crankshaft balancing

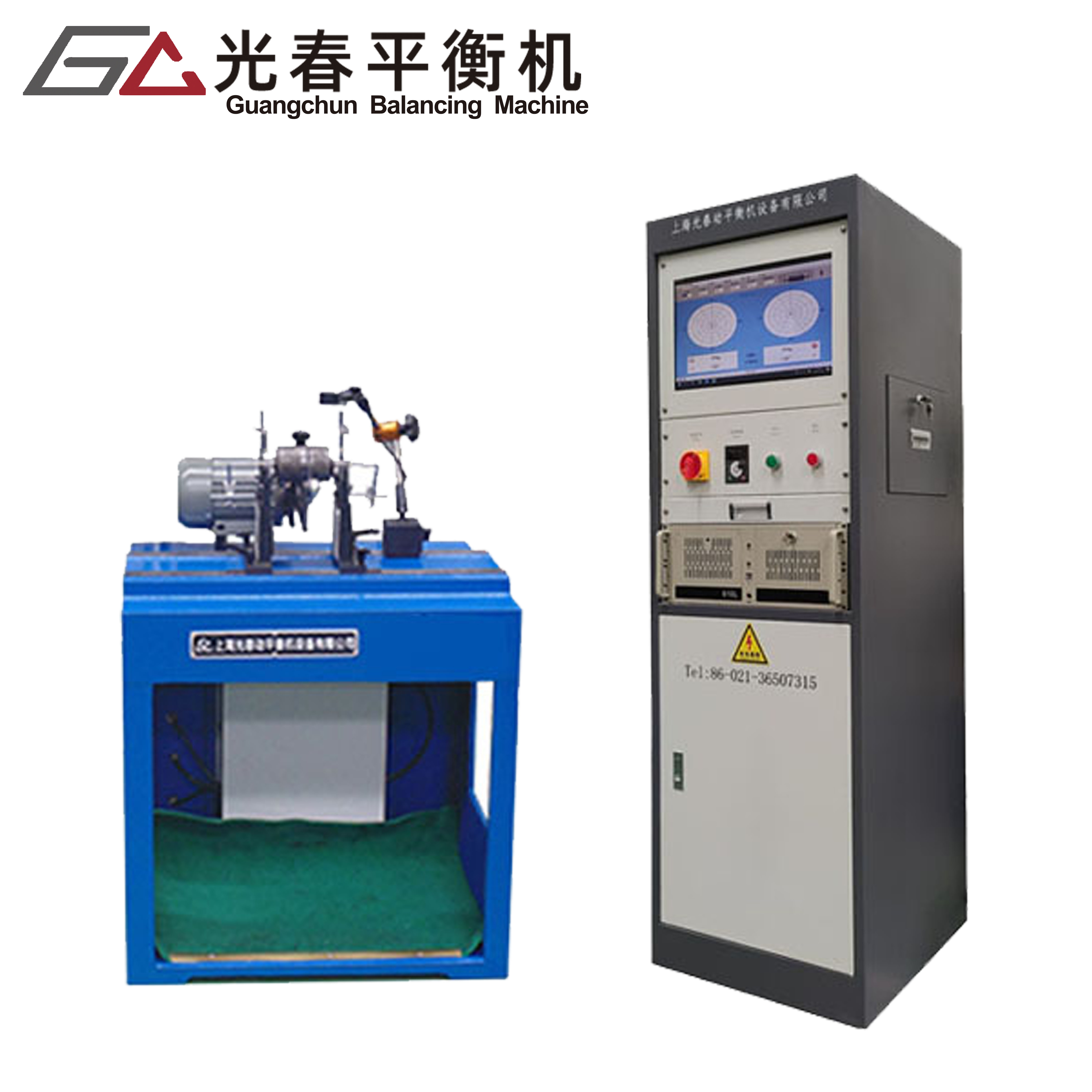

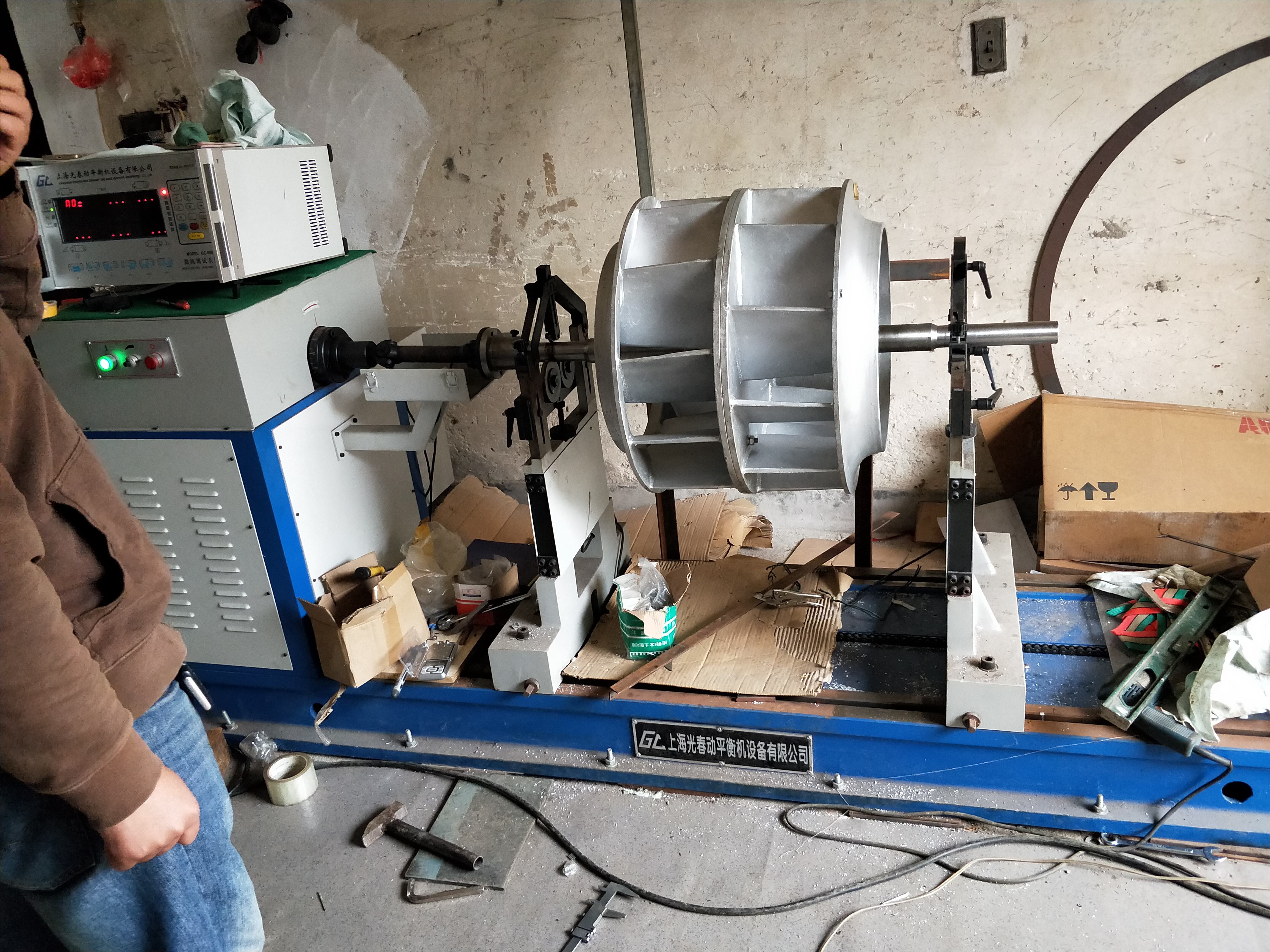

Crankshaft balancing is a critical process in engine manufacturing and maintenance that ensures optimal performance and longevity of internal combustion engines. This precision engineering procedure involves the careful measurement and adjustment of the crankshaft's weight distribution to minimize vibration and wear during engine operation. The process utilizes advanced computerized equipment to identify imbalances in both the rotating and reciprocating masses of the crankshaft assembly. During balancing, technicians measure the crankshaft at various points while it spins at high speeds, detecting even minute irregularities that could cause harmful vibrations. The process typically involves adding or removing material from specific locations on the crankshaft counterweights to achieve the desired balance. Modern crankshaft balancing technology can achieve precision levels within fractions of a gram, ensuring smooth engine operation across all RPM ranges. This technical procedure is essential for high-performance engines, racing applications, and standard vehicle maintenance, as it directly impacts engine smoothness, power output, and component longevity. The process also considers both static and dynamic balancing factors, ensuring comprehensive optimization of the crankshaft's rotational characteristics.