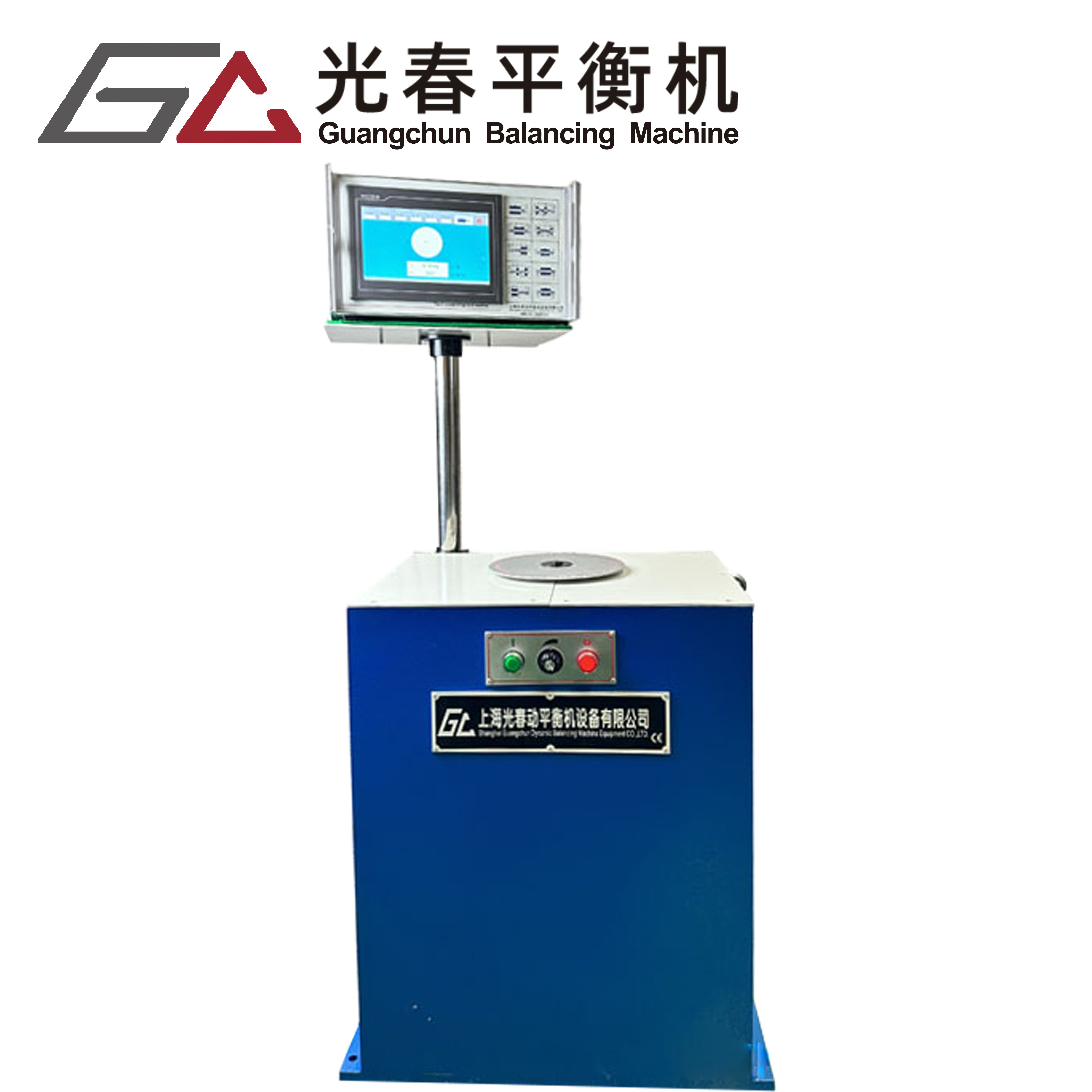

crankshaft balancing machines

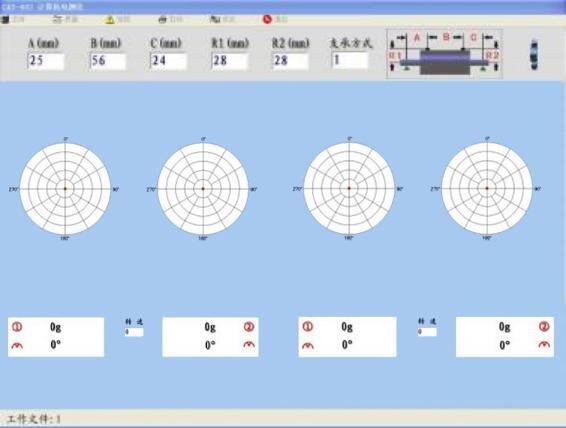

Crankshaft balancing machines are sophisticated precision instruments designed to detect and correct imbalances in automotive and industrial crankshafts. These machines utilize advanced sensing technology and computerized measurement systems to identify weight disparities that could cause harmful vibrations during operation. The machine operates by rotating the crankshaft at specific speeds while sensitive sensors measure the amplitude and phase of vibration at various points. This data is then processed by integrated software that calculates the exact locations where weight needs to be added or removed to achieve optimal balance. Modern crankshaft balancing machines feature automated measuring processes, digital displays, and precise correction recommendations. They can handle crankshafts of various sizes, from small automotive engines to large industrial machinery. These machines typically include features such as automatic calibration, real-time measurement display, and detailed reporting capabilities. The technology ensures that crankshafts meet strict manufacturing tolerances and performance standards, which is crucial for engine efficiency and longevity. Additionally, these machines often incorporate safety features such as protective enclosures and emergency stop systems to ensure operator safety during the balancing process.