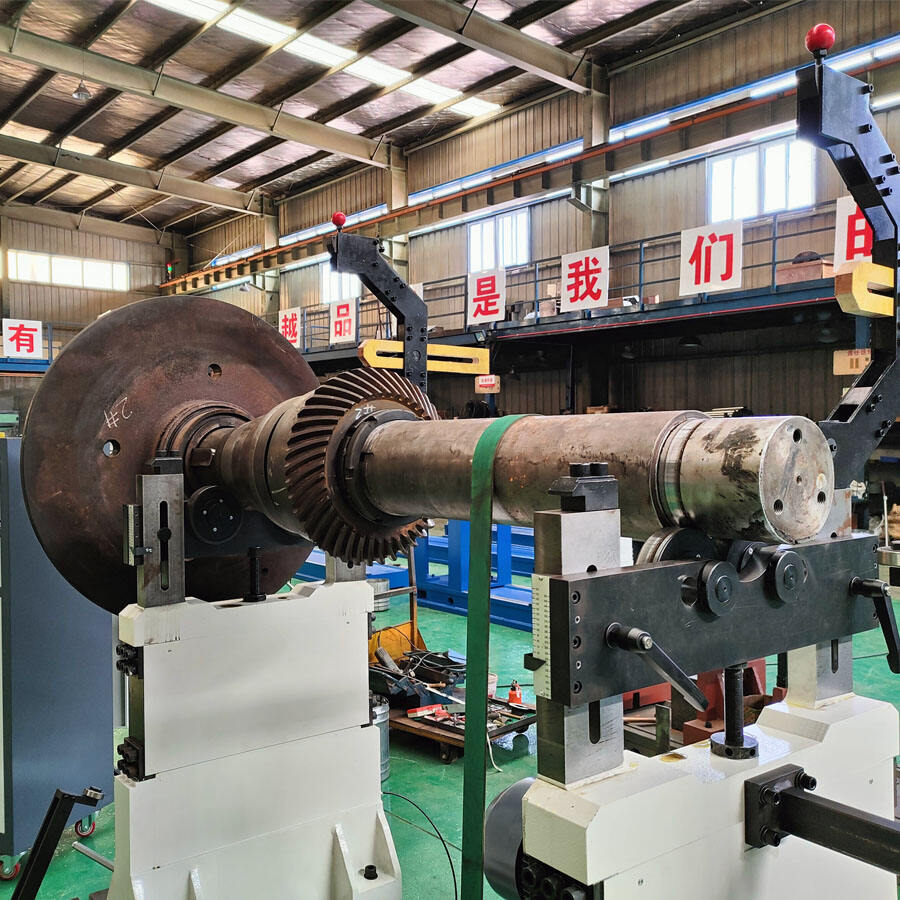

precision crankshaft

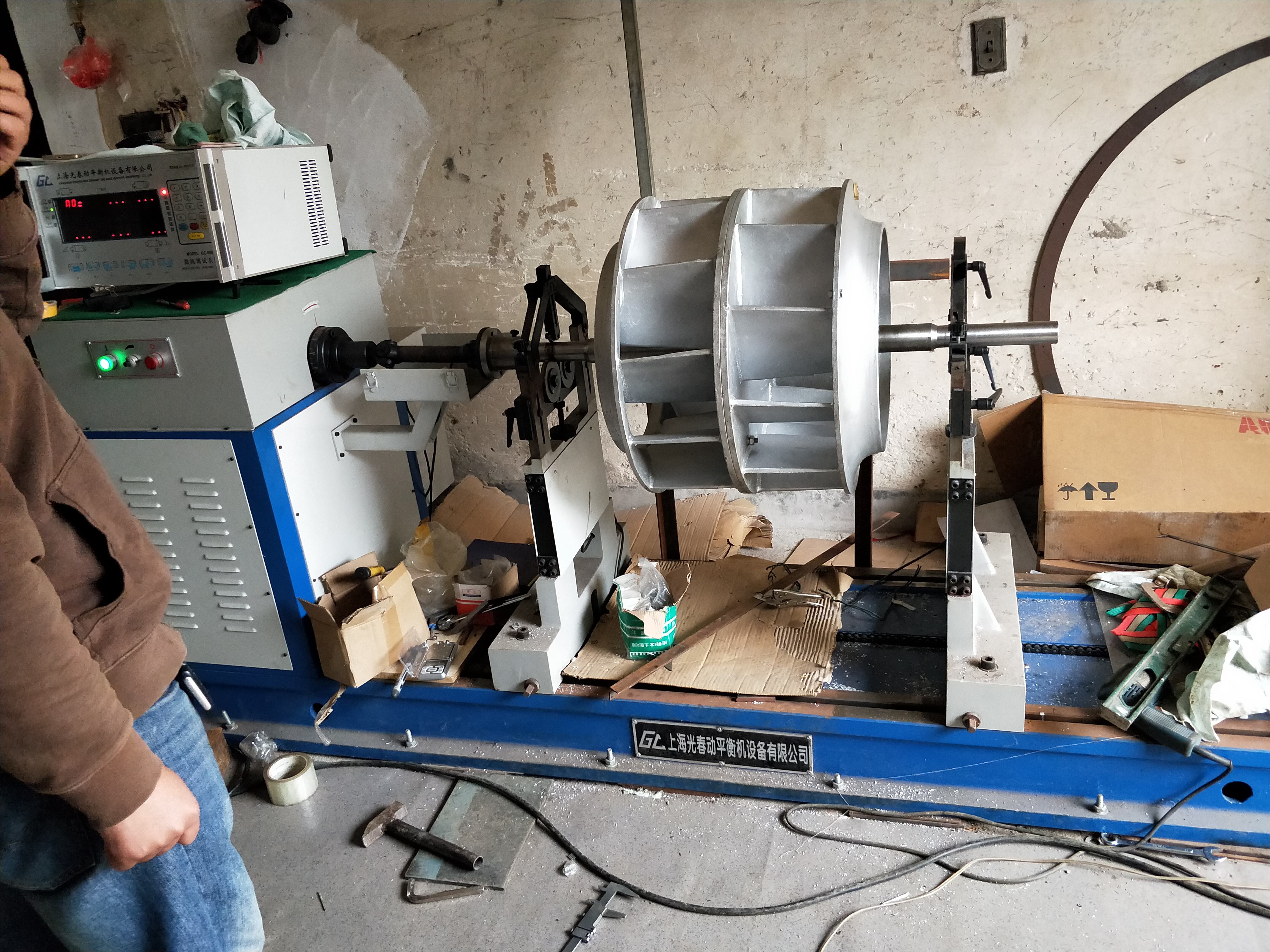

A precision crankshaft represents a masterpiece of engineering excellence, serving as the backbone of modern engine performance. This critical component transforms linear piston motion into rotational force, enabling the efficient operation of internal combustion engines. Manufactured through advanced metallurgical processes and cutting-edge machining techniques, precision crankshafts are designed to exacting tolerances, typically within microns. The construction involves high-grade steel alloys, subjected to specialized heat treatment and surface hardening processes to ensure optimal durability and performance. Modern precision crankshafts feature carefully engineered counterweights, precisely balanced journals, and optimized oil passages for superior lubrication. These components undergo rigorous quality control measures, including advanced non-destructive testing methods and computerized balance checking. The applications span across various industries, from high-performance automotive engines to industrial machinery and marine applications. The design incorporates sophisticated finite element analysis to optimize stress distribution and minimize vibration, resulting in smoother operation and extended engine life. Precision crankshafts also feature advanced surface treatments and coatings that enhance wear resistance and reduce friction, contributing to improved fuel efficiency and reduced emissions.