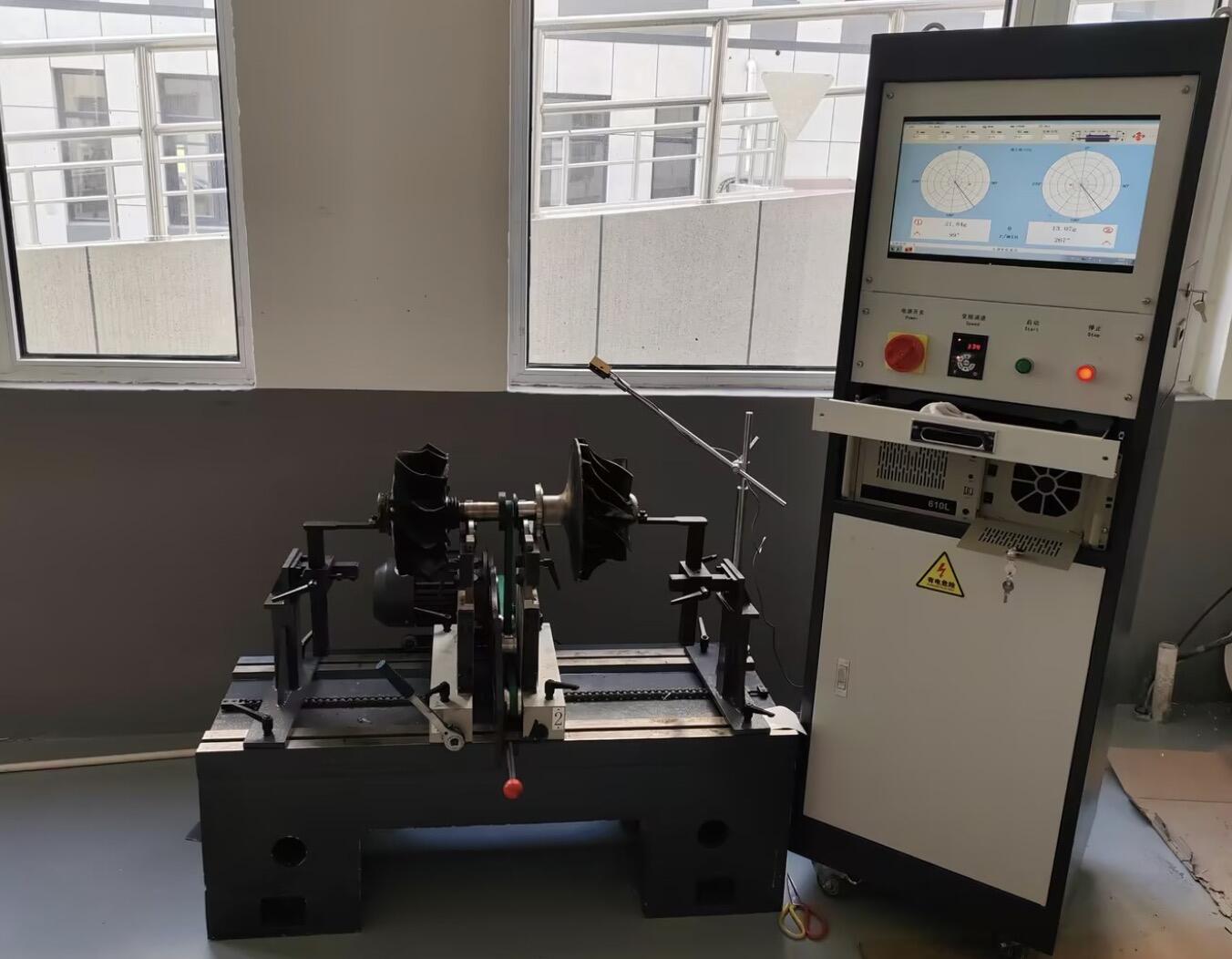

high quality crankshaft balancing

High quality crankshaft balancing is a critical process in engine manufacturing and maintenance that ensures optimal performance and longevity of internal combustion engines. This precision engineering procedure involves carefully measuring and adjusting the weight distribution of the crankshaft to minimize vibration and ensure smooth operation. The process utilizes advanced computer-controlled equipment to detect even minimal imbalances in both dynamic and static conditions. During balancing, technicians measure the crankshaft at multiple points while it rotates at various speeds, identifying areas where weight needs to be added or removed. This sophisticated process considers both the rotating and reciprocating masses of the engine assembly, including connecting rods and pistons. Modern crankshaft balancing equipment can detect imbalances as small as a fraction of a gram, allowing for extremely precise adjustments. The technology employs sophisticated sensors and digital analysis to provide real-time feedback during the balancing process, ensuring that the final result meets strict engineering tolerances. This level of precision is essential for high-performance engines, racing applications, and heavy-duty industrial machinery where reliability and efficiency are paramount.