тэнцвэржүүлэх машины үйлдвэрлэгчид

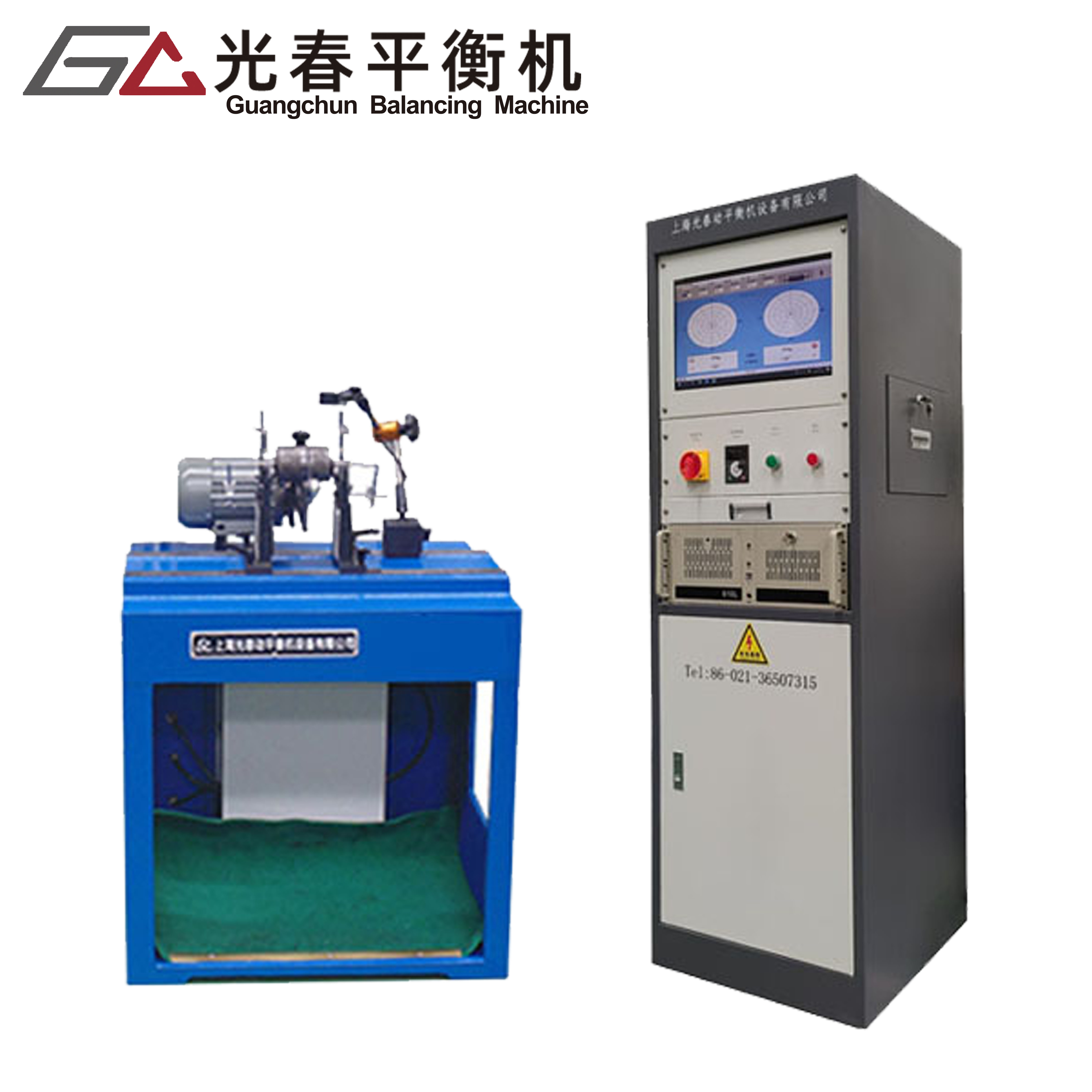

Тэнцвэржүүлэх машины үйлдвэрлэгчид нь инженерийн нарийн төвөгтэй байдал, олон салбарын үйлдвэрлэлийн чанарыг хангахад чухал үүрэг гүйцэтгэдэг. Эдгээр үйлдвэрлэгчид эргэдэг деталян доторхи тэнцвэргүй байдлыг илрүүлж засварлах боломжтой, нарийн төвөгтэй тоног төхөөрөмжүүдийг хөгжүүлдэг. Тэдний бүтээгдэхүүн нь өндөр нарийн мэдрэгчид, бодит цагийн хяналтын системүүд, нарийн тохируулах механизмтай хангагдсан байдаг. Орчин үеийн тэнцвэржүүлэх машинууд нь ажиллуулах хугацааг болон хүний алдааг резко бууруулах зорилготой, цифров хяналтын систем, хэрэглэгчид дөхөмтэй интерфейс, автоматаар засварлах процессыг агуулдаг. Мөн эдгээр үйлдвэрлэгчид горизонтал ба вертикаль тэнцвэржүүлэх системүүдийг санал болгодог бөгөөд хэдэн граммаас хэдэн тонн хүртэлх деталуудтай ажиллах чадвартай. Ашиглагдаж буй технологи нь олон төрлийн вибрацийг шинжлэх боломжийг олгох бөгөөд статик болон динамик тэнцвэржүүлэх функцийг агуулдаг. Солонгосын уран ухаантай үйлдвэрлэгчид Industry 4.0-ийн онцлог шинж чанаруудыг нэвтрүүлдэг: холоос хянах, мэдээлэл бичих, урьдчилан таамаглах техникийн сервисийн боломжуудыг оруулж ирснээр тэдний бүтээгдэхүүн нь ирээдүйтэй, үр ашигтай болсон юм. Тэд мөн автомашин, агаарын тээвэр, цахилгаан энергийн үйлдвэрлэл, ерөнхий үйлдвэрлэлийн салбарт зориулсан захиалгат шийдлүүдийг мөн санал болгодог.