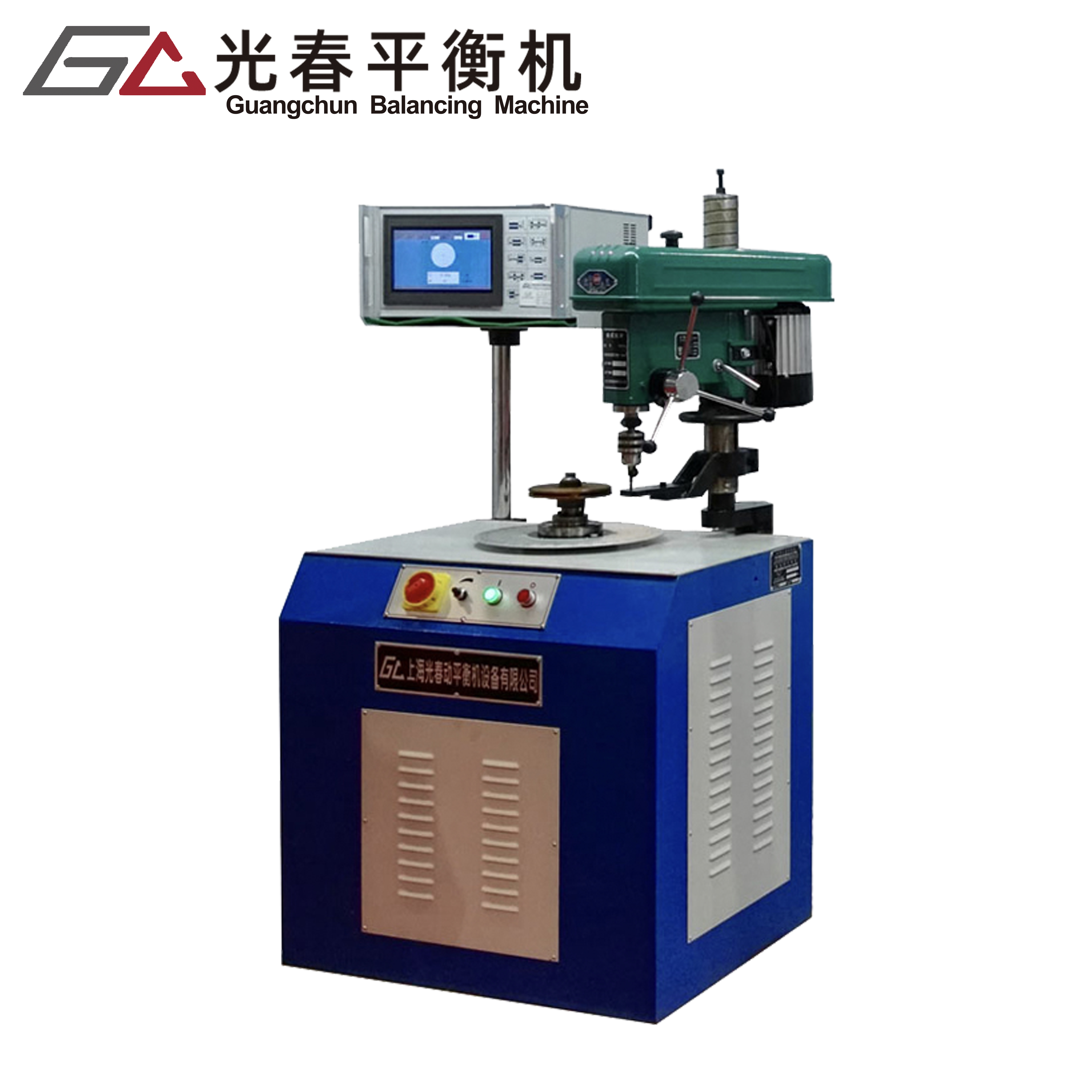

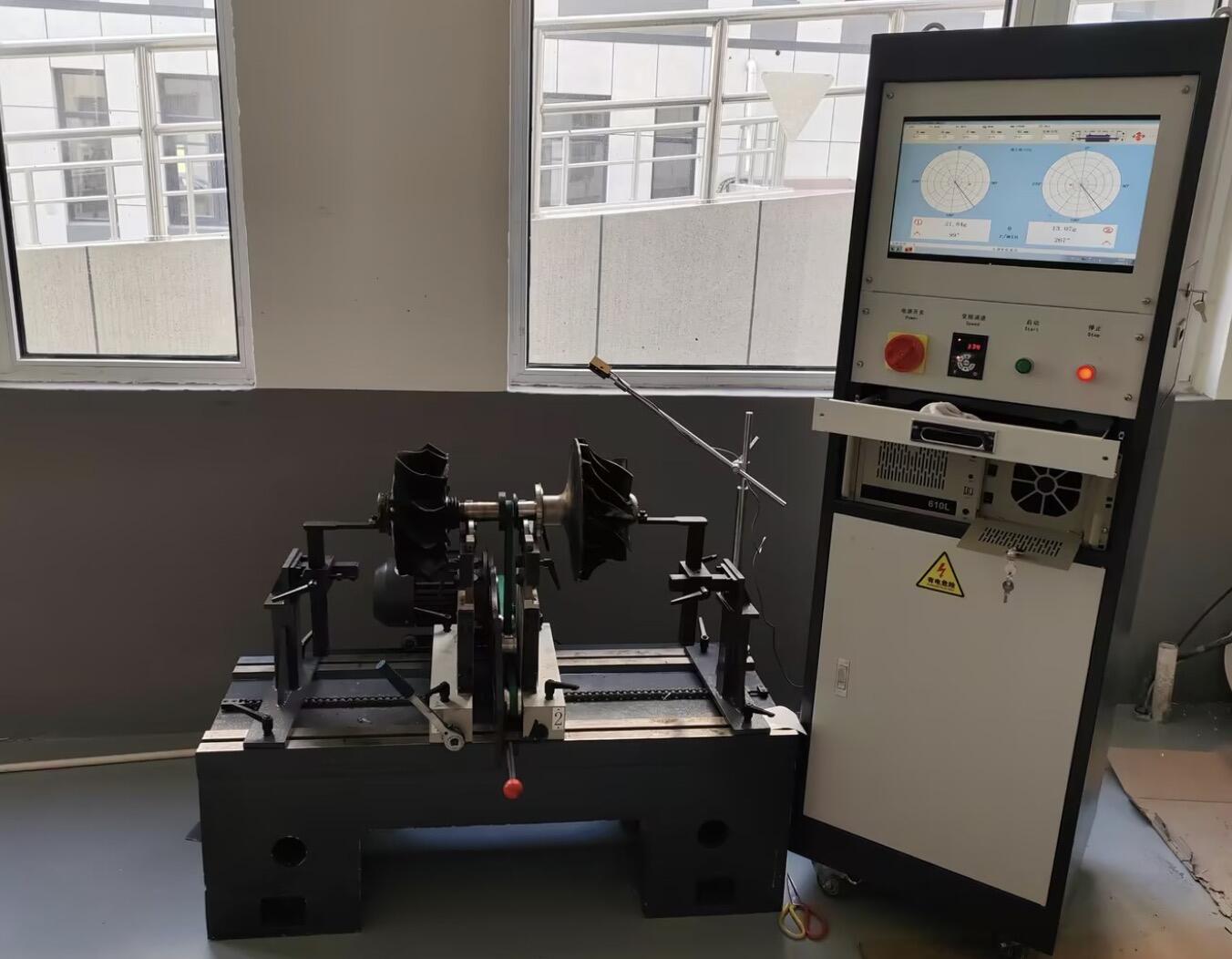

crankshaft balancing machine

A crankshaft balancing machine is a sophisticated piece of equipment essential for ensuring optimal engine performance and longevity. This precision instrument measures and corrects any imbalances in crankshafts, which are crucial components in internal combustion engines. The machine operates by spinning the crankshaft at specific speeds while utilizing advanced sensors to detect vibrations and uneven weight distribution. It employs both static and dynamic balancing techniques to achieve precise measurements down to the gram. Modern crankshaft balancing machines feature computerized controls, digital displays, and automated correction calculations, making the balancing process more accurate and efficient than ever before. These machines can handle crankshafts of various sizes, from small automotive applications to large industrial engines. The technology incorporates laser measurement systems and high-precision bearings to ensure accurate readings and repeatable results. The balancing process involves measuring the distribution of mass around the rotational axis, identifying heavy spots, and determining the exact amount of material that needs to be removed to achieve perfect balance. This equipment is vital in automotive manufacturing, engine rebuilding shops, and maintenance facilities where precise engine component balancing is critical for performance and reliability.