ძრავის დინამიური ბალანსირება

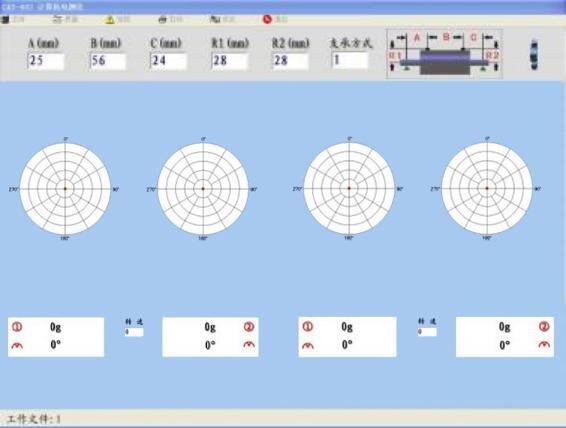

Მოტორის დინამიური ბალანსირება მექანიკური ინჟინერიის გადამწყვეტი პროცესაა, რომელიც უზრუნველყოფს ბრუნვითი მოწყობილობების ოპტიმალურ მუშაობას და ხანგრძლივობას. ამ რთულ პროცედურაში შედის ბრუნვითი კომპონენტების წონის განაწილების გაზომვა და სწორედა იმ წონის გასწორება, რათა ამოიღოს ვიბრაცია და უზრუნველყოს გლუვი მუშაობა. პროცესი იყენებს დახვეწილ ელექტრონულ მოწყობილობებს იმ სიჩქარეებზე წონაგდებების გასაზომად, რომლებიც შეიძლება მოტორის მუშაობაზე გავლენას ახდენდეს, როგორც სტატიკური, ასევე წყვილის წონაგდებების გაზომვით. ბალანსირების პროცედურის დროს სპეციალური სენსორები ამჩნევს წონაგდების სიდიდეს და ადგილს, ხოლო კომპიუტერული სისტემები ანალიზის მეშვეობით განსაზღვრავს სწორი წონის პარამეტრებს და მდებარეობას. ეს ტექნოლოგია ეხება სხვადასხვა ტიპის მოტორებს, პატარა ზუსტი ხელსაწყოებიდან დიდი სამრეწველო მოტორებამდე, რათა უზრუნველყოს თითოეულის მაქსიმალური ეფექტუანობით მუშაობა. ამჟამინდელი დინამიური ბალანსირების სისტემები შეუძლია ამოიცნონ წონაგდებები მხოლოდ წილადი გრამის სიზუსტით, რაც მათ აუცილებელ ხდის საჰაერო-სივრცული, ავტომობილის წარმოებისა და ელექტროენერგიის წარმოების სფეროებში მაღალი სიზუსტის მომთხოვნი აპლიკაციებისთვის. პროცესი არ ეხება მხოლოდ არსებულ წონაგდებებს, არამედ ასაცილებს შესაძლო პრობლემებს, რომლებიც შეიძლება წარმოიშვას მოწყობილობის მუშაობისას დამსხვრევის შედეგად.