איזון ג'irosקופ לאחר השוק

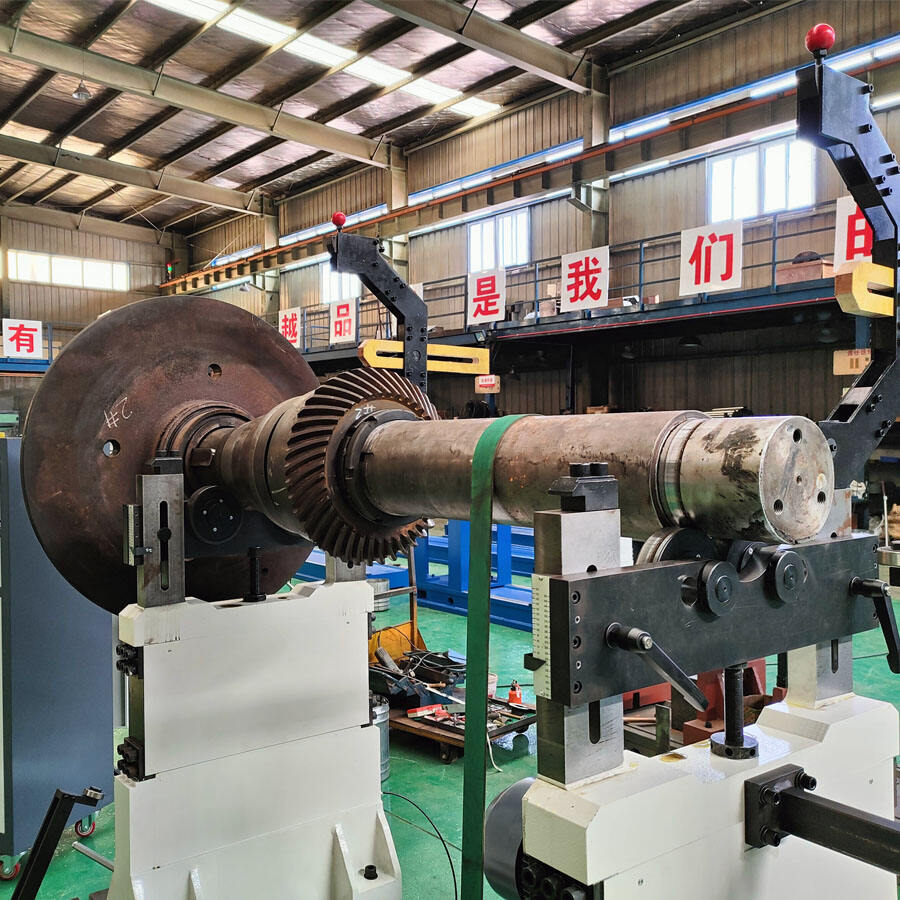

איזון גלגל הנעה הוא תהליך תחזוקה קריטי של הרכב המבטיח ביצועים אופטימליים של המנוע וארוכת החיים. תהליך זה מונע מדויק כרוך בכוון זהיר של חלוקת המשקל של גלגל הנעה כדי לחסל רטטים ולהבטיח תפקוד חלול של המנוע. התהליך משתמש בציוד מאוזן ממוחשב מתקדם כדי לזהות אפילו חוסר איזון מינימלי במערכת הגלגל. במהלך תהליך האיזון, טכנאים מחברים את הגלגל על מכונת איזון מיוחדת שמסתובבת במהירות גבוהה כדי למדוד כל חוסר עקביות במשקל. הציוד מספק קריאות מפורטות של איפה חומר צריך להוסיף או להסיר כדי להשיג איזון מושלם. ההתקדמות הטכנולוגית הזו שינתה את דיוק האיזון של גלגל הנעה, מעבר לשיטות ידניות מסורתיות כדי לספק התאמות מדויקות, מונחות על ידי מחשב. יישומי האיזון של גלגל הנעה בשוק האוטומטי נרחבים למכוניות שונות, ממנהגים יומיומיים למכוניות מירוץ ביצועים גבוהים. זה חיוני במיוחד עבור כלי רכב משופרים עם מערכות מכתש משופרות או אלה שחווים רטטים בקו ההנעה. התהליך כולל גם בדיקה יסודית של דפוסי התלבושות, סדקים או בעיות פוטנציאליות אחרות שיכולות להשפיע על הביצועים.