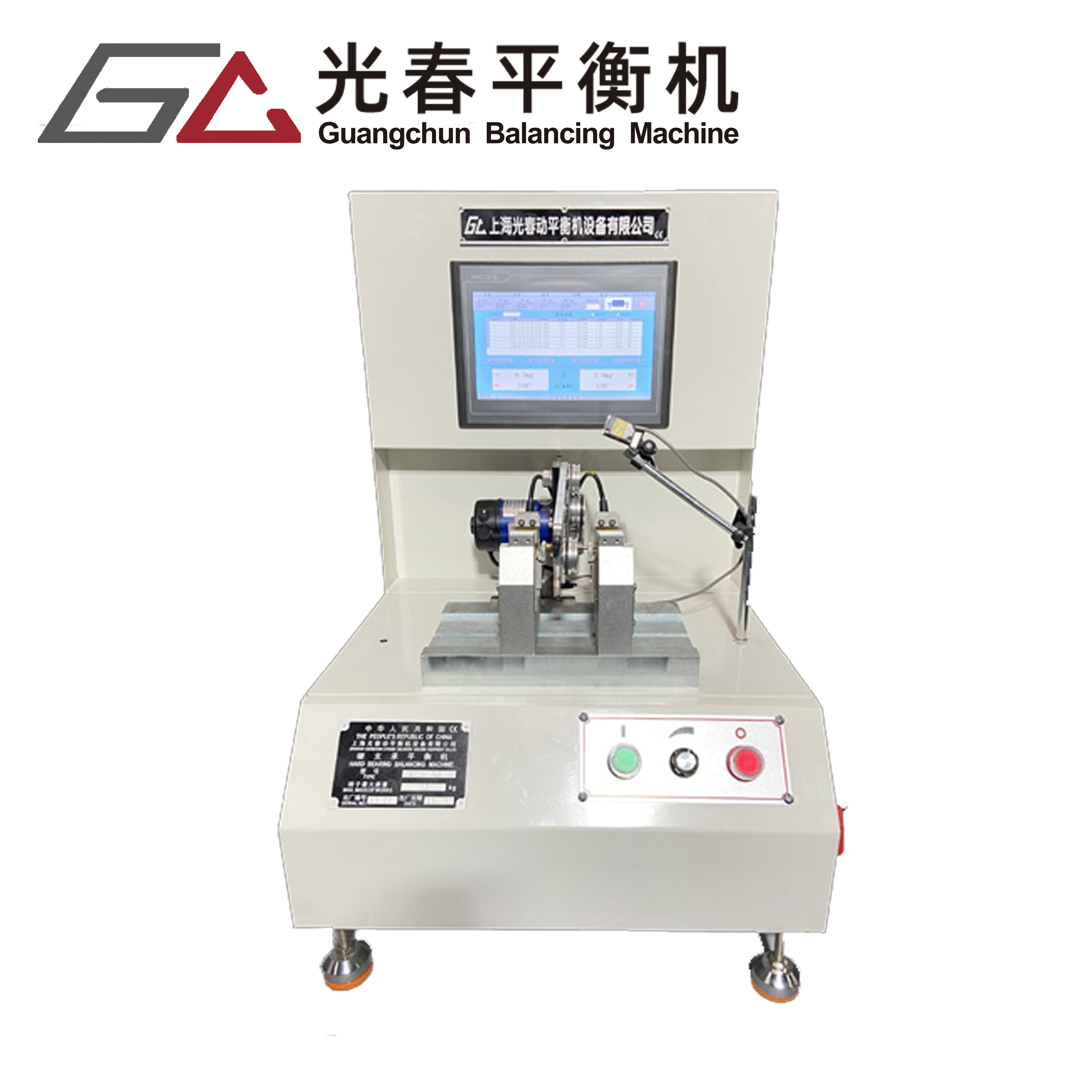

إن محلل عدم توازن الدوار هو جهاز تشخيصي متطور يُصمم لتحديد وقياس حالات عدم التوازن في مكونات الآلات الدوارة. ويستخدم هذا الأداة الأساسية مستشعرات متقدمة وتكنولوجيا معالجة الإشارات الرقمية للكشف عن أنماط الاهتزازات وحساب موقع ومقدار قوى عدم التوازن بدقة. يعمل المحلل من خلال جمع بيانات في الوقت الفعلي أثناء تشغيل الآلة، حيث يقوم بقياس الاهتزازات الشعاعية والمحورية وزوايا الطور وسرعات الدوران. ويمكنه تحديد عدة أنواع من حالات عدم التوازن، بما في ذلك عدم التوازن الثابت وعدم التوازن المتزامن وعدم التوازن الديناميكي. وعادةً ما يتضمن النظام أجهزة استشعار عالية الدقة للتسارع وللسرعة وللإزاحة تعمل بالتعاون مع برامج متخصصة لتوفير تحليل شامل. ويتميز محللات عدم توازن الدوار الحديثة بواجهات سهلة الاستخدام تعرض البيانات عبر تمثيلات بيانية واضحة، مما يسهل على الفنيين تفسير النتائج وإجراء التعديلات اللازمة. وهذه الأدوات ذات قيمة كبيرة في برامج الصيانة الوقائية، حيث تساعد في إطالة عمر المعدات ومنع حدوث أعطال كبرى. وتمتد تطبيقاتها إلى مختلف الصناعات، بما في ذلك إنتاج الطاقة والفضاء والصناعة automotive والصناعات الثقيلة، حيث تلعب المعدات الدوارة دورًا حيويًا في العمليات.