איך פועל האיזון הדינמי במנועים

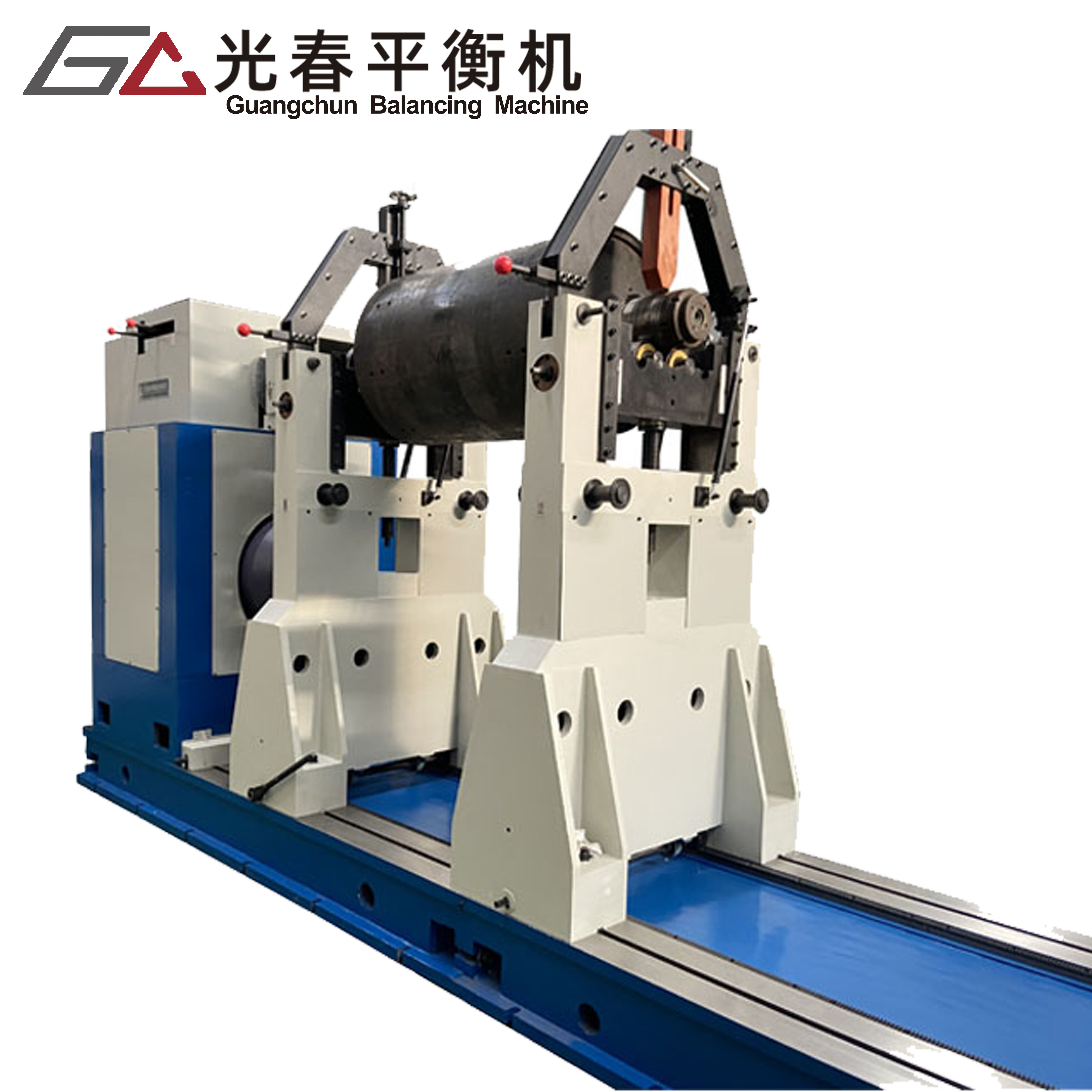

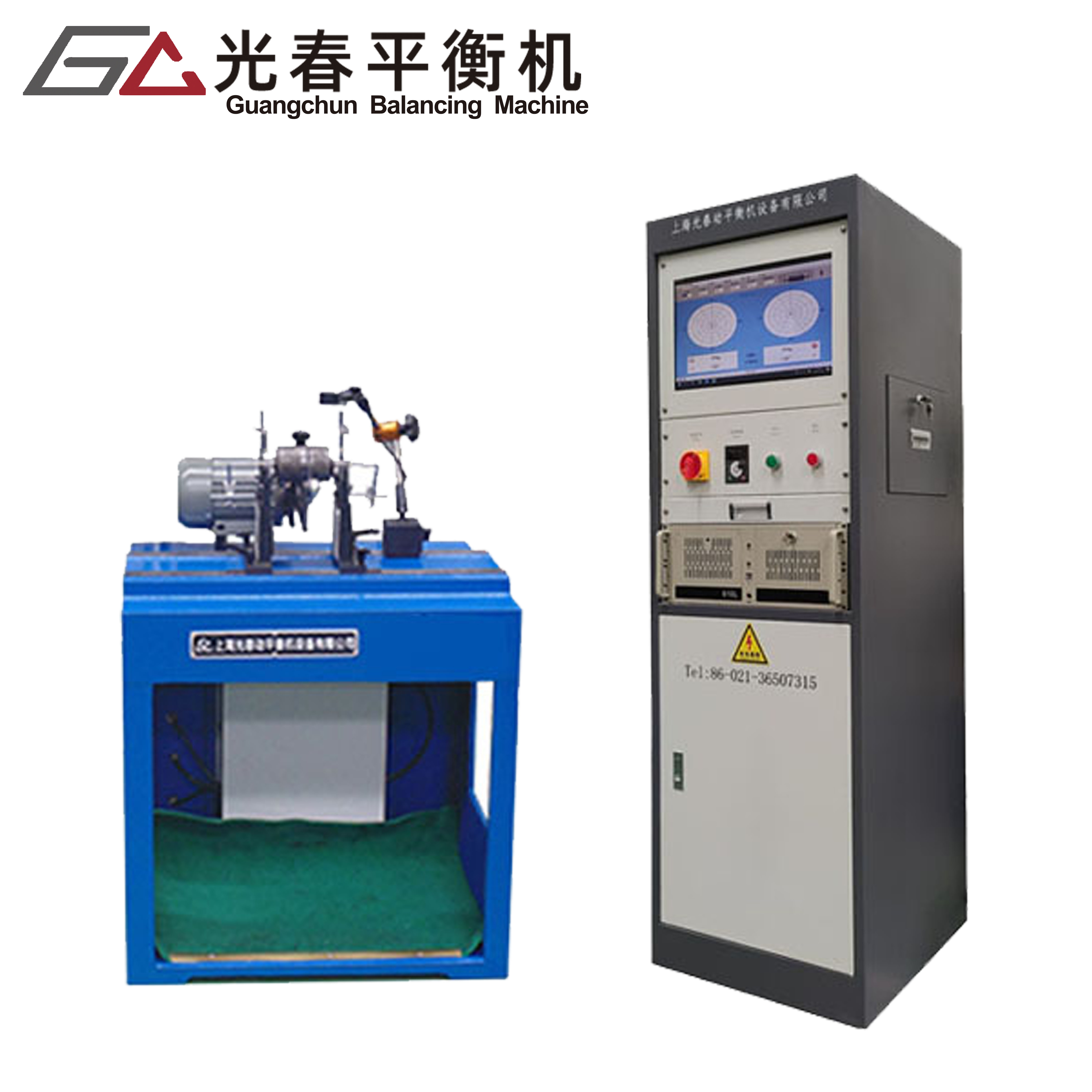

איזון דינמי במנחים הוא תהליך קריטי שמבטיח ביצועים אופטימליים ואריכות ימים של מכונות מסתובבות. טכניקה זו כוללת התפלגות מדויקת של המסה סביב ציר הסיבוב של המנוע כדי לצמצם רעידות ותנודות לא רצויות במהלך הפעלה. התהליך נפתח במדידת התפלגות המשקל סביב הרוטור תוך שימוש במכונות איזון מתקדמות שמסוגלות לגלות גם אי-איזונים זעירים ביותר. המכונות הללו מנתחות את התנהגות הרוטור במהירויות שונות ו מזהות נקודות בהן יש להוסיף או להוריד משקל כדי להשיג איזון מושלם. ביישומים מודרניים, האיזון הדינמי עושה שימוש בсенסורים מתקדמים ובניתוח בעזרת מחשב כדי להשיג מדידות מדויקות עד לרמות של מיקרומטרים. הטכנולוגיה מתחשבת הן באי-איזון סטטי (במישור אחד) והן באי-איזון צמוד (בשני מישורים), תוך התייחסות לדינמיקות סיבוב מורכבות שמתרחשות במהירויות גבוהות. מצב מאוזן זה הוא חיוני עבור מנועים תעשייתיים, שכן הוא מונע wearing מוגזם של השעיות, מצמצם רמות של רעש ומבטיח העברת כוח יעילת. התהליך כולל לרוב מספר חזרות של בדיקה והתאמות עד להשגת רמת האיזון הרצויה, בהתאם לסטנדרטים בינלאומיים כמו ISO 1940-1.