crankshaft balancing machine for sale

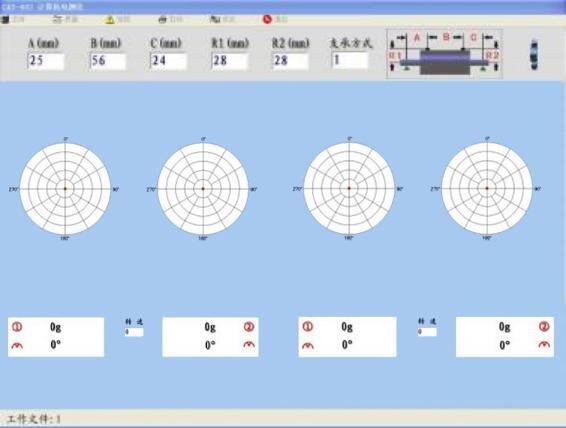

The crankshaft balancing machine represents cutting-edge technology in automotive and industrial maintenance. This precision instrument is designed to detect and correct imbalances in crankshafts, ensuring optimal engine performance and longevity. The machine utilizes advanced sensors and computerized measurement systems to identify even minute irregularities in weight distribution along the crankshaft's rotating axis. Operating through a combination of mechanical and electronic components, it performs both static and dynamic balancing procedures with exceptional accuracy. The system features high-precision measuring capabilities that can detect imbalances as small as 0.1 gram-millimeters. Its robust construction includes hardened steel mounting points and a vibration-isolated base to ensure consistent readings. The machine accommodates crankshafts of various sizes, from small automotive applications to large industrial engines, with adjustable mounting positions and specialized tooling options. The integrated software provides real-time analysis and automated correction recommendations, streamlining the balancing process while maintaining precise quality control standards. This versatile equipment serves multiple industries, including automotive manufacturing, engine rebuilding shops, and heavy machinery maintenance facilities, making it an essential tool for modern engine maintenance and production.