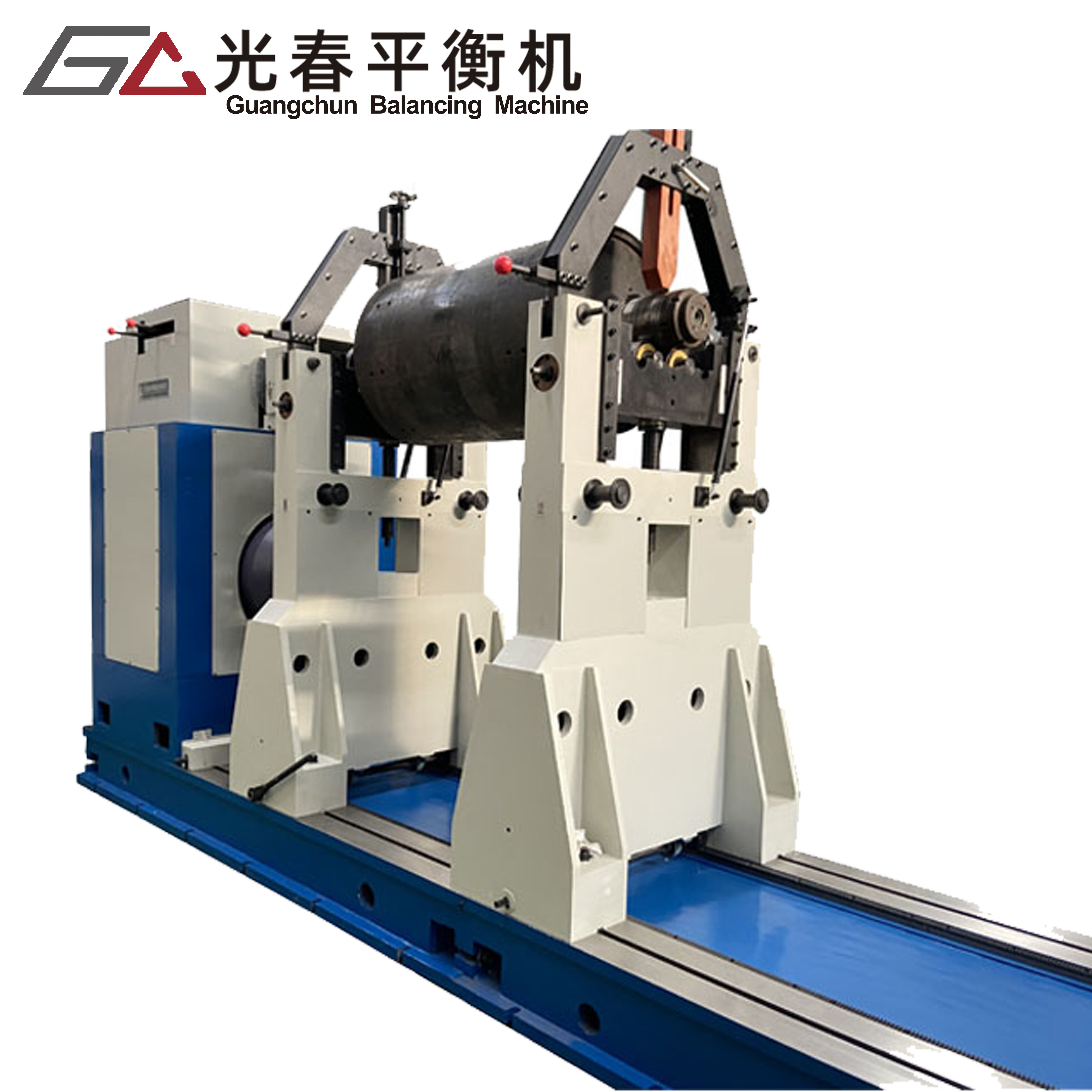

elektrik motorları için dengeleme makinesi

Elektrik motorları için dengeleme makinesi, motor bileşenlerinin optimal performansını ve ömrünü sağlamak amacıyla tasarlanmış karmaşık bir ekipmandır. Bu hassas cihaz, özellikle rotorlar ve armatürler gibi dönen parçalardaki denge bozukluklarını ölçerek düzeltir; bu da sorunsuz çalışmayı sürdürmek ve erken aşınmayı önlemek açısından hayati öneme sahiptir. Makine, motor performansını etkileyebilecek en küçük titreşimleri ve ağırlık farklılıklarını tespit edebilen gelişmiş sensörler ve bilgisayarlı analiz sistemleri kullanmaktadır. Hem statik hem de dinamik dengeleme prensipleriyle çalışan bu sistem, birden fazla düzlemdeki denge bozukluklarını belirleyebilir ve doğru düzeltme önerileri sunar. Teknolojisi, 0,0001 gram-inç büyüklüğündeki denge bozukluklarını bile tespit edebilen yüksek çözünürlüklü ölçüm yeteneğine sahiptir ve böylece dengeleme sürecinde olağanüstü bir doğruluk sağlar. Modern dengeleme makineleri, kullanıcı dostu arayüzler, gerçek zamanlı veri görüntüleme, düzeltme ağırlıklarının otomatik olarak hesaplanması ve ideal dengeyi elde etmek için pozisyon önerileri gibi özellikleri bünyesinde barındırır. Bu makineler, üretim ve bakım operasyonlarında, özellikle motor güvenilirliğinin kritik olduğu otomotivden endüstriyel üretime kadar birçok sektörde hayati rol oynar. Farklı boyutlardaki motorlarla birlikte çalışabilme yeteneği, otomatik kalibrasyon ve kendini tanıma (self-diagnostic) özelliklerine sahip olması nedeniyle bu sistem, elektrik motoru üretiminde kalite kontrol ve performans optimizasyonu için vazgeçilmez bir araçtır.