динамикалык тең салмактуу машиналар

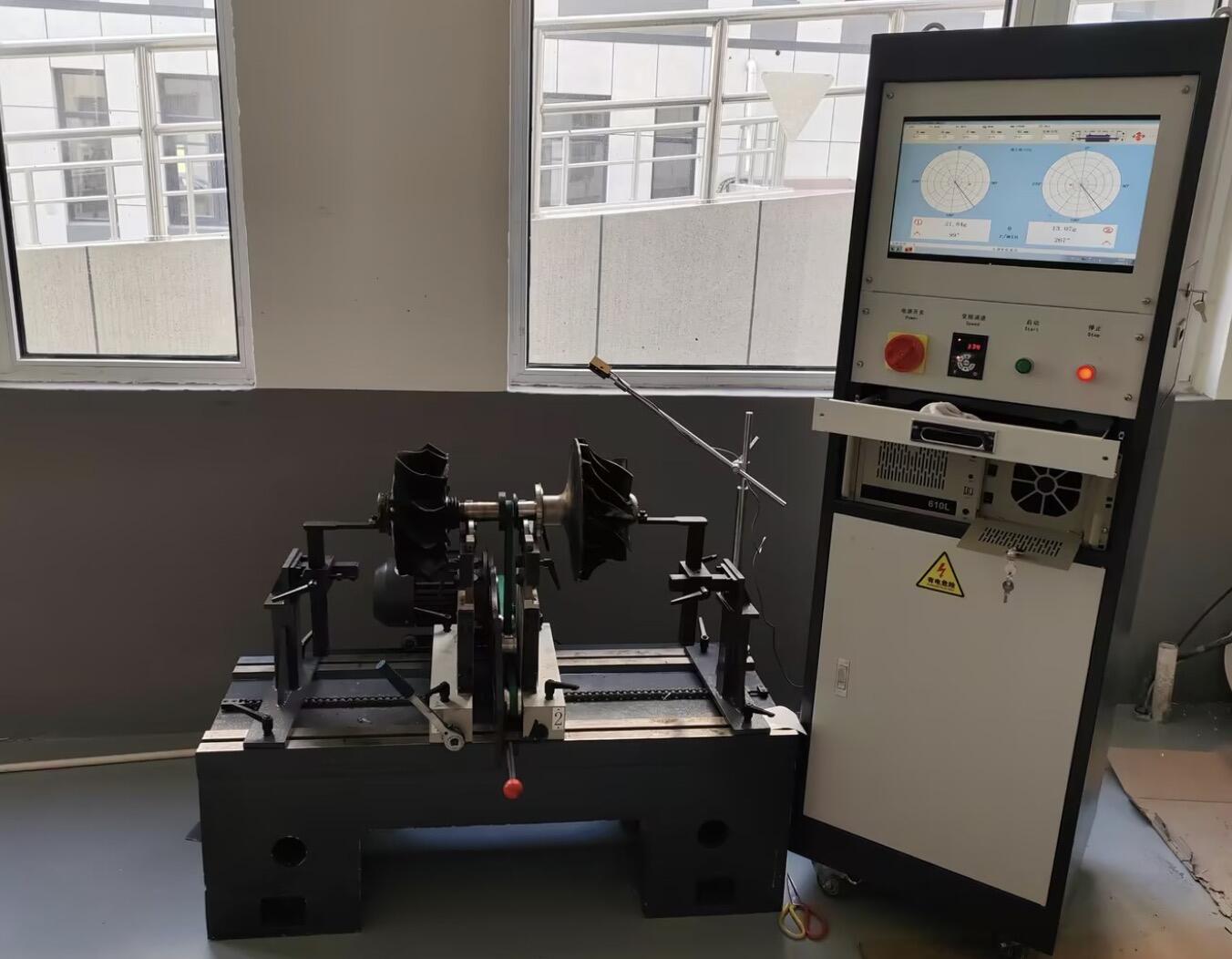

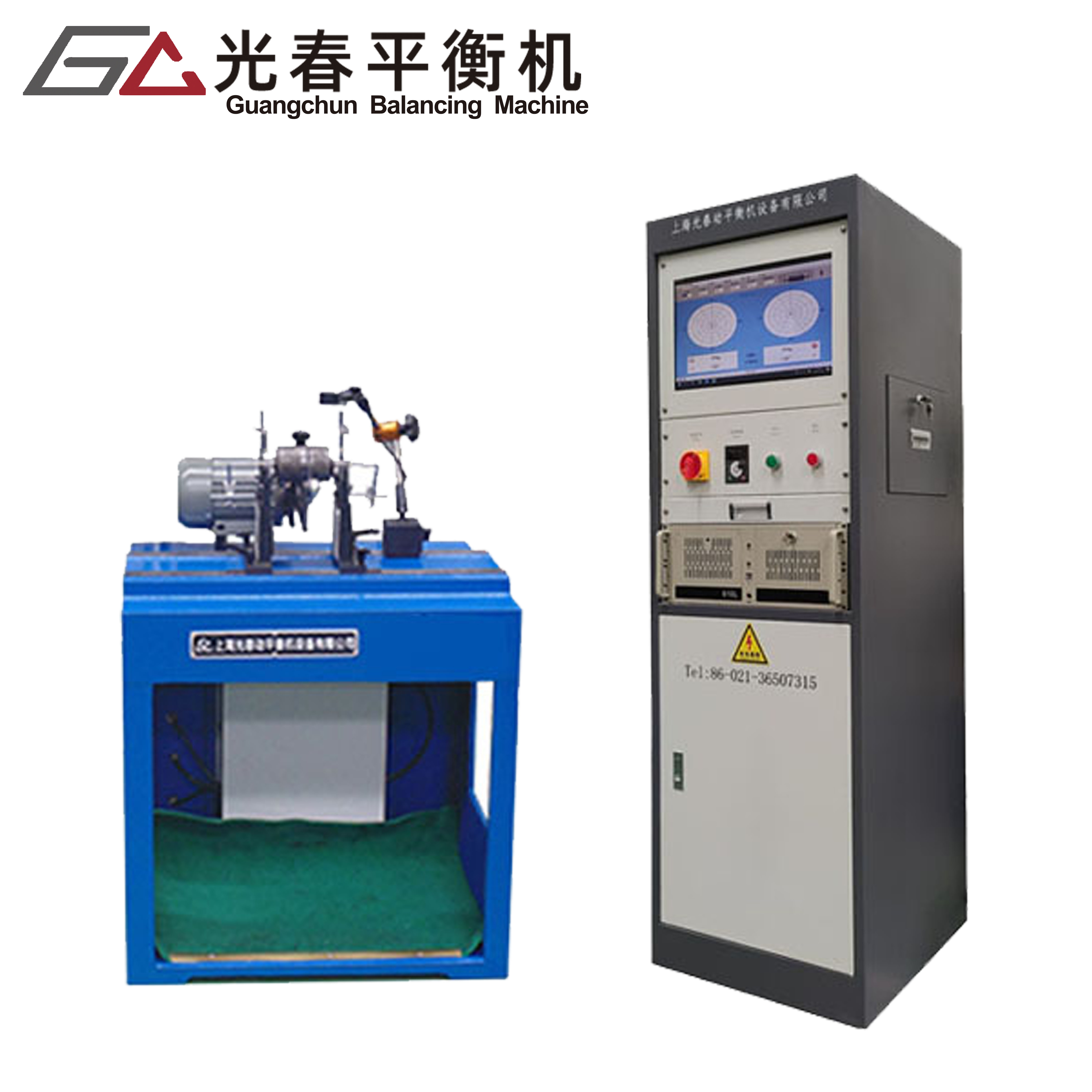

Динамикалык тең салмактоо машиналары – айлану огуштарындагы теңсиздиктерди аныктоого жана түзөтүүгө максатталган күрөлдүү так аспаптар. Бул машиналар айлануучу өстүнүн айналасында массанын таралышын өлчөп, салмак бирдей таралбаган жерлерди аныктайт. Ири тез дабдыл алгычтар менен компьютердик анализ системаларын колдонуп, вибрацияга, истешилге жана техника чыгышына алып келетин минималдуу теңсиздикти да аныкташат. Технология иштетүү талаптарына ылайык катуу же жумшак орнотулган системаларды колдонот. Заманбап динамикалык тең салмактоо машиналары ювелир цифдик экрандарын, автоматташтырылган өлчөө процесстерин жана насыя убакытта маалыматты анализдоо мүмкүнчүлүктөрүн камтыйт. Автомобил, авиация, электр энергиясы генерациялоо жана өнөр жай техникалары сыяктуу бир нече индустрияларда өндүрүш жана техникалык кызмат көрсөтүү операцияларында пайдаланылат. Машиналар кичинекей турбиндерден баштап чоң өнөр жай шахматтарына чейинки бөлүктөргө иштей алышы мүмкүн, бир жазылуу жана эки жазылуу тең салмактоо операцияларында так өлчөмдөрдү сунуш кылат. Программалоочу софттон пайдалануу деталдуу долбоордоолорду, маалыматты сактоону жана тенденцияны анализдоону мүмкүн кылат, ал эми превентивдүү техникалык кызмат көрсөтүү стратегияларын жана сапаттын баскычын белгиленүүнү камтыйт. Бул машиналар техниканын узак мерзимдүү иштешине, техникалык кызмат көрсөтүүнүн чыгымдарын кемитүүгө жана айлануучу техникалардын оптималдуу иштөөсүнө чоң салым берет.