iki düzlemli dengeleme makinesi

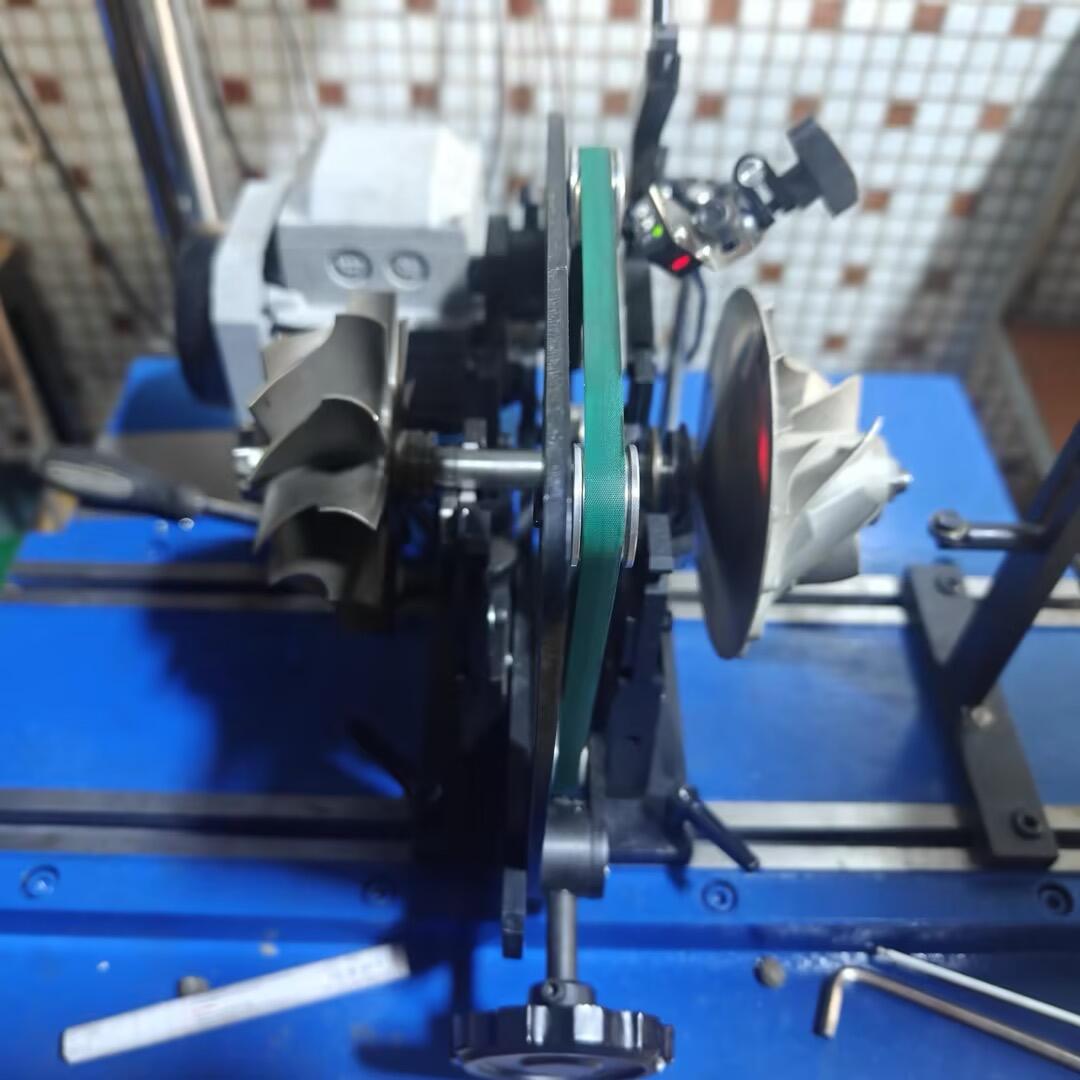

İki düzlemli dengeleme makinesi, dönen bileşenlerdeki dengesizlikleri iki düzlem boyunca aynı anda tespit edecek ve düzeltecek şekilde tasarlanmış ileri teknolojiye sahip bir ekipmandır. Bu gelişmiş makine, hassas sensörler ve bilgisayarlı analiz sistemleri kullanarak titreşim paternlerini ölçer ve hem eksenel hem de radyal düzlemdeki dengesizliğin konumunu ve büyüklüğünü belirler. Makine, iş parçasını belirli hızlarda döndürerek verileri çoklu algılama noktalarından toplamak suretiyle dinamik dengesizliğin kapsamlı bir analizini sağlar. Temel özellikleri arasında yüksek hassasiyetli ölçüm yetenekleri, otomatik düzeltme ağırlıklarının hesaplanması ve gerçek zamanlı izleme sistemleri yer alır. Bu teknoloji özellikle otomotiv imalatı, havacılık ve uzay bileşenleri, endüstriyel makinerya ve enerji üretimi ekipmanları gibi sektörlerde büyük değer taşımaktadır. Farklı boyut ve ağırlıklardaki bileşenlerle çalışabilme kabiliyeti ile kullanıcı dostu arayüzü sayesinde kalite kontrol ve bakım operasyonları için vazgeçilmez bir araçtır. Modern iki düzlemli dengeleme makineleri, gelişmiş dijital kontroller ve otomatik kalibrasyon sistemlerini bünyesinde barındırarak ölçüm sonuçlarında sürekli doğruluk ve güvenilirliği garanti altına alır. Bu makineler, döner ekipmanların performansını ve ömrünü korumada hayati rol oynar; çünkü uygun dengeleme işlemi, titreşimi azaltmakta, aşınmayı en aza indirgemekte ve operasyonel verimliliği optimize etmektedir.