crankshaft balancing cost

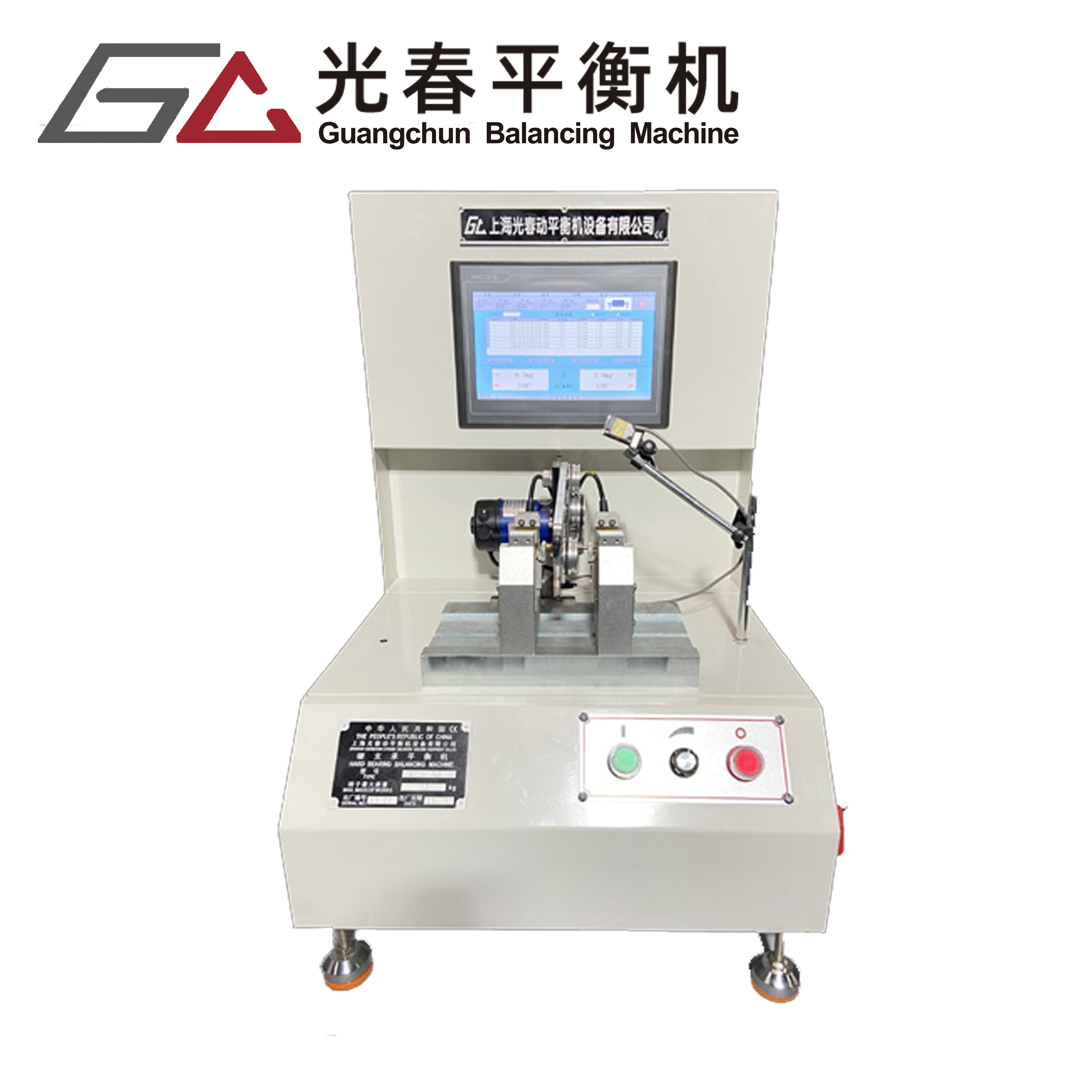

Crankshaft balancing cost encompasses the essential investment required to ensure optimal engine performance and longevity. This critical service involves precise measurements and adjustments to achieve perfect rotational balance in the crankshaft, a fundamental component of any engine. The cost typically ranges from $200 to $800, depending on the engine size, complexity, and service provider. The process utilizes advanced computerized balancing equipment that measures vibrations to within 0.0001 inch, ensuring unprecedented accuracy. Modern balancing technology includes digital sensors, specialized software, and precision machinery that can detect even minimal imbalances. This service is particularly crucial for high-performance engines, racing applications, and rebuilt motors, where optimal balance directly impacts power output and engine life. The cost includes comprehensive testing, weight addition or removal as necessary, and final verification of balance specifications. Professional balancing services often incorporate detailed documentation of before and after measurements, ensuring transparency and quality assurance for customers. The investment in crankshaft balancing significantly reduces engine vibration, prevents premature bearing wear, and maximizes power output, making it an essential consideration for engine builders and performance enthusiasts.