machina aequiponderandi bini plane

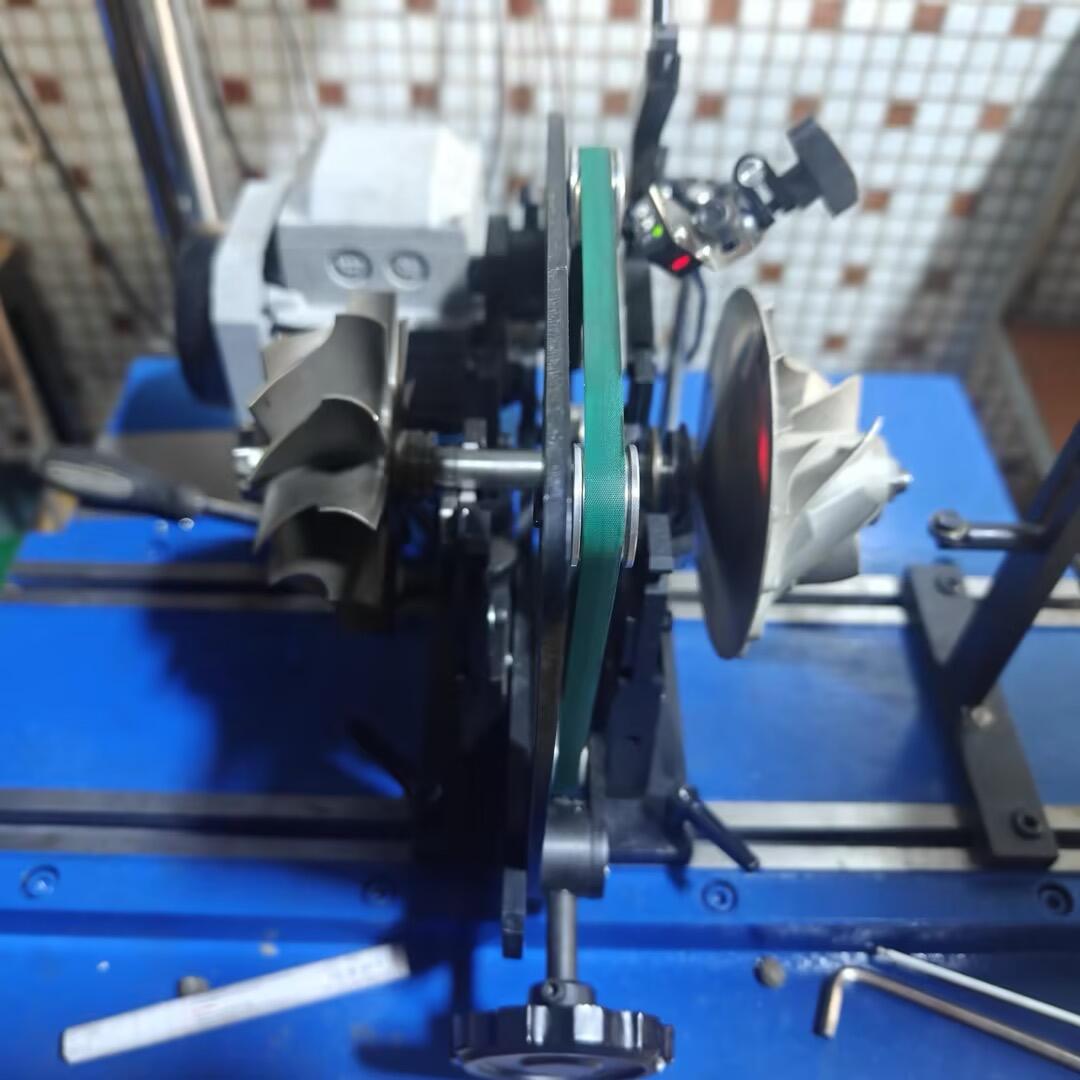

Machina aequilibratūrae bīplānāris est instrumentum subtile ad imballantias in componentibus rotatorīs simul in duō planīs agnoscendās et corrigendās. Hic apparatus praecīsiōnem sensorum atque analysim computatricem adhibet ad mensurandos pulsatūrārum modōs ac locum et quantitātem imballantiārum tam in planō axiāle quam radialem determinandam. Machina operatur dum opus vertitur celeritātibus dēfinītīs dum data per plūrima puncta sensoria colliguntur, analysim completam de imballantiā dynamicā offerens. Caracteristici necessariae includunt capacitātem mensurae altā praecīsiōnis, calculatiōnem automāticam ponderum correctīvōrum, et monitoring systemata realis temporis. Haec technologia praecipue utilis est in ūniversis ut manufactūra automobilōrum, componentibus aerospātiālibus, machināriō industriae, et instrumentīs generandi potestātem. Facultās machinae ad varia magnitūdinum et pondĕrum componentium tractandas, una cum interfacie amicā usōri, eam in instrumentum nesciōndum pro controlā et manutentōne efficit. Machinae modernae aequilibratūrae bīplānāris systemata digitālia regulentur et calibrātiōnem automāticam includunt, praestandōm constans praecīsiōnem fidemque in rēsultātīs mensurae. Hi apparatus necesse sunt ad praestāntiam et longevitātem machināriī rotatorii servandās, quod aequilibrātiō prōpria vībrātiōnem minuit, lābōrem diminuit, et efficaciam operativam optimizat.